77

Lubrication system

5

Oil pan, replacement (18A-03)

1

Drain the oil. Remove the dip stick. Disconnect the

crankcase ventilation return pipe.

2

Arrange a support for the oil pan if required. Re-

move the screws holding the oil pan against the cyl-

inder block. Lower the oil pan and remove the gas-

ket.

3

Clean the oil pan with fresh kerosene and ensure

that all kerosene is removed. Clean the flange sur-

faces on the oil pan and the cylinder block.

4

If the front or rear main bearing caps have been re-

moved, apply sealing compound according to the in-

structions under point 14 in operation 14A-08.

5

Apply a new oil pan gasket in position on the pan or

the cylinder block. If a two piece gasket is used, ap-

ply the sealing compound on the ends of the re-

spective gasket halves and ensure that the ends

are correctly mounted on each other. Install the oil

pan and ensure correct positioning using a mounting

screw on each side. Install the remaining screws

and tighten all the screws to 22 Nm. Install the

drain plug and washer if required and tighten the

plug to 43 Nm.

6

Install the dipstick. Connect the crankcase ventila-

tion return tube.

7

Fill the oil pan to “MAX” level on the dipstick with an

approved engine oil.

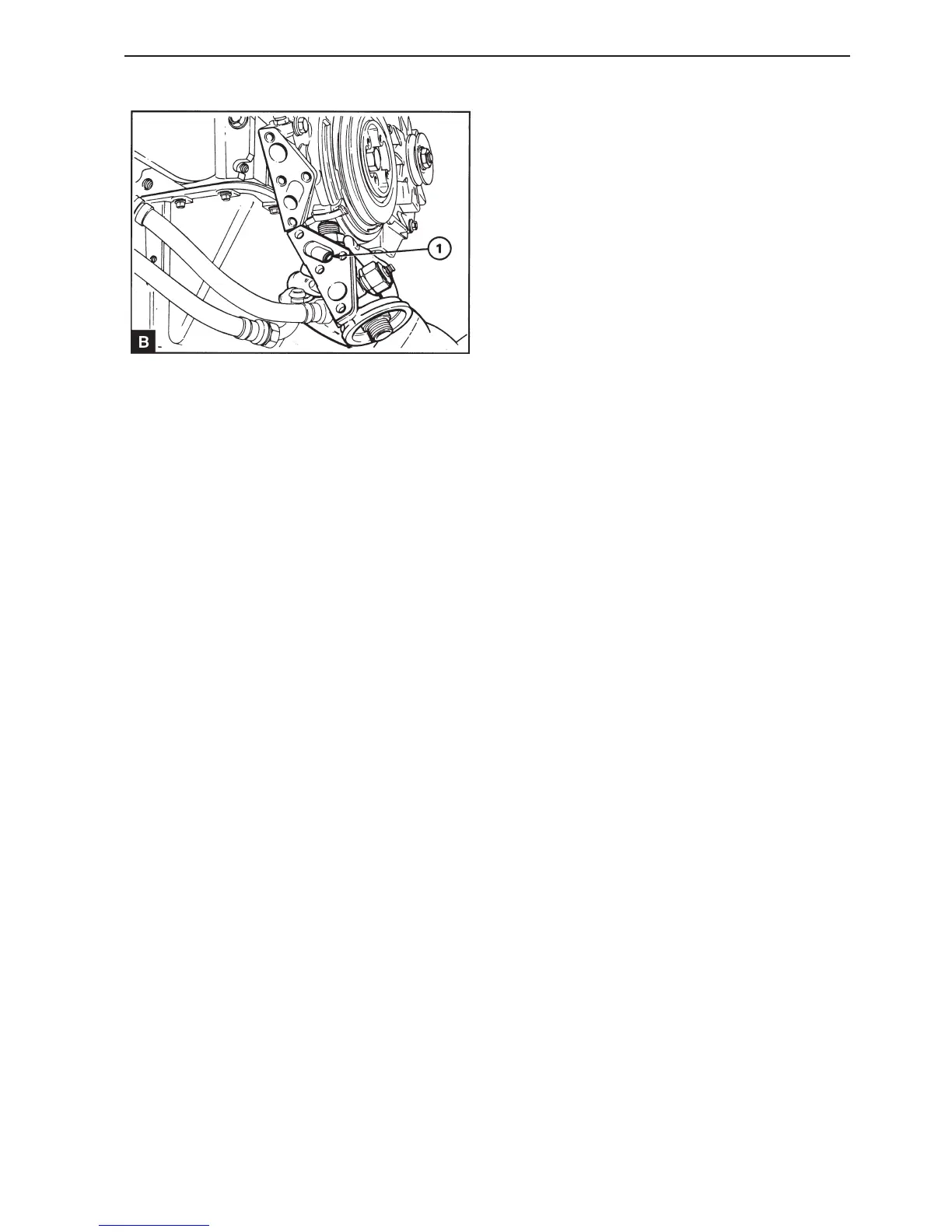

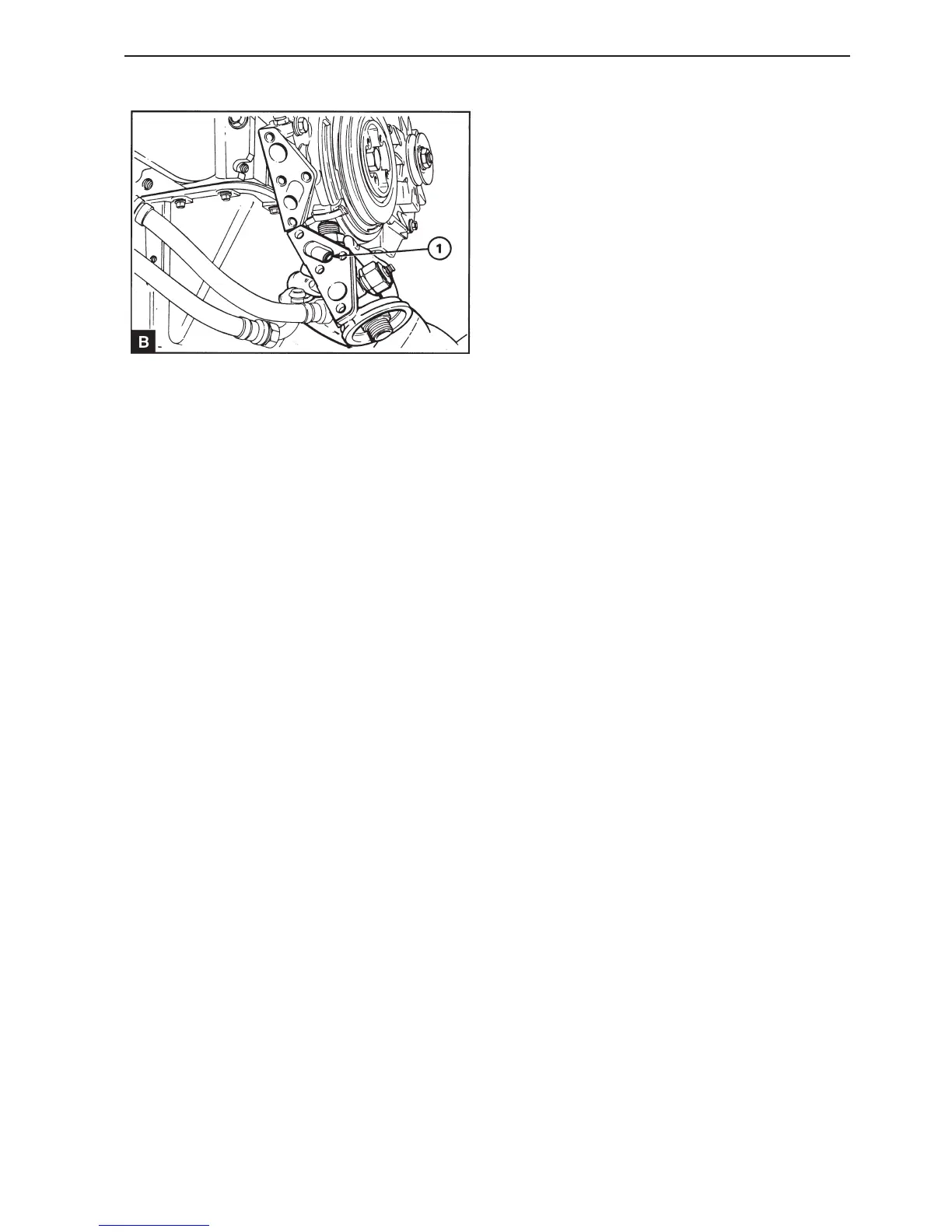

Clean the sealing surfaces on the oil filter adapter

and the oil pump.

If an oil cooler is used ensure that a plug is installed

in the oil filter adapter (B1).

6

Install the oil filter adapter with a new gasket

against the oil pump and tighten the mounting

screws to 22 Nm.

7

Connect to the oil cooler pipe and /or the pipe to the

turbocharger if required.

8

Install a new oil filter, operation 18A-01.

Loading...

Loading...