69

Cylinder block

27

Install the cylinder head assembly, operation 12A-

07.

28

Install the fuel filter, injectors and fuel injection

pump, see section 19.

29

Install the oil pump and filter unit, operation 18A-06.

30

Install the timing cover, belt pulleys and the timing

belt, see section 15. Install the crankshaft pulley,

operation 14A-01A. Adjust the timing belt tension,

operation 15A-01.

31

Remove the adjustment drifts and turn the crank-

shaft two revolutions. Check the fuel injection pump

setting, operation 17A-03. Install the cap of the tim-

ing cover, operation 15A-01.

32

Install the starter motor, operation 22B-01.

33

Install the generator (GEN) drive belt, the generator

(GEN) and the mounting brackets, see 22.

34

Install the engine.

35

Fill the engine coolant system.

36

Fill the oil pump to the correct level with an ap-

proved engine oil.

37

Bleed the fuel injection system, operation 19A-08.

Cylinder block, inspection

(16A-02)

1

Clean the coolant and lubrication channels.

2

Check the cylinder block for cracks and other dam-

age.

The upper surface of the cylinder block cannot nor-

mally be machined, because it affects the height of

the pistons above the cylinder block surface. If high

pistons (height class 1) are installed in all cylinders

it is possible to machine a maximum of 0.26 mm

from the upper surface of the cylinder block and in-

stall low pistons (height class 6). If the block is ma-

chined the piston height must be checked to ensure

that the pistons do not reach further than the maxi-

mum permitted limit, otherwise the pistons may hit

the valves and damage the engine.

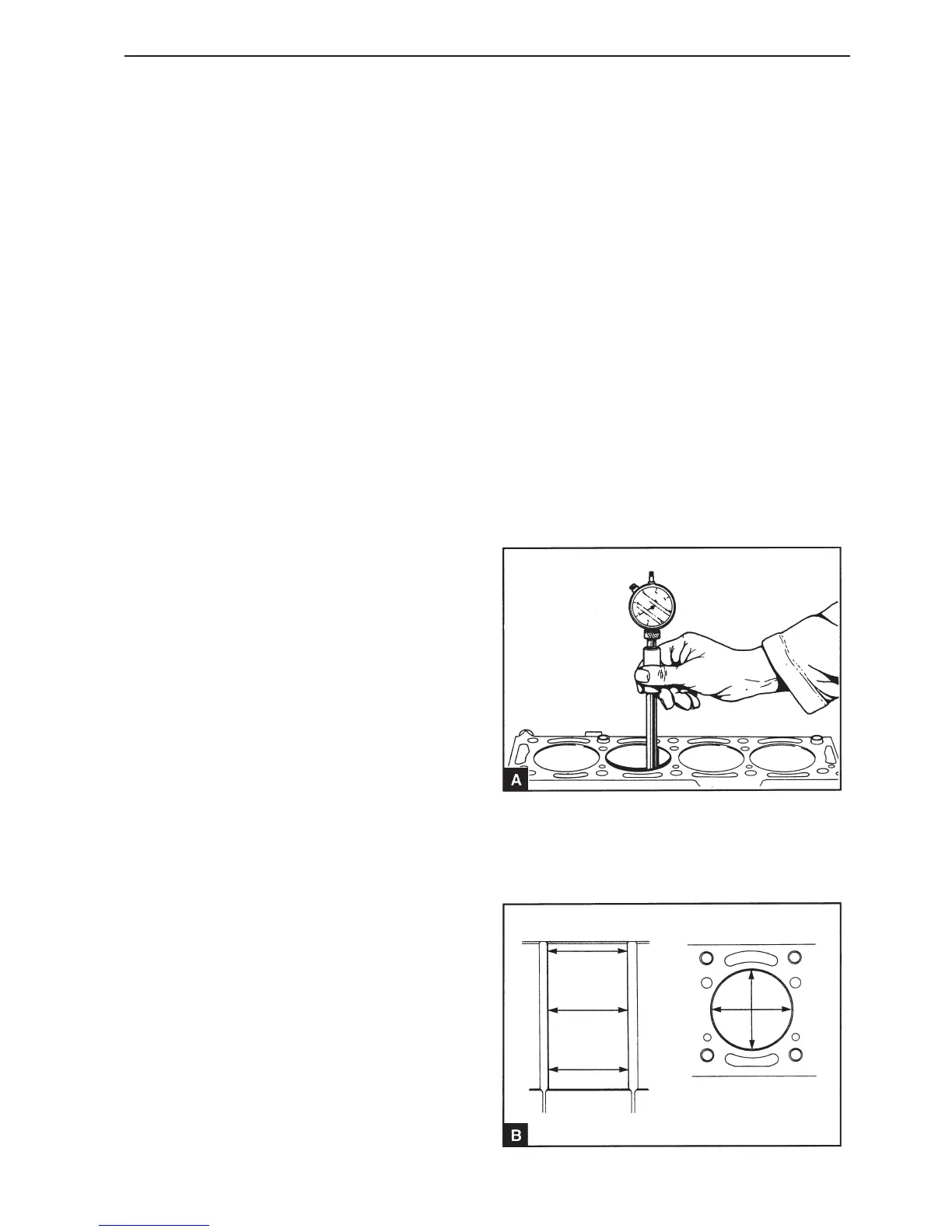

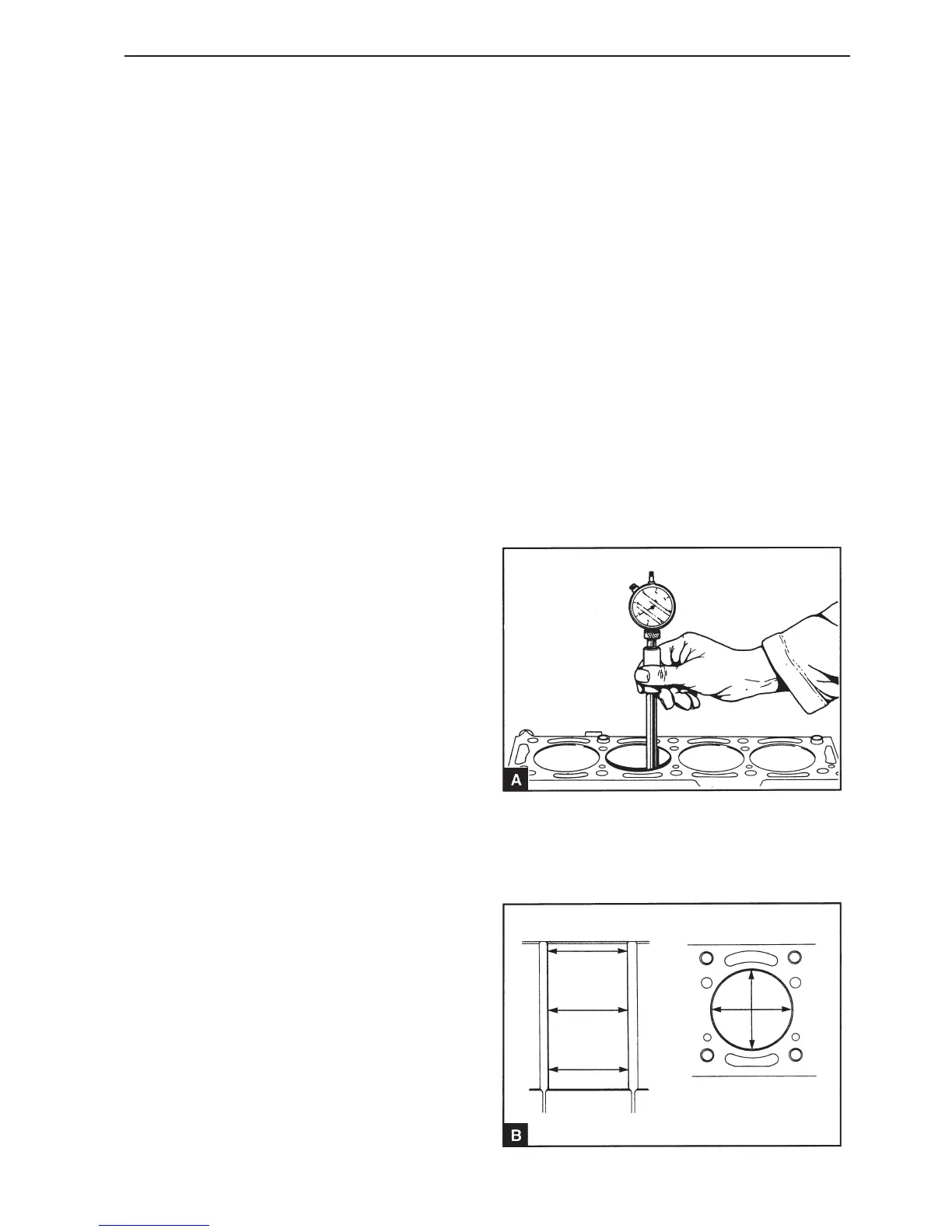

3

Check the cylinder bore for wear (A) and damage.

The top, bottom and center of the cylinder bore

should be inspected in both the vertical and lateral

planes (B).

Loading...

Loading...