90

Fuel injection system

9

Check that the key is correctly installed on the

pump shaft. Install the fuel injection pump in posi-

tion with the locknuts sufficiently tightened to hold

the pump secure, but not so much that it prevents

radial movement in the housing. Install the screws

holding the support bracket against the rear end of

the pump and finger tighten them.

10

Install the pulley on the shaft with the key in the

correct keygroove, see operation 15A-05. Hold the

belt so that it does not move and install the pulley

nut and washer. Tighten the nut so that the pulley is

pressed up on the shaft, do not tighten the nut to

the final torque.

11

If the pump shaft is installed in top dead center po-

sition (see “Note!” above): Ensure that the tooth

with the correct marking turned towards the arrow

on the timing cover and install the timing belt, see

operation 15A-04. Check the position of the journals

in the cut out in the pump mounting flange. Check

that the fuel injection pump can be turned clockwise

seen from the rear when the belt tension is adjust-

ed. If there is not sufficient room for movement

change the position of the belt on the pulley. Adjust

the timing belt tension, operation 15A-03. Check

that the journals are not in the end of the groove in

the pump mounting flange and tighten the locknuts.

Unscrew the mounting screw on the side of the

pump and install the spacer under the screw.

Tighten the mounting screw to 12 Nm. Tighten the

nut for pump pulley to 60 Nm. Check the fuel injec-

tion pump adjustment, operations 17A-03.

If the pump shaft is not secure: Ensure that the

tooth with the correct marking turned towards the

arrow on the timing cover and install the adjustment

drifts through the smooth holes in the pump pulley.

Install the timing belt, see operation 15A-04 and re-

move the adjustment drifts. Adjust the belt tension,

operation 15A-03. Tighten the nut for pump pulley to

60 Nm. Adjust the pump setting, operation 17A-03

and tighten the pump flanged nuts.

12

Tighten the screws holding the support bracket at

the rear of the pump against the installation bracket.

13

Check that the adjustment drifts are removed.

14

Install the cap of the timing cover, operation 15A-

01.

15

Install the low pressure lines. Certain pumps have a

banjo screw, which is marked “OUT” and this must

be installed at the fuel return connection at the tank.

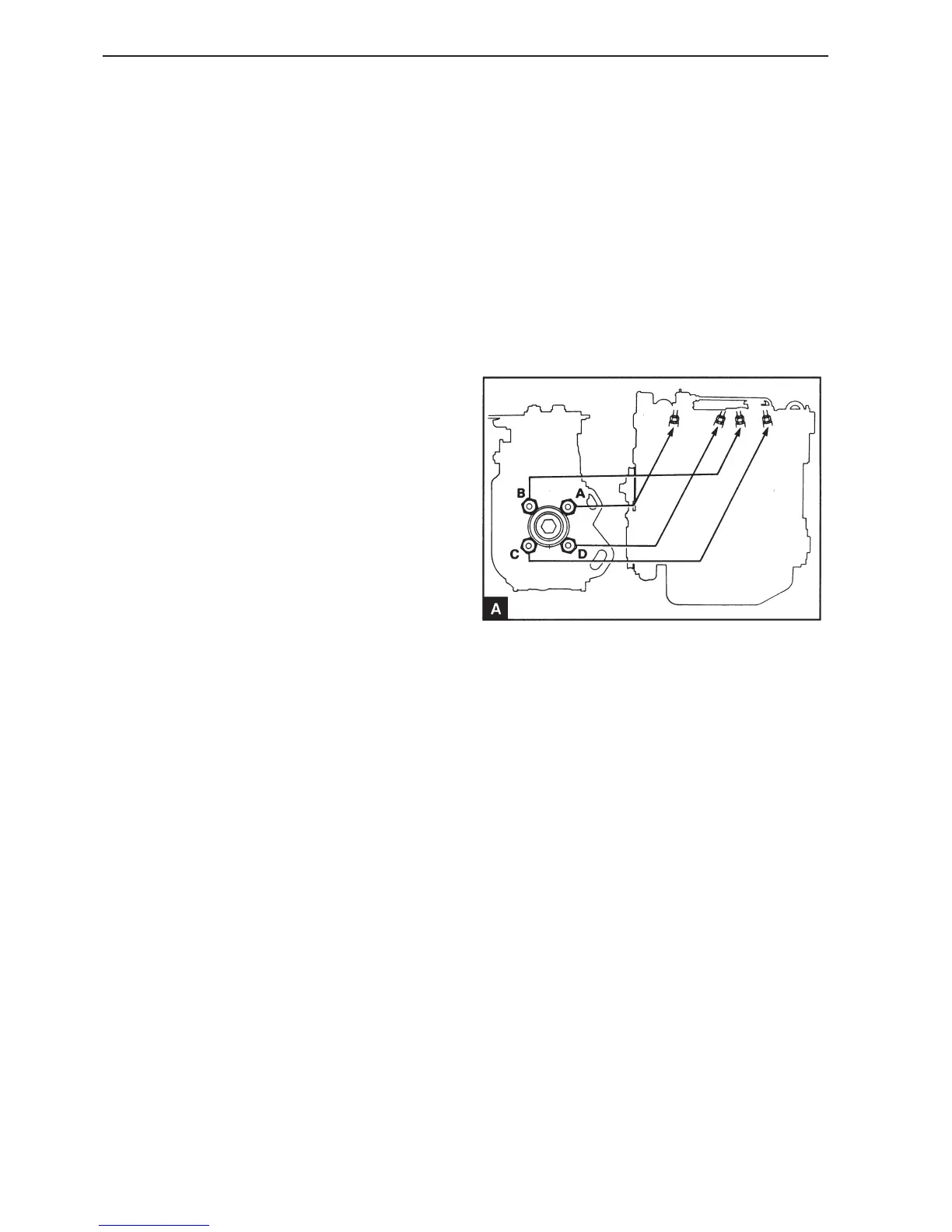

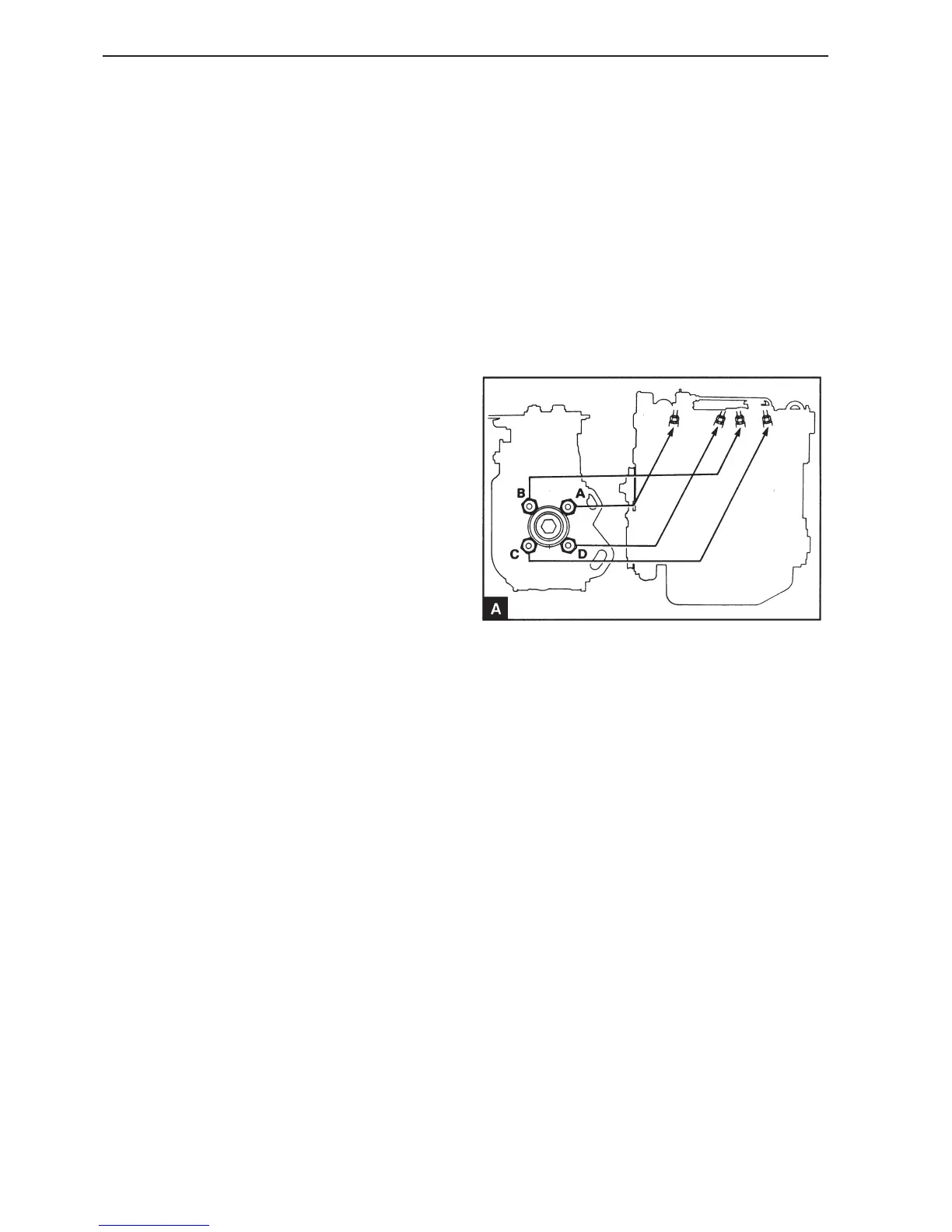

16

Install the delivery pipes to the pump. Use a wrench

to prevent the output terminals on the fuel pump

(FP) from moving when the delivery lines are in-

stalled. The connections to the pump are as dis-

played in illustration A. Do not tighten the connector

to the injectors until the system has been bled.

17

Connect the engine speed regulator to the fuel

pump (FP) and connect the stop control if required.

Connect the cables for the stop solenoid on the

pump. Connect the battery.

18

Bleed the fuel injection system, operation 19A-08.

Loading...

Loading...