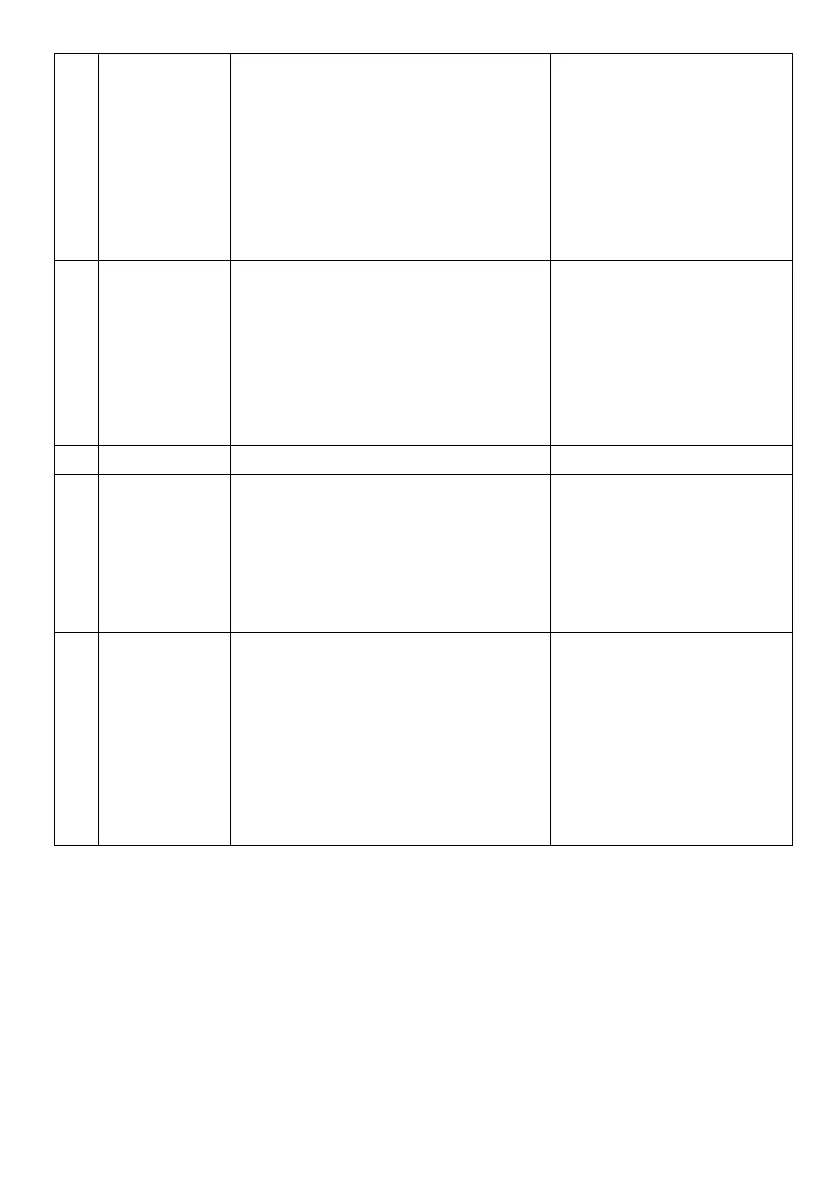

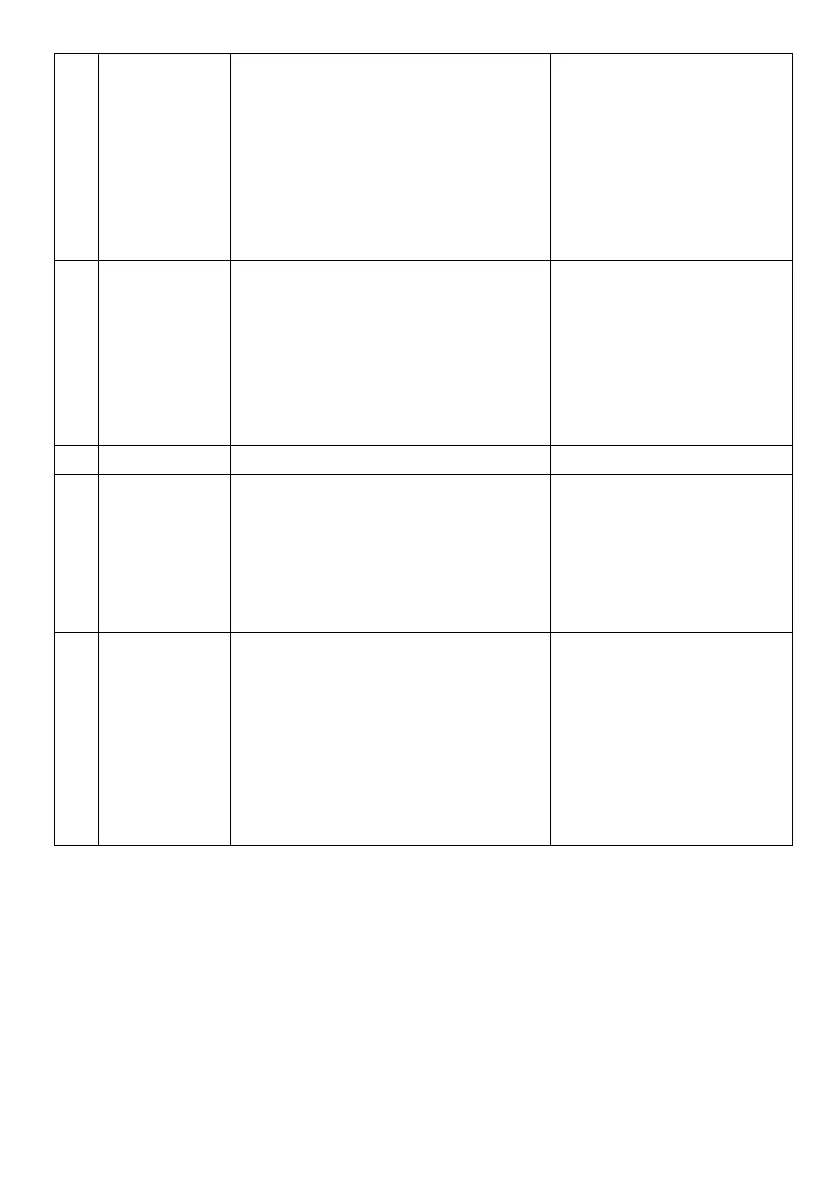

V 810 Chapter 5 Checking and removing errors

88

The motor

does not

rotate after

the inverter

runs.

1: Check the motor and the motor

cables.

2: The inverter parameters are set

improperly (motor parameters).

3: The cable between the drive board

and the control board is in poor

contact.

4: The drive board is faulty.

1: Ensure the cable

between the inverter and

the motor is normal.

2: Replace the motor or

clear mechanical faults.

3: Check and re-set motor

parameters.

The S-

terminals are

blocked

1: The parameters are set incorrectly.

2: The external signal is incorrect

3: The jumper bar between OP and

+24 V becomes loose.

4: The control board is faulty.

1: Check and reset the

parameters in group P5.

2: Re-connect the external

signal cables.

3: Check the jumper bar

between OP and +24 V.

4: Find technical support

The inverter

reports

overcurrent

and

overvoltage

frequently.

1: The motor parameters are set

improperly.

2: The acceleration/deceleration

time is improper.

3: The load fluctuates.

1: Again set the motor or

auto-tuning parameters.

2: Set proper acceleration/

deceleration time.

3: Find technical support

RAY is

indicated

when the

power or

inverter is

turned on.

The contactor of soft starter is not

excitated.

1: Check whether the

contactor cable is loose.

2: Check whether the

contactor is faulty.

3: Check whether 24 V

power supply of the

contactor is faulty.

4: Find technical support

Loading...

Loading...