5-22 BA 5001-6001 US – Edition 1.2 * 6001b520.fm

Maintenance

Changing hydraulic oil

Important

Only change the hydraulic oil if it is warm (about 50 °C/122 °F).

Lower the dump bucket in center position before draining the oil (dumper in

straight-ahead position).

Environment

Dispose of the old hydraulic oil by an ecologically safe method.

☞ Open the drain plug to let the oil drain into a container.

☞ Check the hydraulic oil tank for contamination and clean if necessary.

☞ Replace the filter according to the maintenance specifications.

☞ Screw the drain plug back in correctly.

☞ Add clean hydraulic oil through the strainer – see Filling up hydraulic oil on page 5-21.

☞ Close the hydraulic oil tank correctly.

☞ Let the machine run at idling speed without load for some minutes.

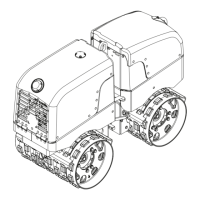

Fouling indicator for hydraulic oil filter

A red indicator on the instrument panel monitors the filter.

Replace the filter:

• If the indicator comes on when the hydraulic oil is at operating temperature.

• According to the maintenance interval.

In cold weather the indicator can come on immediately when the engine is started. This is

caused by increased oil viscosity. In this case:

☞ Let the engine run at idling speed for about 2 minutes.

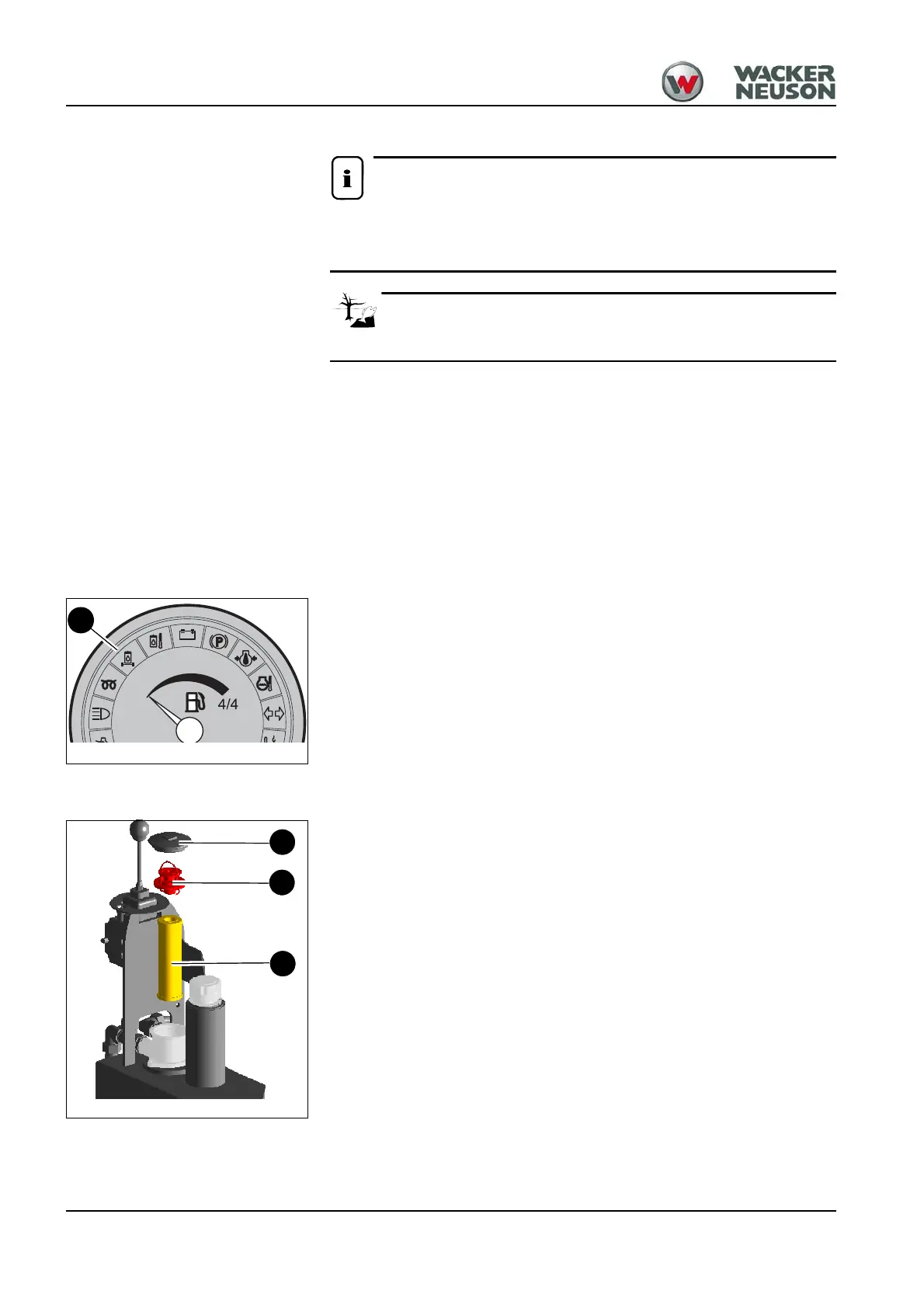

Replacing the hydraulic oil filter element

Proceed as follows:

☞ Stop the engine

☞ Open cover 1 by about 2 turns and wait until the oil level in the filter housing drops to

the oil level in the hydraulic oil tank.

☞ Open the cover completely and remove it.

☞ Pull filler pipe 2 upward with a slightly turning movement, together with filter element 3.

☞ Remove the filter element from the filler pipe and dispose of it.

☞ Slide the filler pipe onto the new filter element and insert it in the filter.

☞ Tighten the cover by hand.

Fig. 86: Fouling indicator for hydraulic oil filter

4

Fig. 88: Hydraulic return filter

1

2

3

Loading...

Loading...