50

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

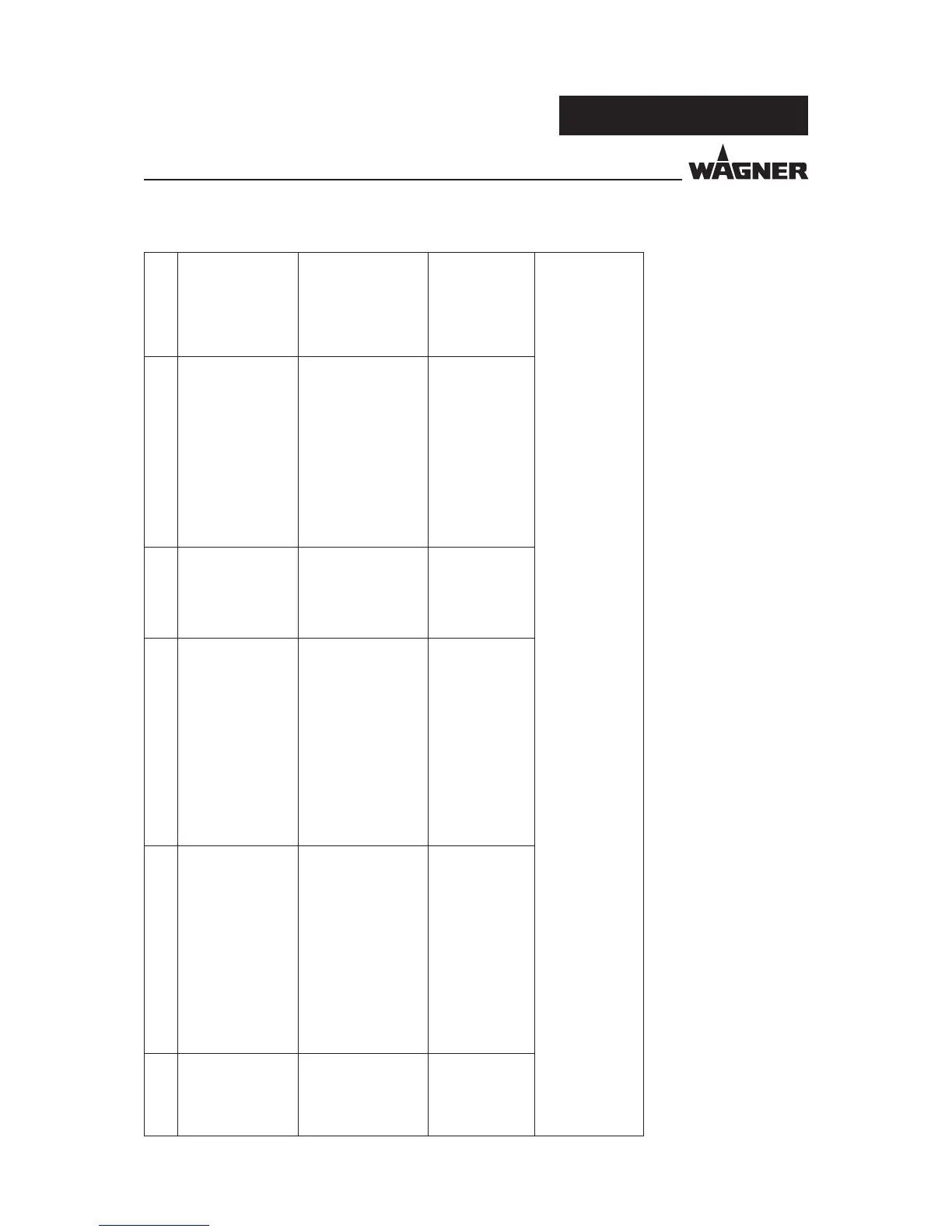

9.1 OVERVIEW OF INSPECTIONS

Section Type of inspection Requirements Inspection by Type of inspection Inspection

interval

1 Resistance to ground of work

piece's locating point

The resistance to ground of

every work piece's locating point

must not exceed 1 megohm

(measurement voltage must be

1000 V). The design of the work

piece receiver must ensure that the

adapters remain grounded during

coating.

CP ME/CI

Measure resistance to ground

(work piece receiver - ground

potential)

max. 1 megohm @ 1,000 V.

weekly

2 Interlock between technical

ventilation and high-voltage,

compressed air and coating product

supply

The technical ventilation should

be interlocked such that the

powder feed and high-voltage

cannot be switched on, while the

technical ventilation is not working

e ectively.

CP FI

Test whether the system is safely

stopped and the product supply,

supply air and high-voltage

are switched o when the

ventilation is shut down.

annually

3 Checking the electrostatic manual

coating system for damage

Electrostatic manual coating

systems may only be operated in an

undamaged condition. Damaged

devices must be decommissioned

immediately and repaired

immediately.

CP FI

Inspect and test

(e.g., by measurement) whether

all parts carrying high-voltage

do not result in discharge which

puts people at risk.

weekly

Legend:

MA = Manufacturer

EM = Employer

CP = Capable person

FSE = Fire safety engineer

ELC = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

SI = Standard inspection

VI = Visual inspection

CI = Continuous inspection

TI = Technical inspection

Loading...

Loading...