Page 103

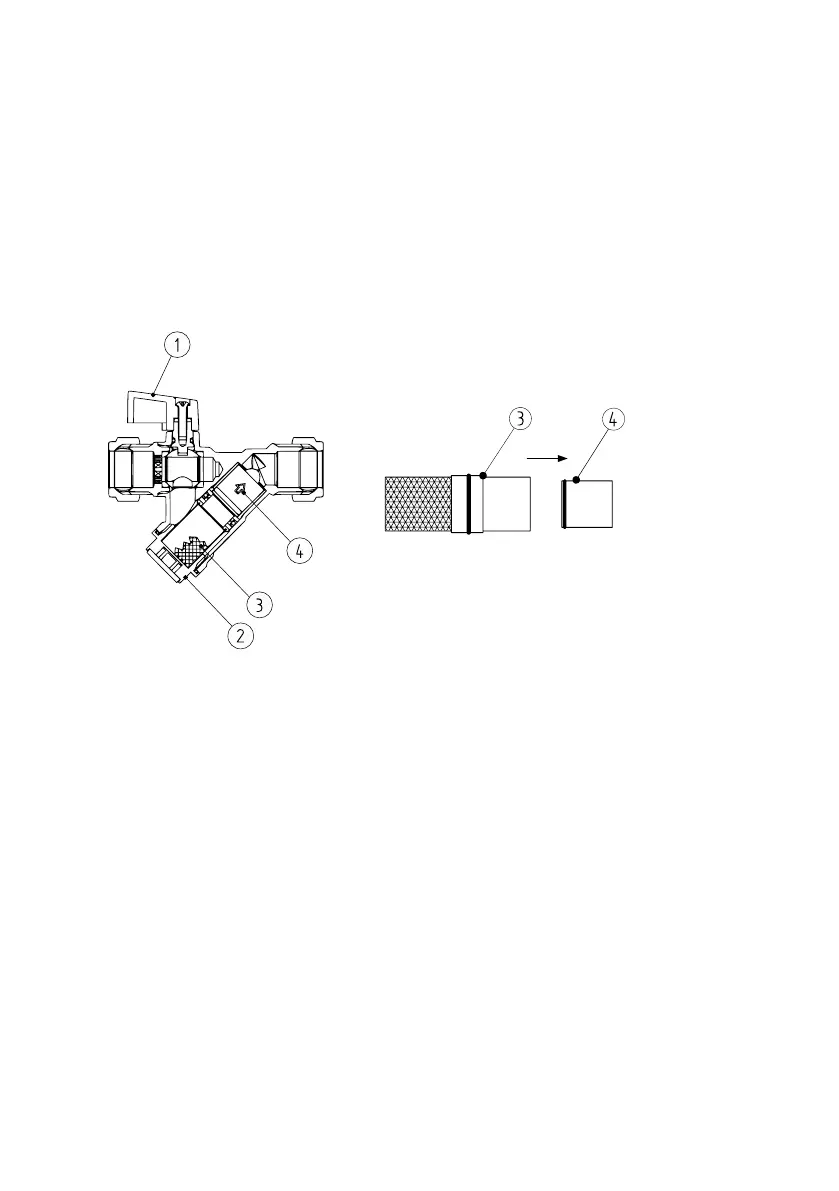

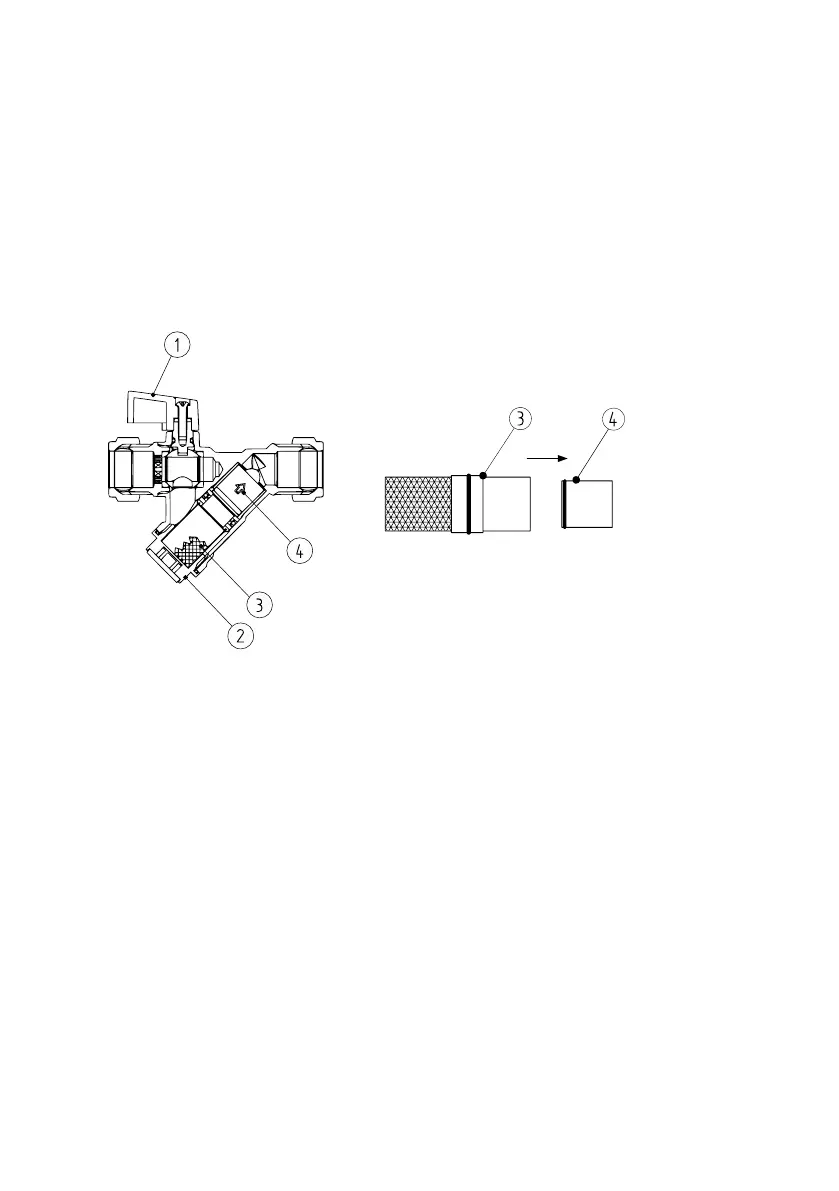

10.3.4 Flow Restrictor

An 18l/min flow restrictor has been factory fitted to the incoming DCW isolation valve, but can

be easily removed if required.

1. Isolate the incoming DCW supply using the ball valve (1).

2. Remove the cap and O ring (2) using a spanner, expect an escape of residual water.

3. Withdraw the combined strainer element (3) and flow restrictor (4) assembly.

4. Remove the flow restrictor cartridge from the strainer element, and replace the strainer

element back into the valve body.

5. Replace the cap, ensuring the O ring is seated correctly.

6. Turn on the incoming DCW supply.

10.3.5 Pipework

All pipework including pipework within the casing should be insulated after the boiler has been

installed. Suitable pipe insulation with a minimum wall thickness of 19mm should be used

wherever possible. For exterior pipework insulation, please see the latest local building

regulations for details.

10.3.6 Balanced flue

Due to the relatively high ambient temperature within the Combination Boiler casing, a balanced

flue should be fitted in order to draw in cooler outside air. For external models, an air inlet

adapter, AID, is available from Warmflow.

10.3.7 Plinth / Base

The boiler should be installed on a plinth or base with a thermal break such as non-combustible

solid insulation. This is to minimise heat transfer to the ground and maximise the overall

efficiency of the boiler.

Loading...

Loading...