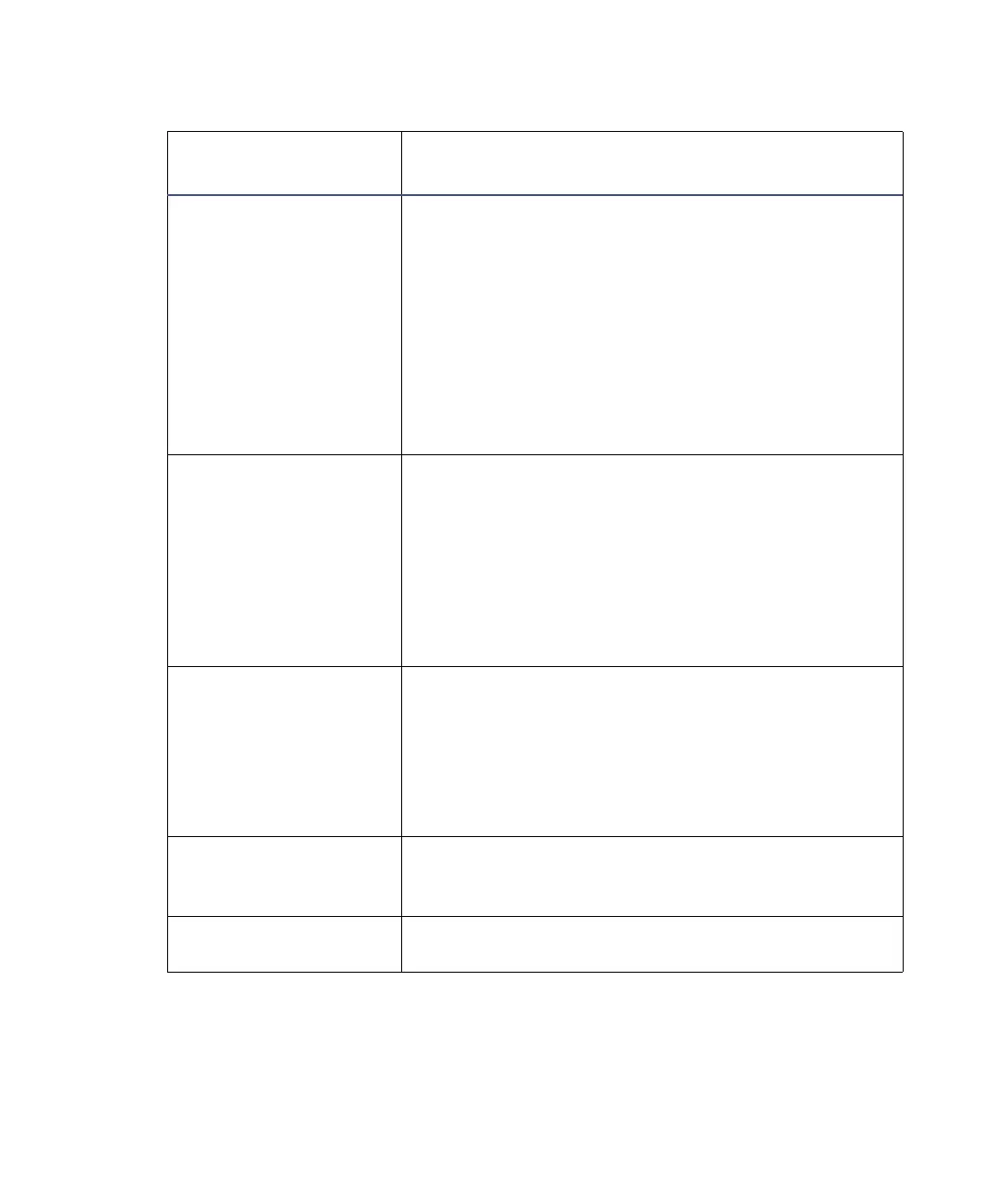

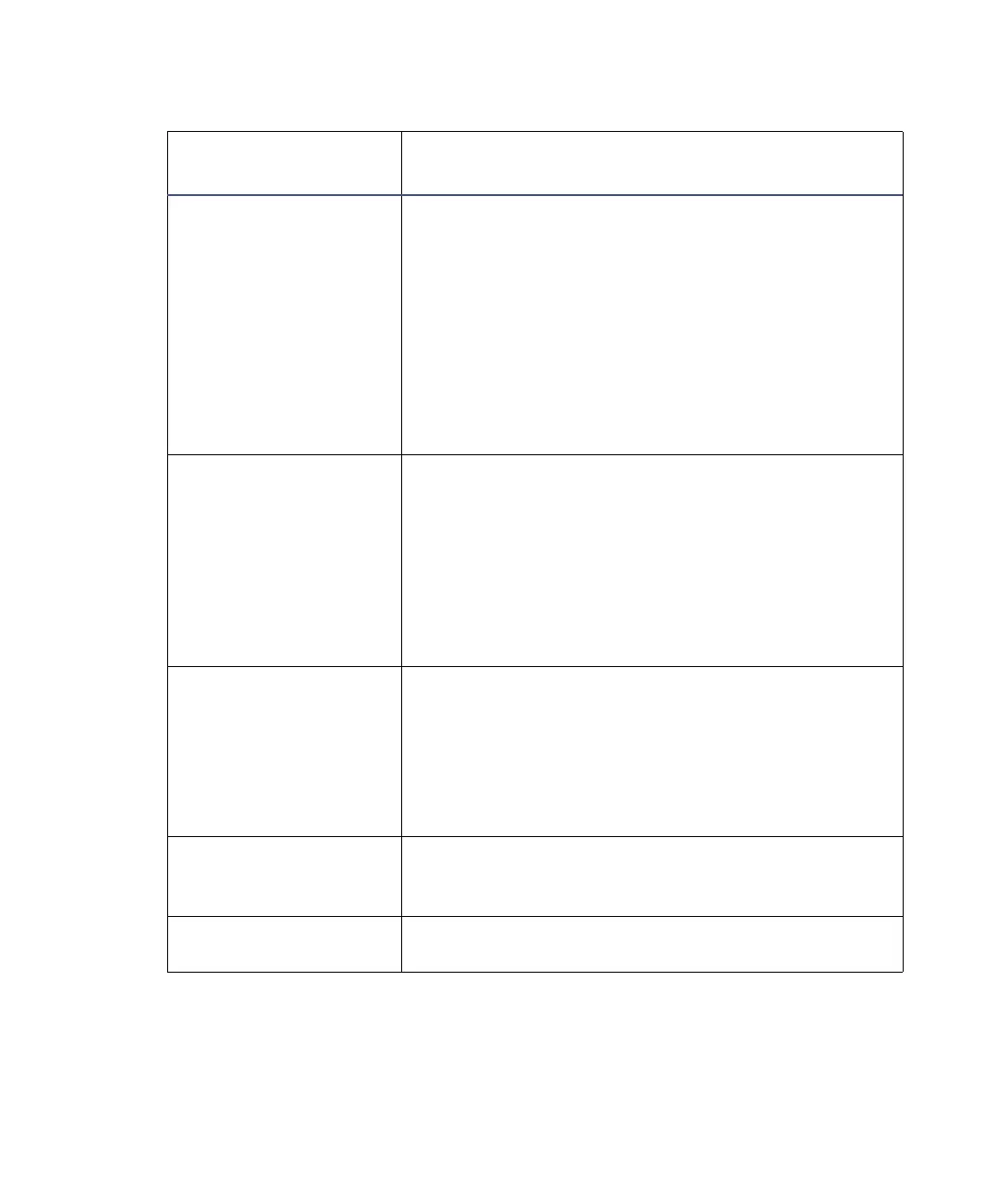

4Maintenance Procedures

44 July 7, 2014, 715003736IVD Rev. C

Replace the in-line

filter

As needed. The typical failure modes are as follows:

•High back pressure. The in-line filter causes a

high pressure shutdown. In this case, disconnect

the in-line filter. If the system exhibits pressure

decay, check the system pressure at known

conditions. Replace the frit or entire check valve

assembly.

•Leak. This can be detected visibly, using the leak

sensor, or by noticing that peak retention times

vary.

Replace the

accumulator check

valve

Replace as part of the annual scheduled routine

maintenance and, thereafter, as needed. The

typical failure modes are as follows:

•Late eluting peaks are exhibited and/or after a

dynamic leak test was performed where the leak

rate is above the acceptable limit.

•The solvent manager exhibits a low or erratic

flow rate/ pressure pulsations.

Replace solvent

reservoir filters

Replace as part of the annual scheduled routine

maintenance and, thereafter, as needed. The

typical failure modes are as follows:

•Slow baseline drift is exhibited.

•Retention times are increasing.

•The system exhibits low erratic system pressure.

Clean the air filter in

the door

Perform as part of your annual routine scheduled

maintenance and when solvent or dust

accumulates.

Replace the air filter in

the door

Replace annually.

Binary Solvent Manager maintenance procedures: (Continued)

Maintenance

procedure

Frequency

Loading...

Loading...