Watlow Series F4P Features ■ 7.17

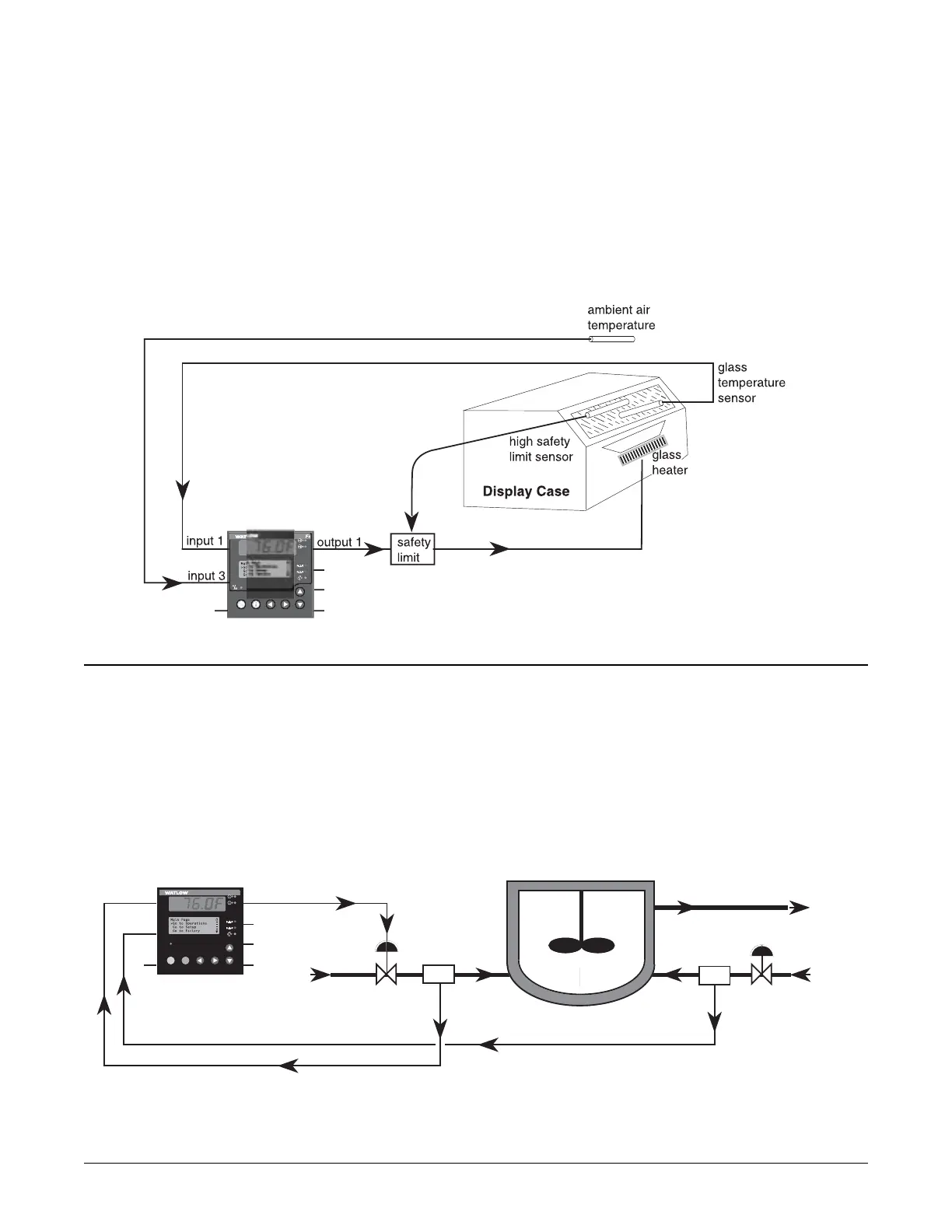

Differential Control

The Series F4P with the enhanced control option can be

configured to support differential control. Differential

control allows the Series F4P to control one process at a

difference to another process.

Analog input 3 is configured as the differential input.

The process value measured on input 3 is added to the

differential value [Set Diff.] to become the closed-loop

control set point [CTL SP]. Four additional differential

values (Dgt. Diff. Value) can be enabled remotely through

designated digital inputs. The nameable digital differen-

tial values are entered in the Operations Menu > Control

Set Points.

Differential control is only available in enhanced control

operation. Changes to the differential value or Analog In-

put 3 during auto-tune are not acted on until the auto-

tune process is completed or aborted.

Location in software: Setup Page > Analog Input 3 and

Setup Page > Digital Input x (1 to 4).

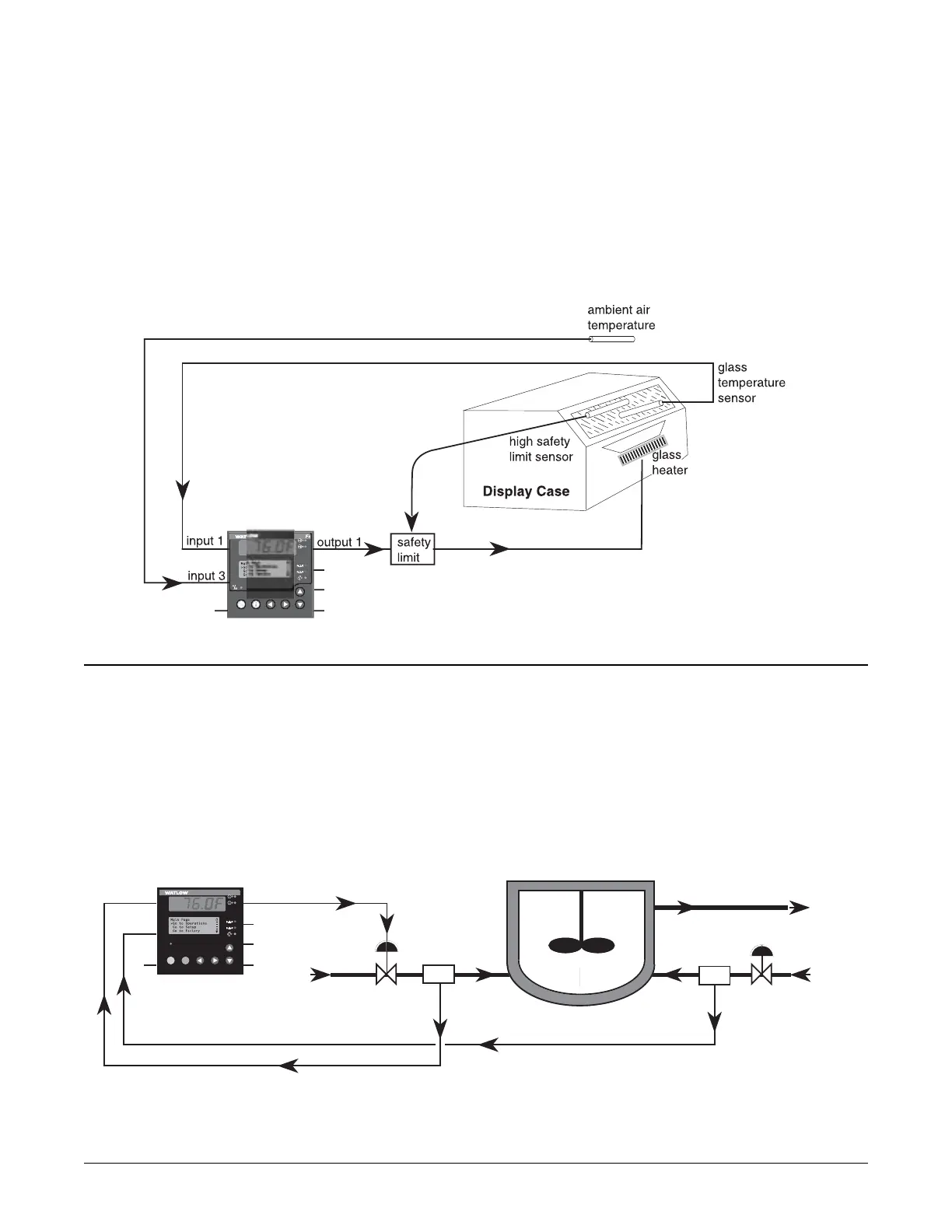

Ratio Control

The Series F4P with the enhanced control option can be

configured to support ratio control, which is especially

useful in applications that mix materials.

Analog input 3 is configured as the ratio input. The pro-

cess value measured on input 3 multiplied by the ratio

value [Set Ratio] becomes the closed loop control set

point [CTL SP]. Four additional ratio values (Dgt. Ratio

Value) can be enabled remotely through designated digi-

tal inputs. The nameable digital ratio values are entered

in the Operations Menu > Control Set Points.

Ratio control is only available in enhanced control opera-

tion. Changes to the ratio value or analog input 3 during

auto-tune are not acted on until the auto-tune process is

completed.

Location in software: Setup Page > Analog Input 3 and

Setup Page > Digital Input x (1 to 4).

Figure 7.17a — Differential Control Application Example.

Figure 7.17b — Ratio Control Application Example.

Loading...

Loading...