Part number 550-142-903/1016

39

!LLOWABLEVENTAIRPIPEMATERIALS

LENGTHS

Use only the vent materials and kits

listed in Figure 40, page 33. Provide

pipe adapters if specified.

1. Locate the termination such that the total air

piping and vent piping from the boiler to the

termination will not exceed the maximum

length given in Figure 39, page 32.

$ETERMINETERMINATIONLOCATION

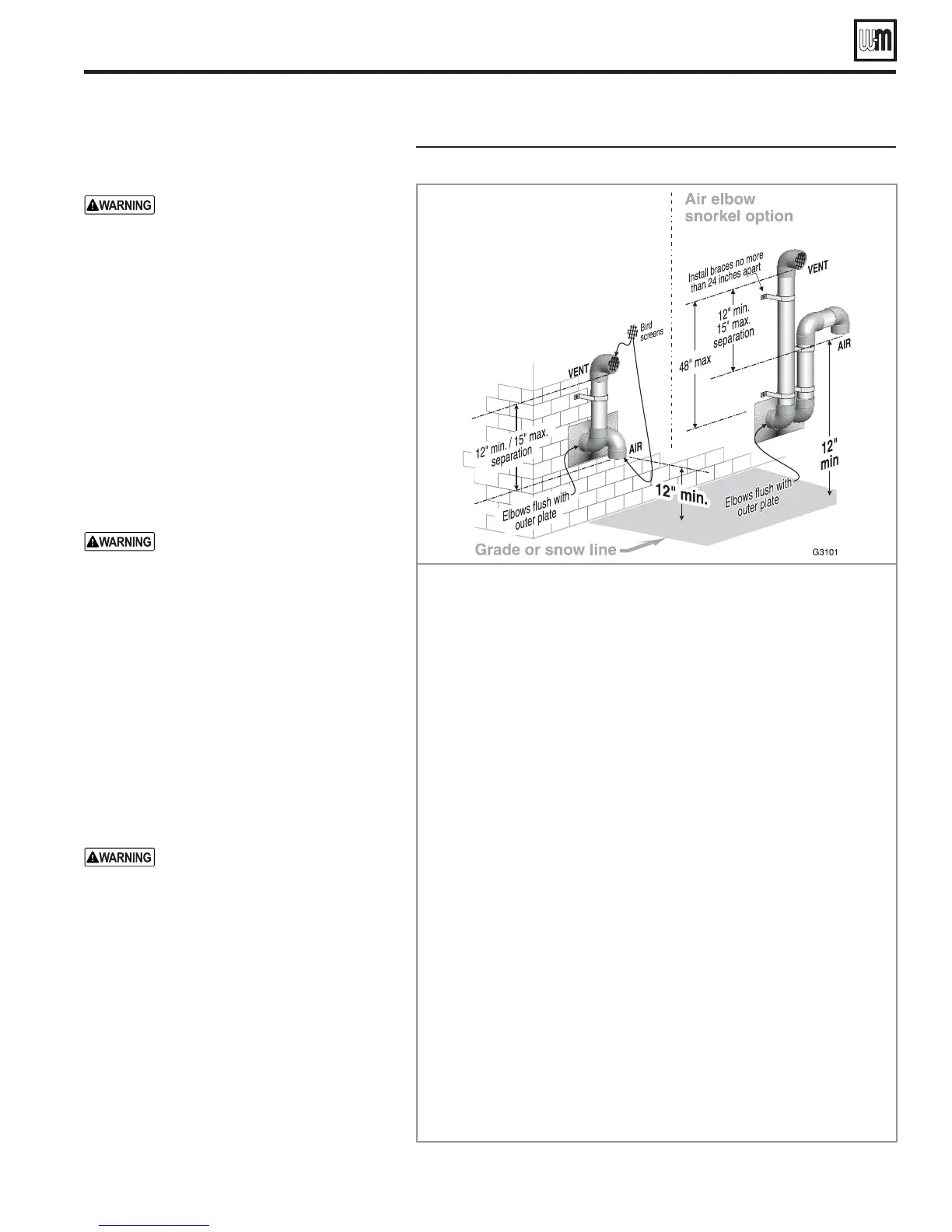

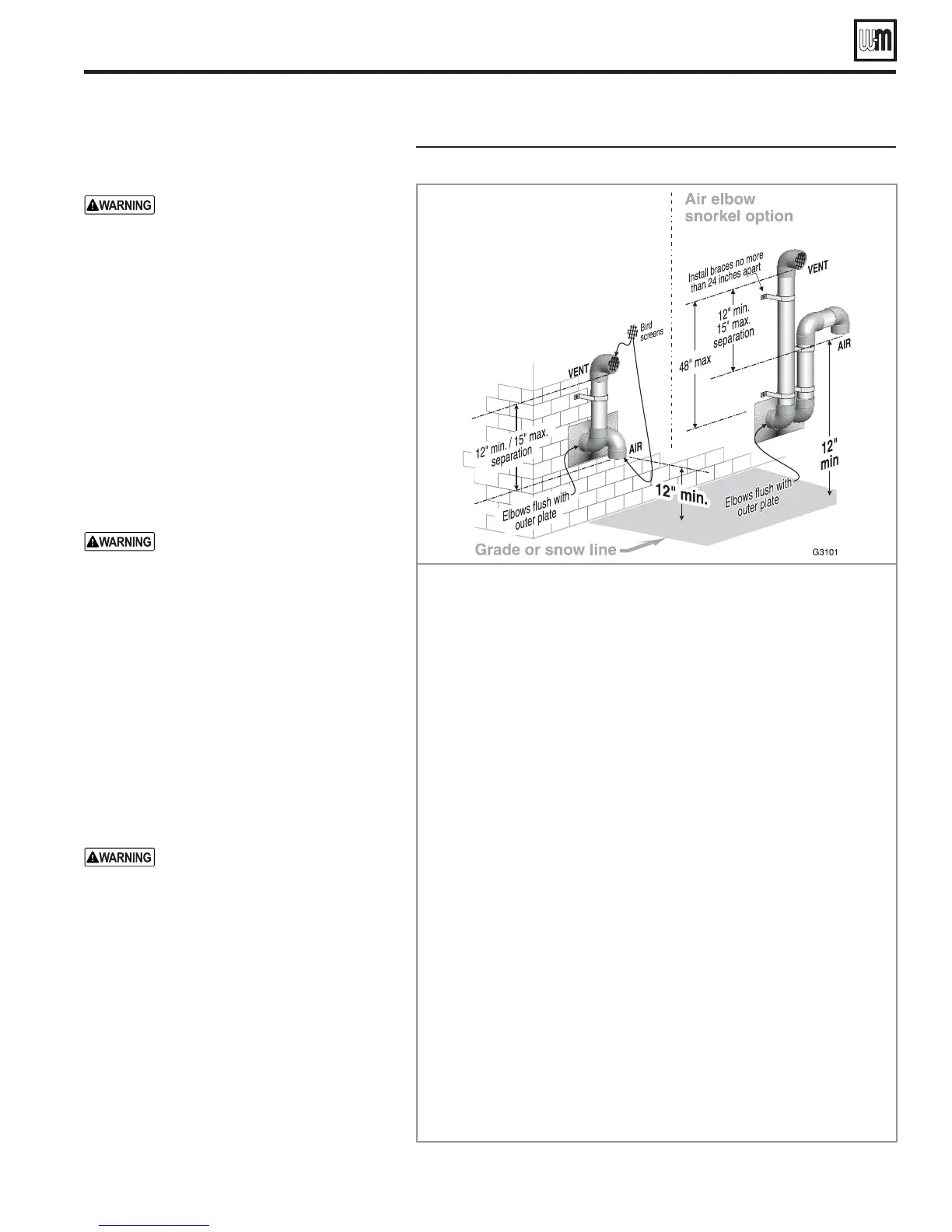

1. The air and vent terminations must be in-

stalled as shown in Figure 47, page 39 and

Figure 49, page 40.

2. The terminations must comply with clearances

and limitations shown in Figure 41, page 35.

3. Locate the terminations so they are not likely

to be damaged by foreign objects, such as

stones or balls, or subject to buildup of leaves

or sediment.

Do not exceed the maximum lengths

of the outside vent piping shown in

Figure 47, page 39. Excessive length

exposed to the outside could cause

freezing of condensate in the vent

pipe, resulting in potential boiler

shutdown. In extremely cold cli-

mates, install an insulated chase

around the vent piping, particu-

larly when using longer lengths. The

chase must allow for inspection of

the vent pipe, and insulation must

be protected from water.

-ULTIPLEVENTAIRTERMINATIONS

1. When terminating multiple GV90+ boilers,

terminate each vent/air connection as de-

scribed in this manual.

All vent pipes and air inlets must

terminate at the same height to

avoid possibility of severe personal

injury, death or substantial property

damage.

2. Place wall penetrations to obtain minimum

clearances shown in Figure 48, page 40 for

U. S. installations. For Canadian installations,

provide clearances required by CSA B149.1

Natural Gas and Propane Installation Code

or B149.2 Installation Code.

3. The air inlet of a GV90+ boiler is part of a

direct vent connection. It is not classified as a

forced air intake with regard to spacing from

adjacent boiler vents.

4. Combustion air (NOT vent piping) can be

manifolded as shown in Figure 37, page 31.

&IGURE ).34!,,!4)/.3%15%.#% — Separate pipes sidewall

3TEP Read and follow all instructions in this manual. $/./4PROCEEDWITH

VENTAIRINSTALLATIONUNTILYOUHAVEREADPAGETHROUGHPAGE

3TEP Install the boiler in a location that allows proper routing of all vent and air

piping to the selected sidewall location.

3TEP Make sure the selected sidewall termination location complies with Fig-

ure 41, page 35. (Multiple boiler sidewall plates must also comply with

Figure 48, page 40.)

3TEP Use only the vent materials listed in Figure 40, page 33. Provide pipe adapt-

ers where required. Vent piping and air piping lengths must not exceed the

values shown in Figure 39, page 32.

3TEP Prepare the sidewall penetrations and secure the sidewall plates as instructed

in this section. See “Prepare wall penetrations” on page 40.

3TEP The air piping must terminate in a DOWNTURNEDELBOW as shown above.

The vent piping must terminate in an ELBOWPOINTEDOUTWARDORAWAY

FROMTHEAIRINLET as shown above. See illustration above.

3TEP Install vent and air piping between the boiler and the sidewall openings.

Slope horizontal piping downward toward the boiler at least 1/4 inch per

foot. See page 48 for general guidelines.

3TEP Install pipe supports every 5 feet on both the horizontal and vertical runs.

Install a hanger support within 6 inches of any upturn in the piping.

3TEP Attach the vent termination exterior piping: Use either of the configurations

shown above, as needed to ensure clearance above grade or snow line. Keep

vents/air intake area clear of accumulating snow.

3TEP The vent and air pipes may run up as high as 4 feet with no enclosure.

The vent and air pipes must be secured with braces, and all clearances and

lengths must be maintained. Space braces no further than 24 inches apart.

3TEP External venting greater than 4 feet requires an insulated enclosure around

the vent and air pipes. The vent and air terminations must exit through

the enclosure as shown in the illustration above, maintaining all required

clearances.

GV90+ Series 2 GAS-FIRED WATER BOILER — Boiler Manual

DIRECT VENT — 3IDEWALLWITHSEPARATEPIPES

Loading...

Loading...