Part number 550-142-903/1016

55

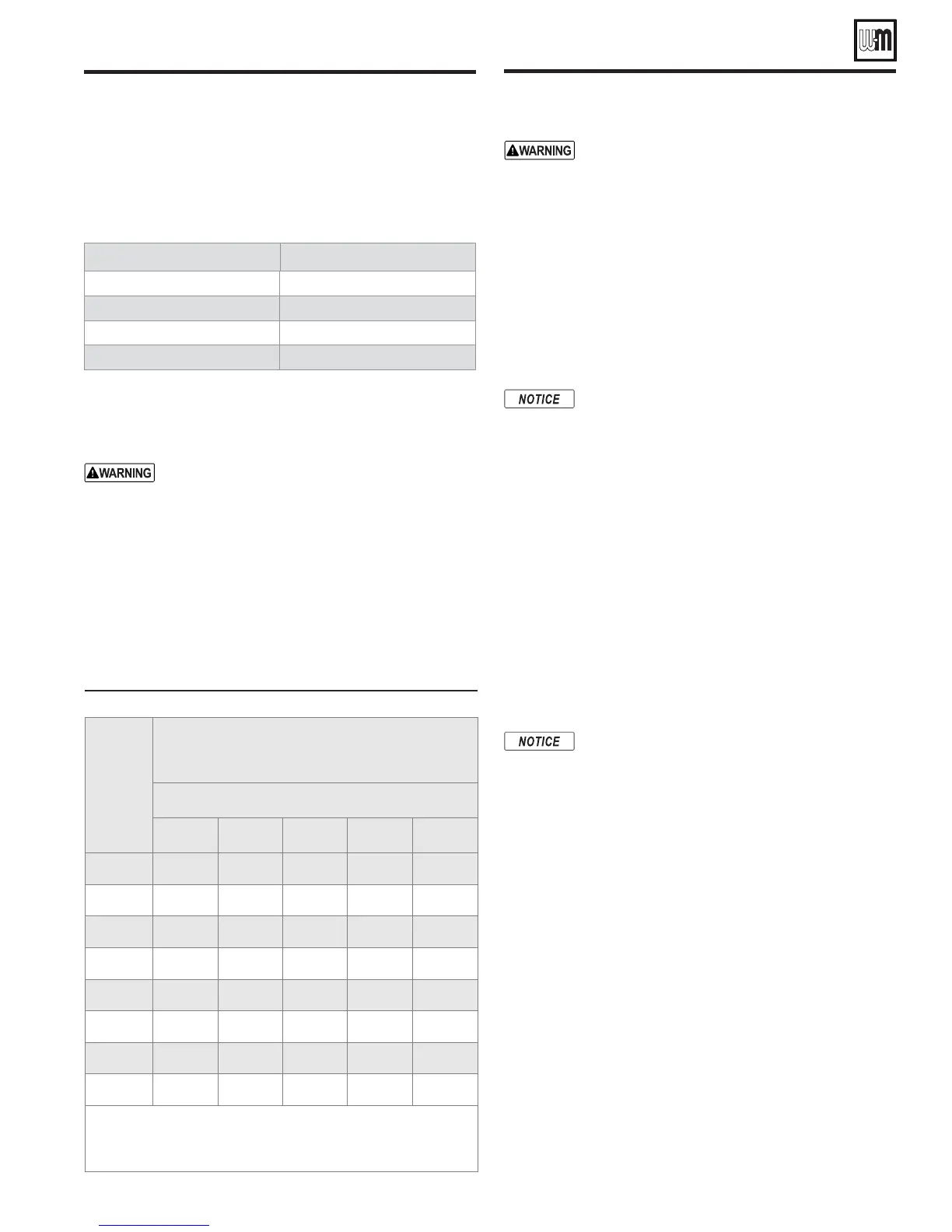

&IGUREPipe capacity for 0.60 specific gravity natural gas

'ASPIPE

LENGTH

FEET

#APACITYINCUBICFEETOFGASPERHOUR

.ATURALGASONLYWITHSPECIlCGRAVITYOF

"ASEDONPRESSUREDROPOFvWC

Gas pipe diameter —

v Ðv v v v

10

132 278 520 1050 1600

20

92 190 350 730 1100

30

73 152 285 590 860

40

63 130 245 500 760

50

56 115 215 440 670

75

45 93 175 360 545

100

38 79 150 305 460

150

31 64 120 250 380

&ORADDITIONALGASPIPESIZINGINFORMATIONREFERTO!.3):.&0!

54 (or Natural Gas and Propane Installation Code,

B149.1 or B149.2 for

Canadian installations).

For your safety, turn off electrical power supply at

service entrance panel before making any electrical

connections to avoid possible electric shock hazard.

Failure to do so can cause severe personal injury or

death.

)NSTALLATIONMUSTCOMPLYWITH

National Electrical Code and any other national, state, provincial

or local codes or regulations. In Canada, CSA C22.1 Canadian

Electrical Code Part 1, and any local codes. Boiler must be elec-

trically grounded as required by National Electrical Code ANSI/

NFPA 70 - latest edition.

Wiring must be N.E.C. Class 1. Boiler must be elec-

trically grounded as required by National Electrical

Code ANSI/NFPA 70 - latest edition.

To replace wiring, order complete harness assem-

blies from Weil-McLain. If any original wiring as

supplied with boiler must be replaced, and a har-

ness is not immediately available, use only type

105°C wire or equivalent. Use this wiring only as a

temporary repair. Obtain a complete harness from

Weil-McLain.

Wiring connections

0OWERWIRING

Connect 120 VAC power wiring as shown in . The junction box

is located on the inside left jacket panel.

Watch the polarity of the circuit when connect-

ing the 120 VAC power wiring. If the polarity is

switched, the integrated boiler control will lockout.

The IBC will flash the POWER light to indicate

this problem. See the troubleshooting information

beginning on page 76.

!DDITIONALLIMITCONTROLS

Wire additional limit controls (if used) as shown in Fig-

ure 67, page 56.

Thermostat(s)

Install thermostats on inside walls, away from influences of

drafts, hot or cold water pipes, lighting fixtures, television, sun

rays, or fireplaces.

Follow instructions with thermostat. If it has a heat anticipator,

set heat anticipator in thermostat to match power requirements

of equipment connected to it (ignition control and gas valve, zone

valve contacts, etc.). Wiring diagram on boiler gives setting for

standard equipment (ignition control and gas valve).

GV90+ Series 2 GAS-FIRED WATER BOILER — Boiler Manual

Natural Gas

1. Refer to Figure 65 for pipe length and diameter. Size gas

supply piping for total flow to all connected appliances. For

each GV90+ boiler, provide for the following gas flow (cfh =

cubic feet per hour):

"OILERMODEL #&(NATURALGAS

GV90+3 70

GV90+4 105

GV90+5 140

GV90+6 175

2. Inlet pressure required at gas valve inlet:

s maximum 14” w.c.

s minimum 3.5” w.c.

Install 100% lockup gas pressure regulator in sup-

ply line if inlet pressure exceeds 14” water column.

Adjust for 14” w.c. maximum.

Propane Gas

1. Contact gas supplier to size pipes, tanks and 100% lockup

gas pressure regulator.

2. Adjust propane supply regulator provided by gas supplier for

14” w.c. maximum pressure.

3. Inlet pressure required at gas valve inlet:

s maximum 14” w.c.

s minimum 3.5” w.c.

Gas piping (continued)

Wiring

Loading...

Loading...