Part number 550-142-903/1016

71

Inspect temperature mixing system

1. Carefully check the TEMPERATUREof the SYSTEMRETURNPIP

ING

as it passes through the boiler jacket and on the RETURN

PIPEINSIDETHEBOILERJACKET

just before it enters the boiler

sections. You may do this with a surface pyrometer or by

lightly touching the piping with your fingers.

To avoid potential of severe burn — $ONOTREST

HANDSONORGRASPPIPES

. Use a light touch only.

Return piping may heat up quickly.

2. The temperature of the water entering the system should

quickly heat up to about

&, being considerably hotter

than the return water from the system.

3. This is accomplished with the

TWOINTERNALBOILERCIRCULA

TORS

. The Bypass circulator (page 2, item 7) takes hot water

from the boiler supply outlet and blends it with return water.

The System circulator (page 2, item

6) slows down to aid in

raising the return temperature entering the sections.

4. If the

TEMPERATUREMIXINGSYSTEM does not work correctly,

check the two circulators to be sure they are flowing water. If

the circulators are operating normally but the temperature

mixing system does not maintain water at the entrance to the

boiler sections at 140°F, you may need to replace the boiler

IBC or water temperature sensor (page 2, items

1 and 8).

Inspect additional controls and cutoffs

1. Inspect and test the boiler additional controls. Verify opera-

tion by turning control set point below boiler temperature.

Boiler should cycle off. Return dial to original setting.

2. Inspect and test additional limit controls or low water cut-

offs installed on system. Follow the device manufacturer's

instructions.

Inspect gauges

1. Boiler pressure/temperature gauge — Inspect gauge and check

whether readings are reasonable. Replace if any signs of leakage

from case or improper readings.

2. System gauges (if installed) — Inspect and check readings of

other gauges in system.

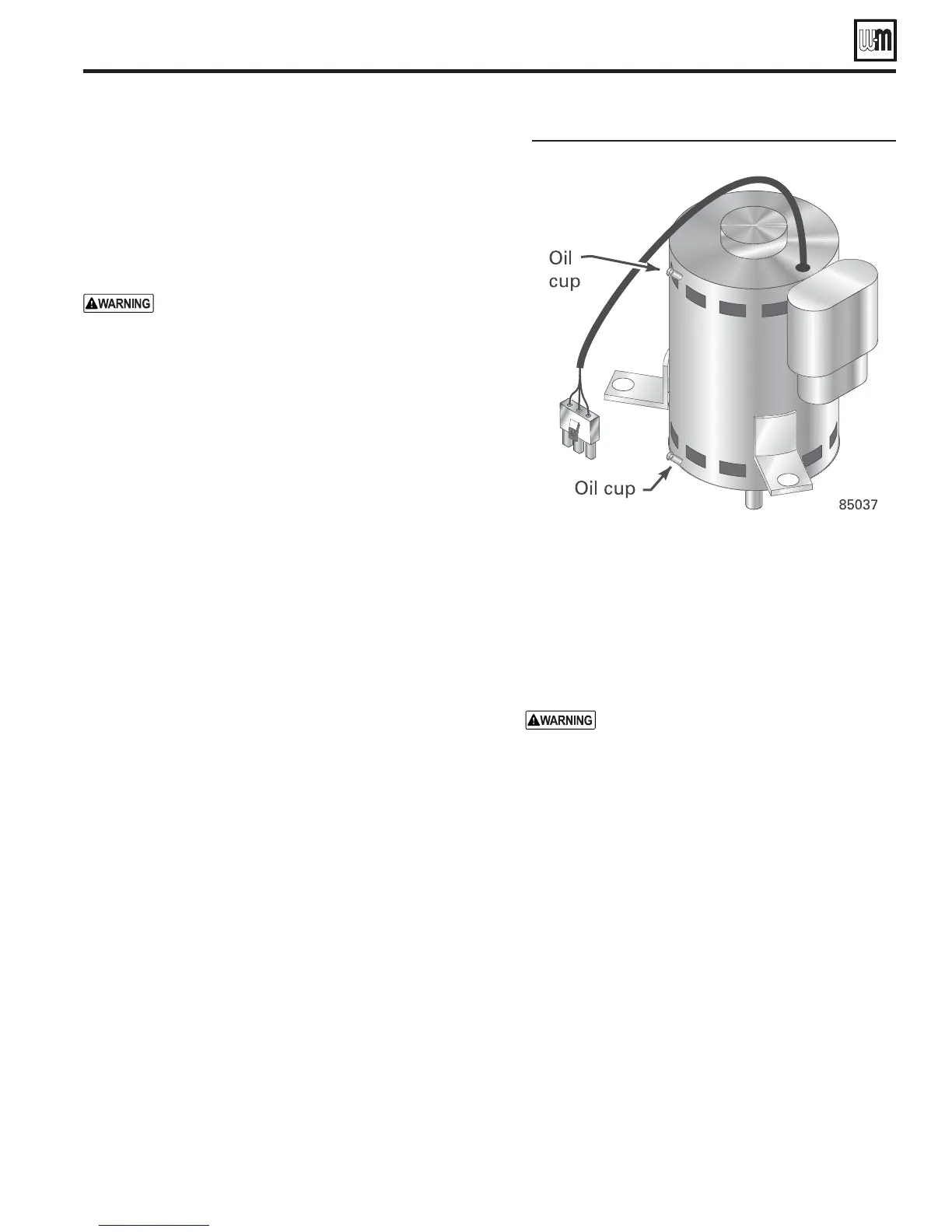

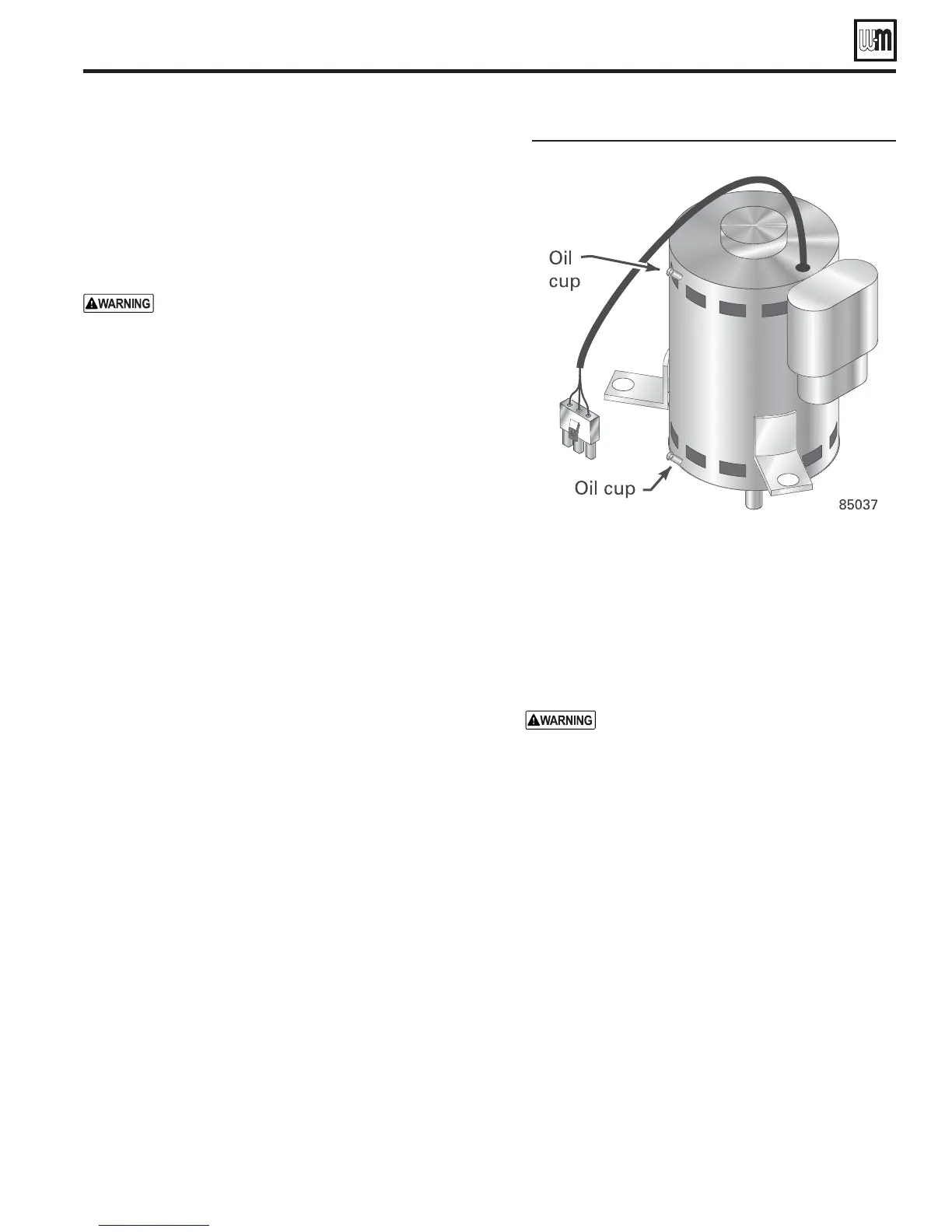

&IGURE Blower motor

Inspect blower motor

1. Oil blower motor only if required, some GV90+

boilers may have an alternate sealed bearing blower

motor, (No oiling required).

2. See Figure 79. For blower motors that do require oiling,

with boiler power OFF, place a few drops of Anderol 465

in each of the two oil cups.

Use only !NDEROL to lubricate the

blower motor. Do not use universal house-

hold oils. Motor could be damaged, result-

ing in possible severe property damage.

Not required on

Inspect oiled-bearing circulators

1. Both of the circulators installed in the boiler are water-

lubricated. No oiling is required.

2. Check other circulators in the system. Oil any circulators

requiring oil, following circulator manufacturer’s instruc-

tions. Over-oiling will damage the circulator.

Inspect Temperature sensor

1. The temperature sensor may accumulate deposits on the

probe surface. Annual inspection and cleaning of the

probe will improve boiler performance.

Disconnect power, unplug harness from sensor.

a. Drain boiler water to a level below the sensor.

b. Remove sensor from boiler using a deep well socket.

c. Wipe any built up contaminates from probe and

insulator surfaces.

d. Reinstall using a deep well socket sensor into the

boiler. Do not overtighten.

GV90+ Series 2 GAS-FIRED WATER BOILER — Boiler Manual

Annual start-up (continued)

Loading...

Loading...