Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-2 September 2014 Page 10

Noise Suppression at Source

If possible, eliminate mechanical contact relays and replace with solid-state relays.

Noise-generating devices such as Ignition transformers, arc welders, motor drives, relays

and solenoids should be mounted in a separate enclosure. If this is not possible, separate

them from the instrumentation, by the largest distance possible.

Many manufacturers of relays, contactors etc supply 'surge suppressors' to reduce noise at

its source. For those devices that do not have surge suppressors supplied, Resistance-

Capacitance (RC) networks and/or Metal Oxide Varistors (MOV) may be added.

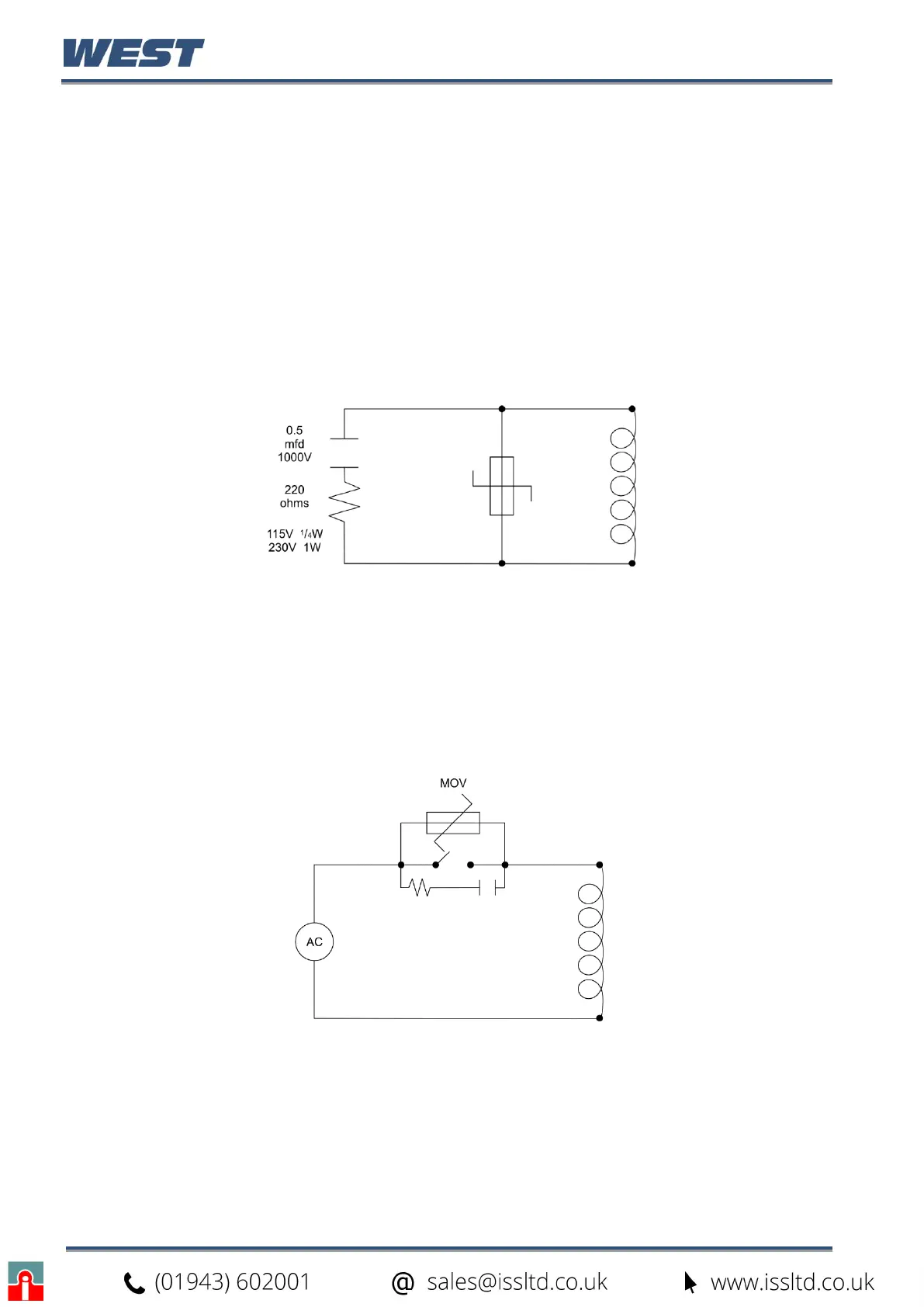

Inductive coils:- MOVs are recommended for transient suppression in inductive coils.

Connect as close as possible, in parallel to the coil. Additional protection may be provided by

adding an RC network across the MOV.

Figure 5. Transient suppression with inductive coils

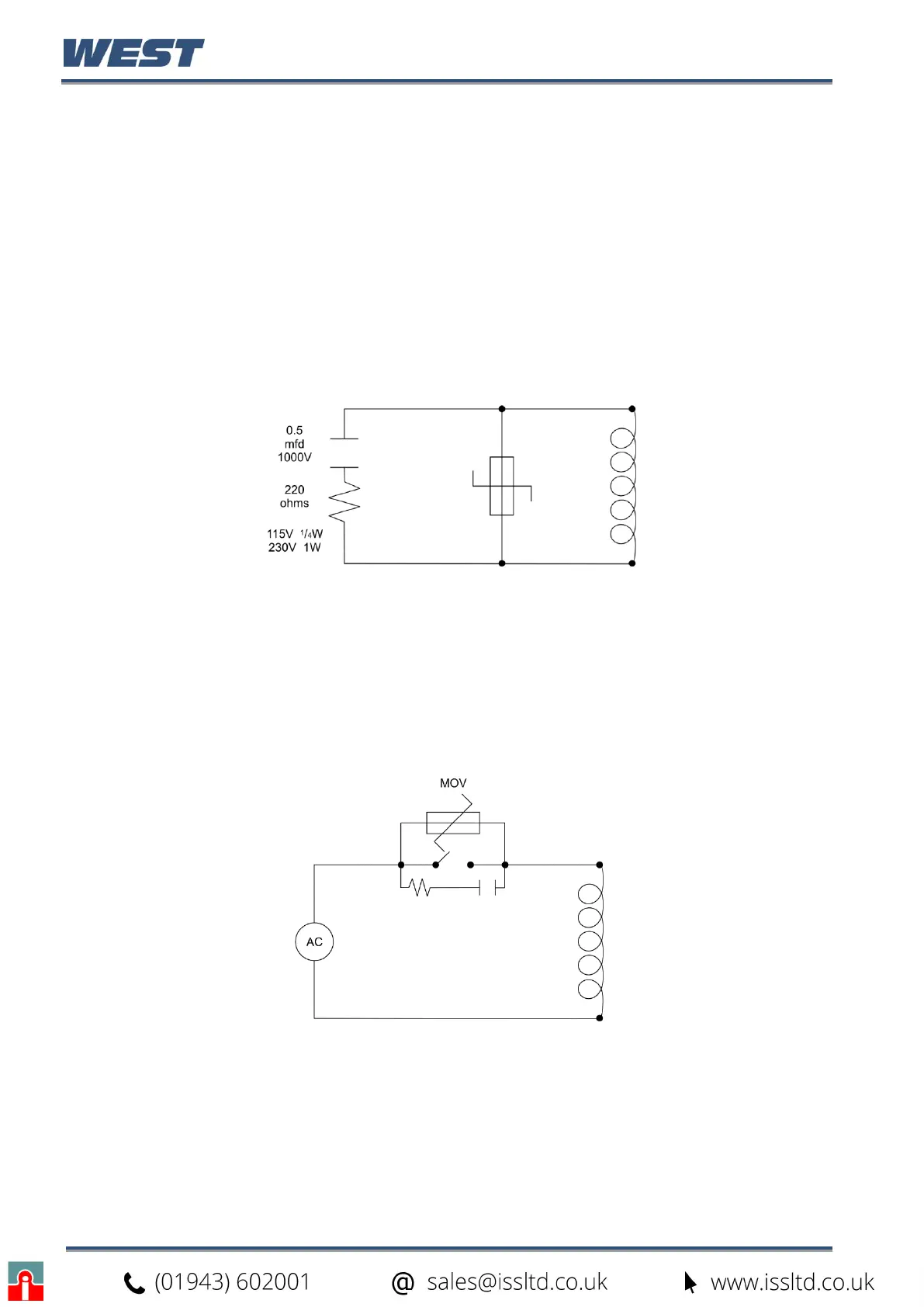

Contacts:- Arcing may occur across contacts when they open and close. This results in

electrical noise as well as damage to the contacts. Connecting a properly sized RC network

can eliminate this arc.

For circuits up to 3 amps, a combination of a 47 ohm resistor and 0.1 microfarad capacitor

(1000 volts) is recommended. For circuits from 3 to 5 amps, connect two of these in parallel.

Figure 6. Contact noise suppression

Loading...

Loading...