Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-2 September 2014 Page 71

Two Point Calibration

This method is used where an error is not constant across the range.

Separate offsets are applied at two points in the range to eliminate both “zero” and “span”

errors. To use:

1. Measure and record the error at a low point in the process.

2. Measure and record the error at a high point in the process.

3. Go to the first two point input calibration screen.

a. Enter the desired low point value as the Calibration Low PV value.

b. Enter an equal, but opposite value to the observed error as the Calibration Low

Offset to correct the error at the low point.

4. Go to the second two point input calibration screen.

a. Enter the desired high point as the Calibration High PV value.

b. Enter an equal, but opposite value to the observed error as the Calibration High

Offset to correct the error at the high point.

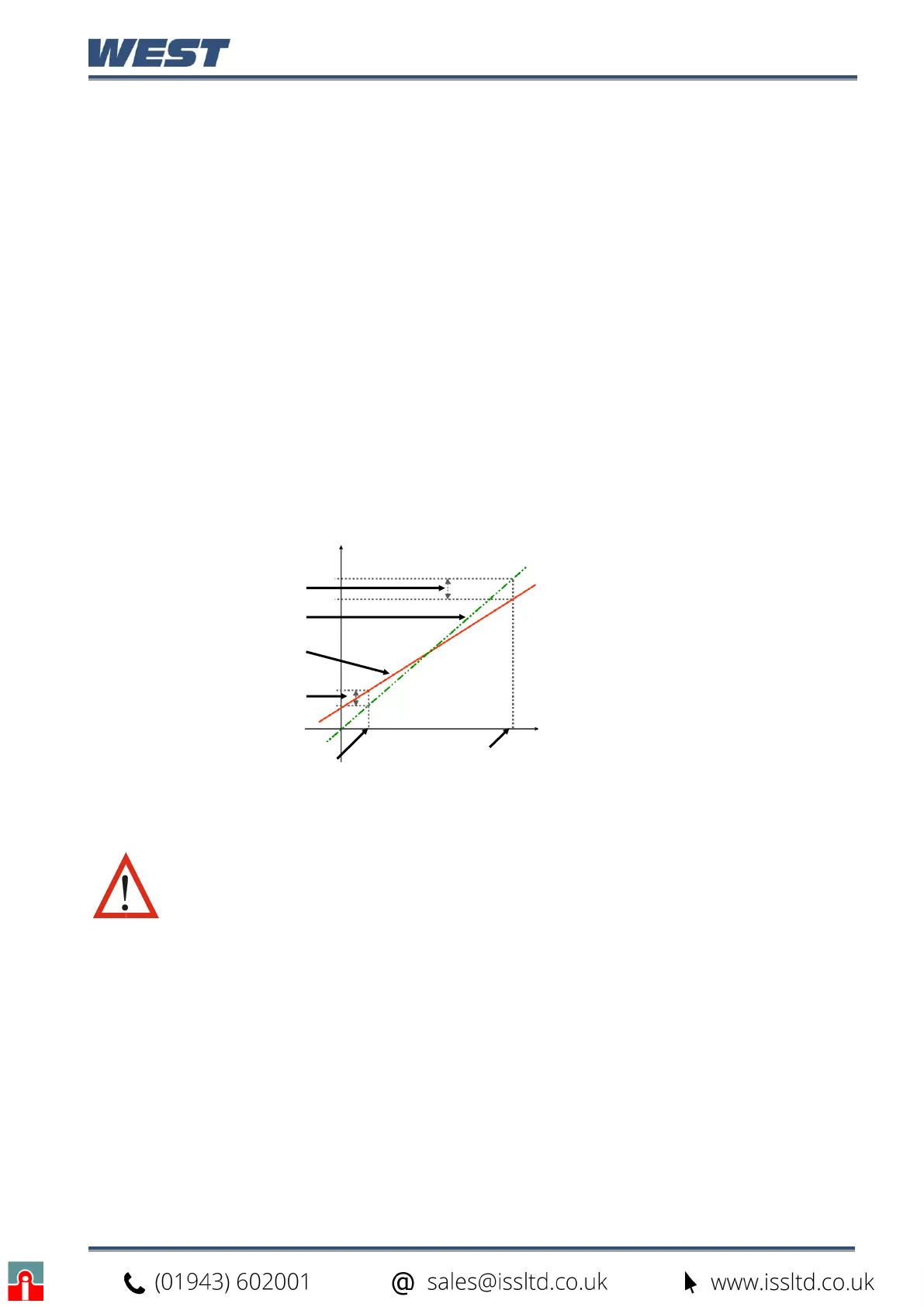

This example shows a positive Low

Offset and a negative High Offset. For

example:

If the process displays a low end error

where +0.5 displays as 0.0, an offset

of +0.5 corrects the value to +0.5

A high end value of 100.0 with a -1.7

offset would read 98.3.

There is a linear relationship between

these two calibration points.

Figure 45. Two Point Calibration

CAUTION: Choose values as near as possible to the bottom and top of

your usable span to achieve maximum calibration accuracy. The effect of

any error can grow at values beyond the chosen calibration points.

New Displayed Value

Calibration High

Process Value

Process Value

Loading...

Loading...