PISTONS

AND

CONNECTING

RODS

PISTON

PIN

INSPECTION

Reinsert the piston pin into the piston hole with your thumb.

You

should feel a slight resistance,

if

the bore is misaligned

the pin will click or bind as it enters.

Try the pin from both

sides. Replace the piston

if

the pin can be too easily inserted

or if there

is

excessive play.

NOTE:

The

piston

pin and piston

are

replaced

as

an

assembly.

Measure the outside diameter

of

the piston pin.

PISTON

PIN

0.0.0.6300

-

0.6302io

(16.001

-16.007mm)

Pistons

Check the piston surfaces for wear, seizure, cracks and

streaking.

If

any damage is evident, replace the piston.

Inspect the oil return hole in the oil ring groove and the oil

hole in the piston boss. Clean the piston

if

these are clogged.

Check the piston pin hole for signs

of

seizure or damage.

Replace the piston

if

damage is

evident

Measure the piston

diameter at

90° (perpendicular) to the pin bore axis.

PISTON

0.0.2.5579

-

2.5591io

(64.97

-

65.00mm)

If

the piston diameter is less then the standard replace

the piston.

NOTE:

The

piston and piston pin

are

replaced

as

an

assembly.

Piston

Rings

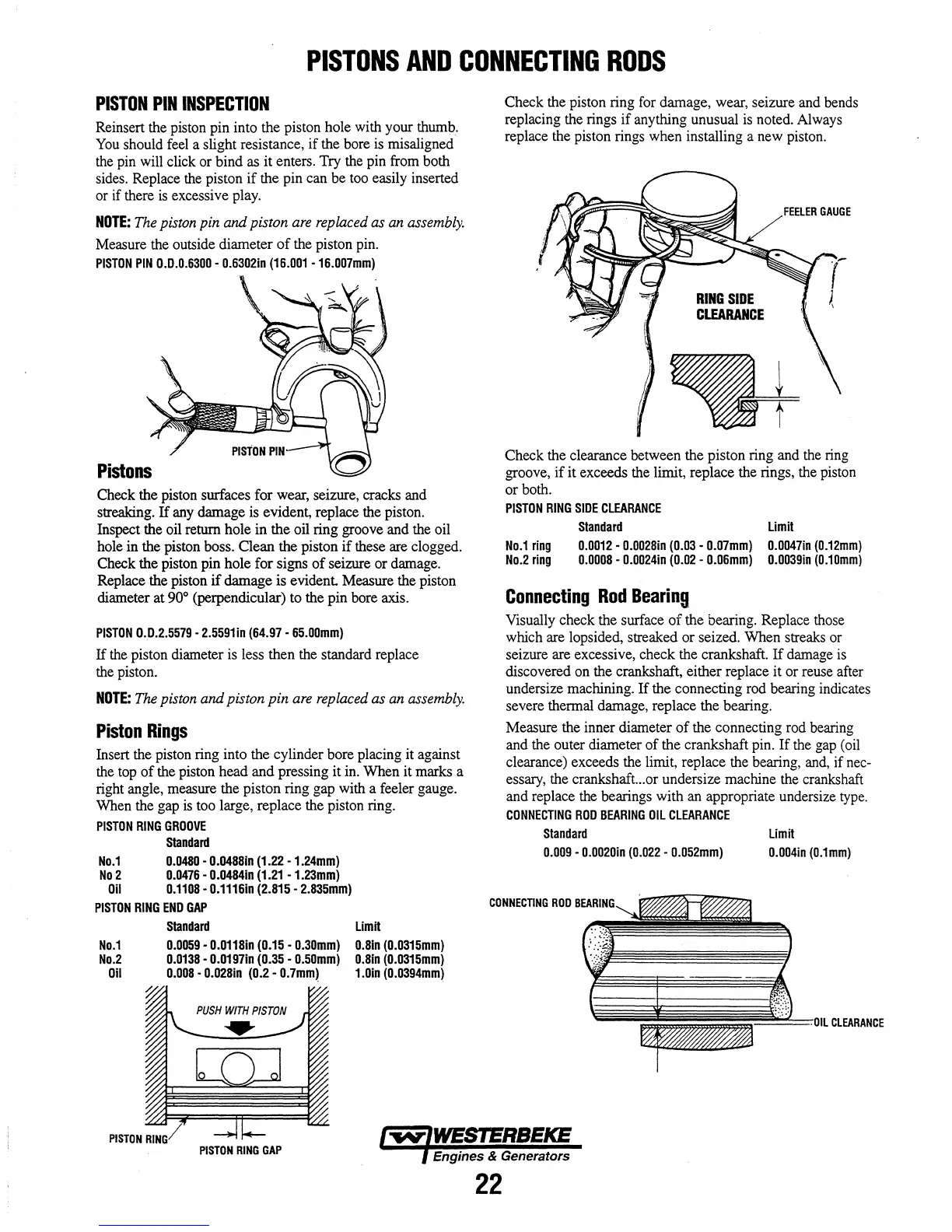

Insert the piston ring into the cylinder bore placing it against

the top

of

the piston head and pressing it in. When it marks a

right angle, measure the piston ring gap with a feeler gauge.

When the gap is too large, replace the piston ring.

PISTON

RING

GROOVE

staodard

No.1

0.0480

-

0.048810

(1.22

-

1.24mm)

No

2

0.0476

-

O.0484io

(1.21

-1.23mm)

Oil

0.1108

-

0.1116io

(2.815

-

2.835mm)

PISTON

RING

END

GAP

No.1

No.2

Oil

PISTON

staodard

0.0059

-

0.0118io

(0.15

-

0.30mm)

0.0138

-

0.0197io

(0.35

-

0.50mm)

0.008

-

0.028io

(0.2

-

0.7mm)

Limit

0.810

(0.0315mm)

0.8io

(0.0315mm)

1.0io

(0.0394mm)

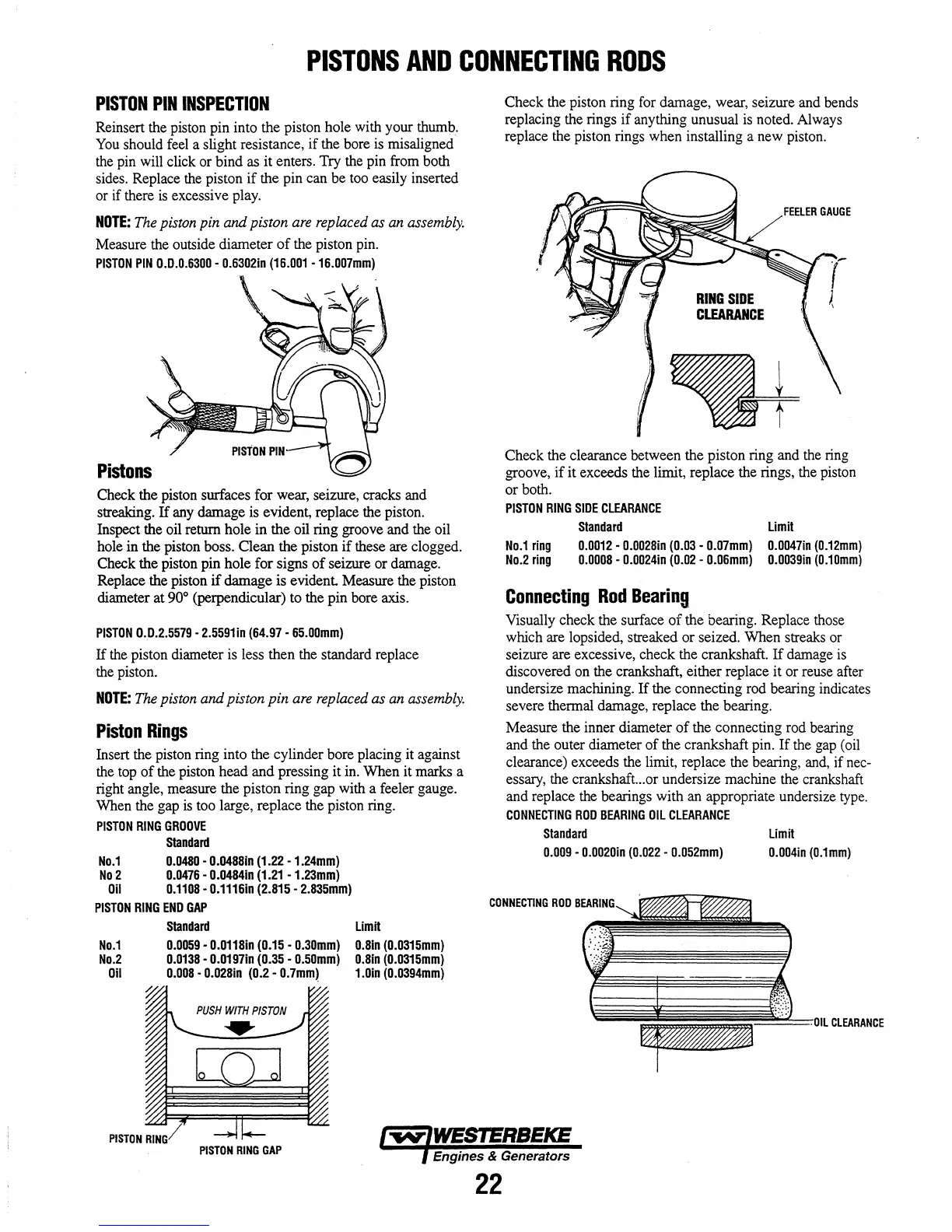

Check the piston ring for damage, wear, seizure and bends

replacing the rings

if

anything unusual is noted. Always

replace the piston rings when installing a new piston.

RING

SIDE

ClEARANCE

FEELER

GAUG

E

Check the clearance between the piston ring and the ring

groove,

if

it exceeds the limit, replace the rings, the piston

or

both.

PISTON

RING

SIDE

CLEARANCE

Staodard

Limit

No.1

riog

No.2

riog

0.0012

-

0.0028io

(0.03

-

0.07mm)

0.0047io

(0.12mm)

0.0008

-

0.0024io

(0.02

-

0.06mm)

0.0039io

(0.10mm)

Connecting

Rod

Bearing

Visually check the surface

of

the bearing. Replace those

which are lopsided, streaked

or

seized. When streaks or

seizure are excessive, check the crankshaft.

If

damage is

discovered on the crankshaft, either replace

it

or reuse after

undersize machining.

If

the connecting rod bearing indicates

severe thermal damage, replace the bearing.

Measure the inner diameter

of

the connecting rod bearing

and the outer diameter

of

the crankshaft pin.

If

the gap (oil

clearance) exceeds the limit, replace the bearing, and,

if

nec-

essary, the crankshaft...or undersize machine the crankshaft

and replace the bearings with an appropriate undersize type.

CONNECTING

ROD

BEARING

OIL

CLEARANCE

Staodard

Limit

0.009

-

0.0020io

(0.022

-

0.052mm)

0.004io

(0.1mm)

CONNECTING

ROD

Y~'''''''''

.....

PISTON

RING

GAP

Engines & Generators

22

Loading...

Loading...