PISTONS

AND

CONNECTING

RODS

NOTE:

See

Crankshaft/Bearing section for measuring

the

oil

clearance

with

a Plastigauge.

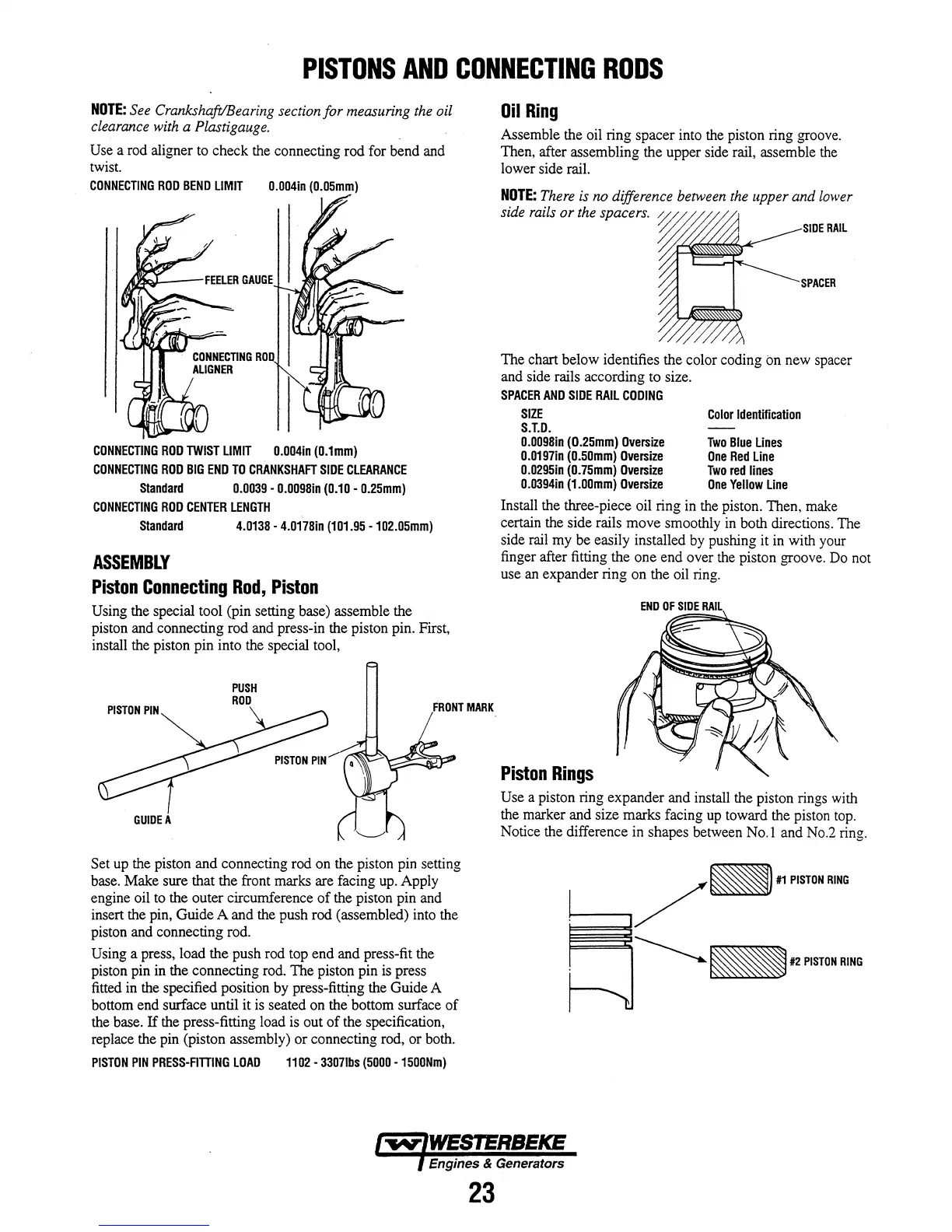

Use a rod aligner to check the connecting

rod

for bend and

twist.

CONNECTING

ROD

BEND

LIMIT

0.004in

(O.OSmm)

CONNECTING

ROD

TWIST

LIMIT

0.004in

(0.1mm)

CONNECTING

ROD

BIG

END

TO

CRANKSHAFT

SIDE

CLEARANCE

Standard

0.0039

-

0.0098in

(0.10

-

0.2Smm)

CONNECTING

ROD

CENTER

LENGTH

Standard

4.0138

-

4.0178in

(101.9S

-102.0Smm)

ASSEMBLY

Piston

Connecting

Rod,

Piston

Using the special tool (pin setting base) assemble the

piston and connecting

rod

and press-in the piston pin. First,

install the piston pin into the special tool,

GUIDE

A

PUSH

ROD

FRONT

MARK

Set up the piston

and

connecting rod on the piston pin setting

base. Make sure that the front marks are facing up. Apply

engine oil to the outer circumference

of

the piston pin and

insert the pin, Guide A and the push rod (assembled) into the

piston and connecting rod.

Using a press, load the push rod top

end

and press-fit the

piston pin in the connecting rod. The piston pin is press

fitted in the specified position

by

press-fini:ng the Guide A

bottom end surface until it is seated on the bottom surface

of

the base.

If

the press-fitting load is out

of

the specification,

replace the pin (piston assembly)

or

connecting rod, or both.

PISTON

PIN

PRESS-FITTING

LOAD

1102

-

33071bs

(SOOO

-1S00Nm)

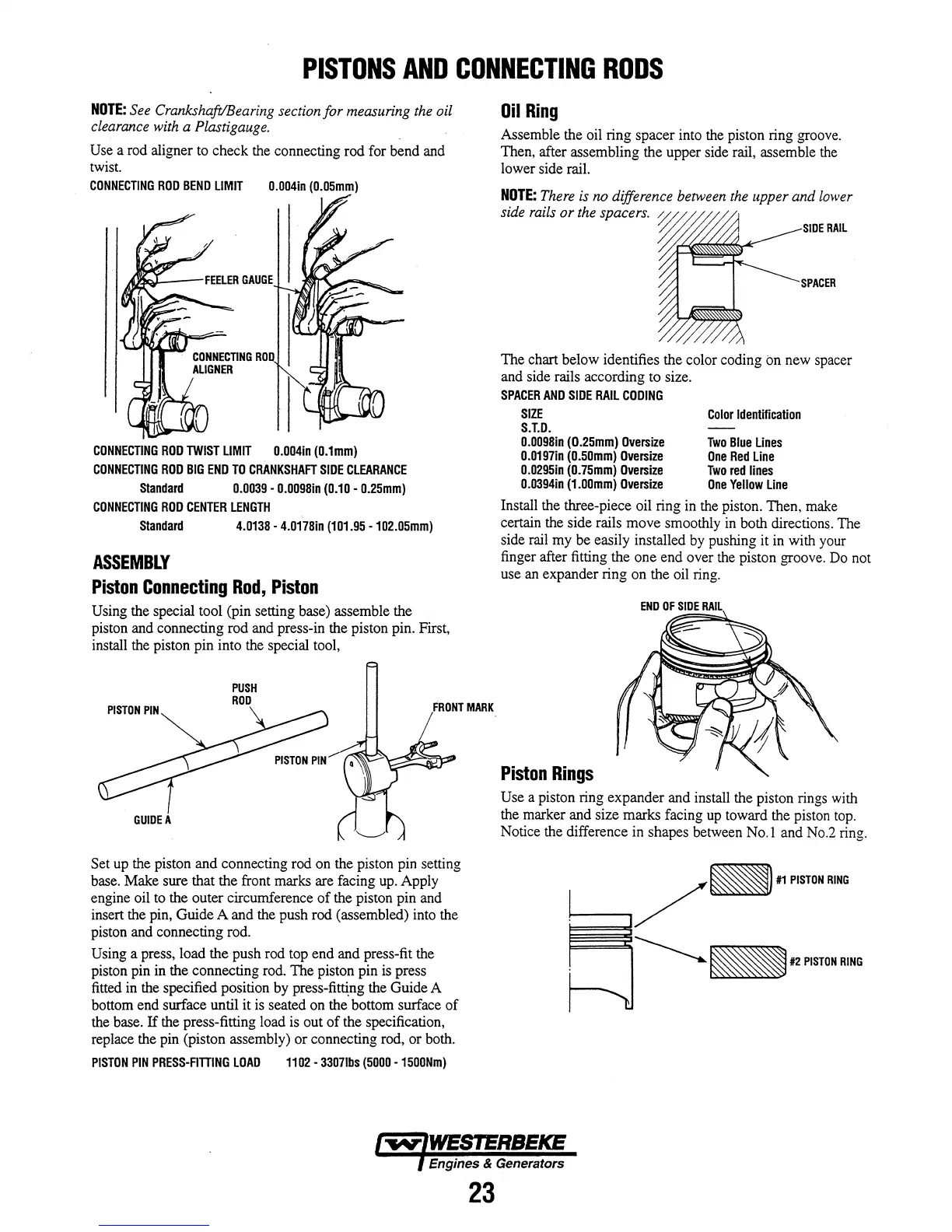

Oil

Ring

Assemble the oil ring spacer into the piston ring groove.

Then, after assembling the upper side rail, assemble the

lower side rail.

NOTE:

There

is

no

difference between

the

upper and

lower

side

rails

or

the

spacers.

W~-j/

//,

m

SIDE

RAIL

~~,......-

'-----~

SPACER

The chart below identifies the color coding on new spacer

and side rails according to size.

SPACER

AND

SIDE

RAIL

CODING

SIZE

Color

Identification

S.T.D.

0.0098in

(O.2Smm)

Oversize

Two

Blue

Lines

0.0197in

(O.SOmm)

Oversize

One

Red

Line

0.029Sin

(0.7Smm)

Oversize

Two

red

lines

0.D394in

(1.00mm)

Oversize

One

Yellow

Line

Install the three-piece oil ring in the piston. Then, make

certain the side rails

move

smoothly in both directions. The

side rail

my

be easily installed by pushing it in with your

finger after fitting the one

end

over the piston groove. Do not

use an expander ring on the oil ring.

END

OF

SIDE

RAIL

Piston

Rings

Use a piston ring expander and install the piston rings with

the marker and size marks facing up toward the piston top.

Notice the difference in shapes between No.1 and No.2 ring.

1--

__

.,/-"

PlSTDO

ROG

~~#2PISTONRING

Engines & Generators

23

Loading...

Loading...