STARTING THE APPLIANCE

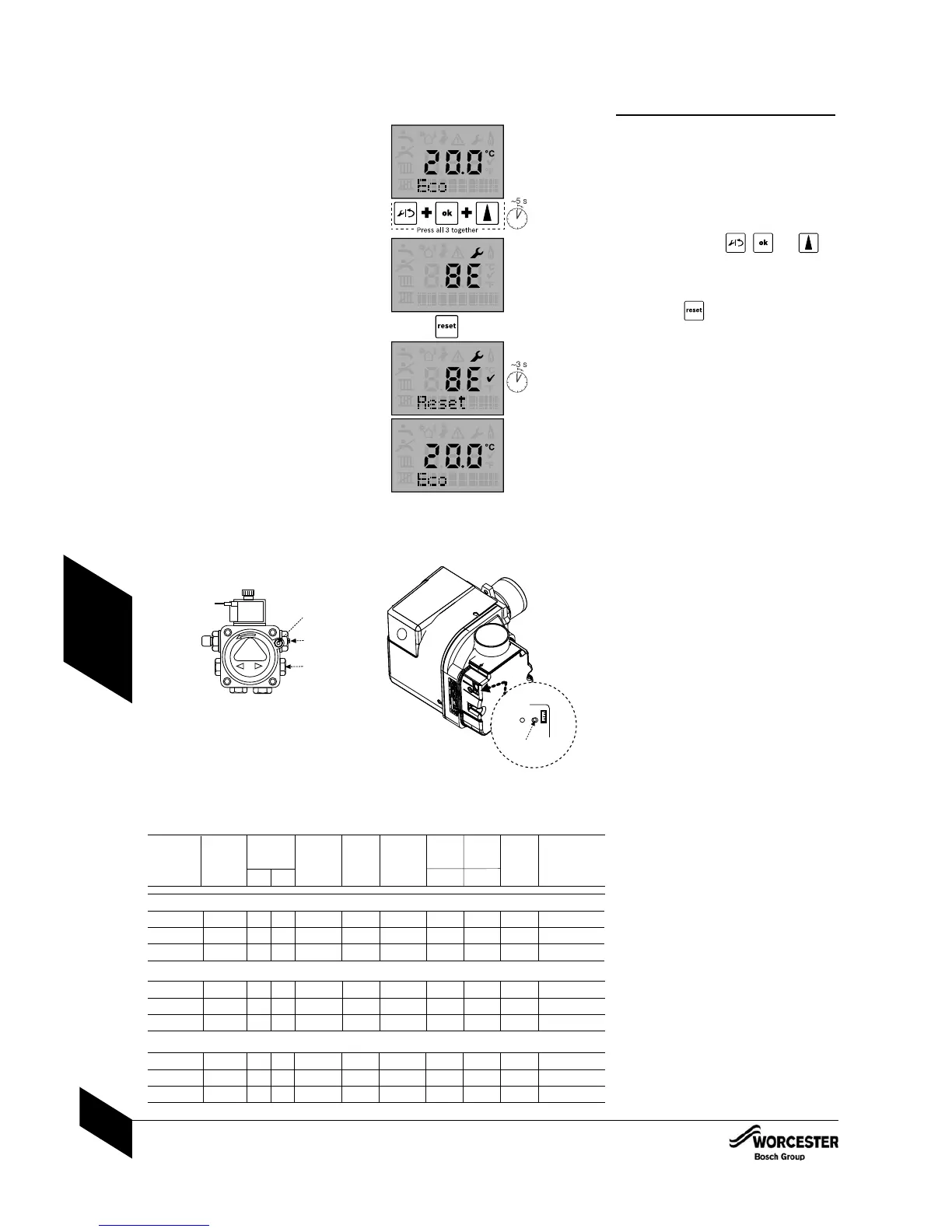

Reset to factory settings:

To reset any or all changes made in Menu 2

back to the factory default setting:

NOTE: Any changes made to Menu 1 are not

reset by these actions.

14 Press and hold the and

buttons for at least 5 seconds. The screen

will then display code BE with the spanner

symbol.

24 Press the button and ‘reset’ will be

displayed with the tick symbol for 3

seconds. After 3 seconds the display will

revert to the normal operation screen.

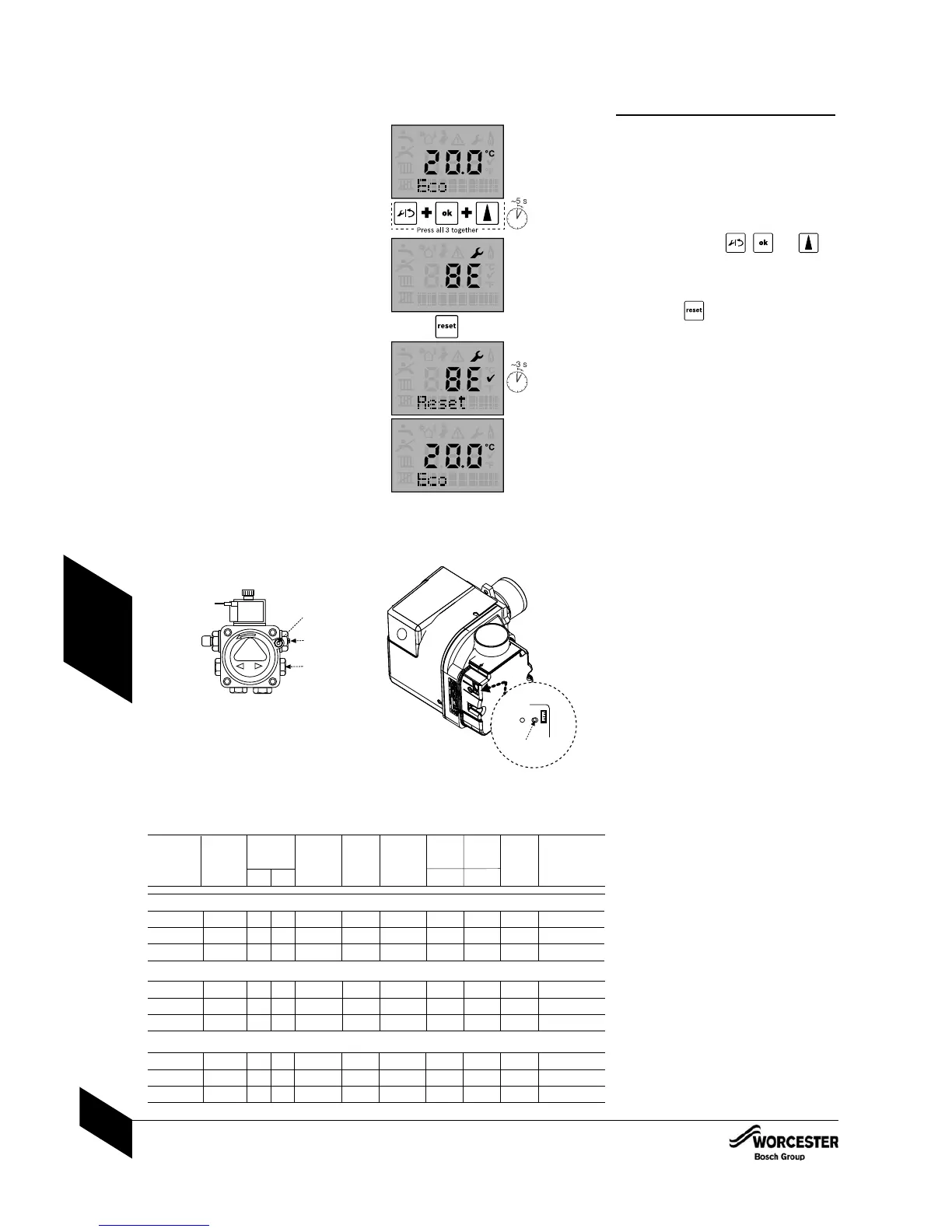

Finish pre-commissioning boiler checks:

4Check the CO

2

levels and adjust the air

shutter (L) setting according to the table

opposite.

4Check the flue gas temperature is close to

the values shown in the table.

If the flue gas temperature is too high and the

baffles are correctly fitted, then reduce the oil

pump pressure (B) 5-10p.s.i. to compensate

for nozzle variations.

4Turn off the electrical supply.

4Isolate the oil supply to the burner.

4Remove the oil pressure gauge.

4Refit the blanking plug (A).

4Check and rectify any oil leaks.

34Switch on the oil supply.

4Switch on the electrical supply.

4Restart the boiler and run for 5 minutes.

4Recheck the CO

2

levels and if required,

adjust the air shutter setting (D) to obtain

the correct CO

2

level.

4Refit the sample point cap (hand tighten

only, do not over tighten) and refit the burner

cover.

Loading...

Loading...