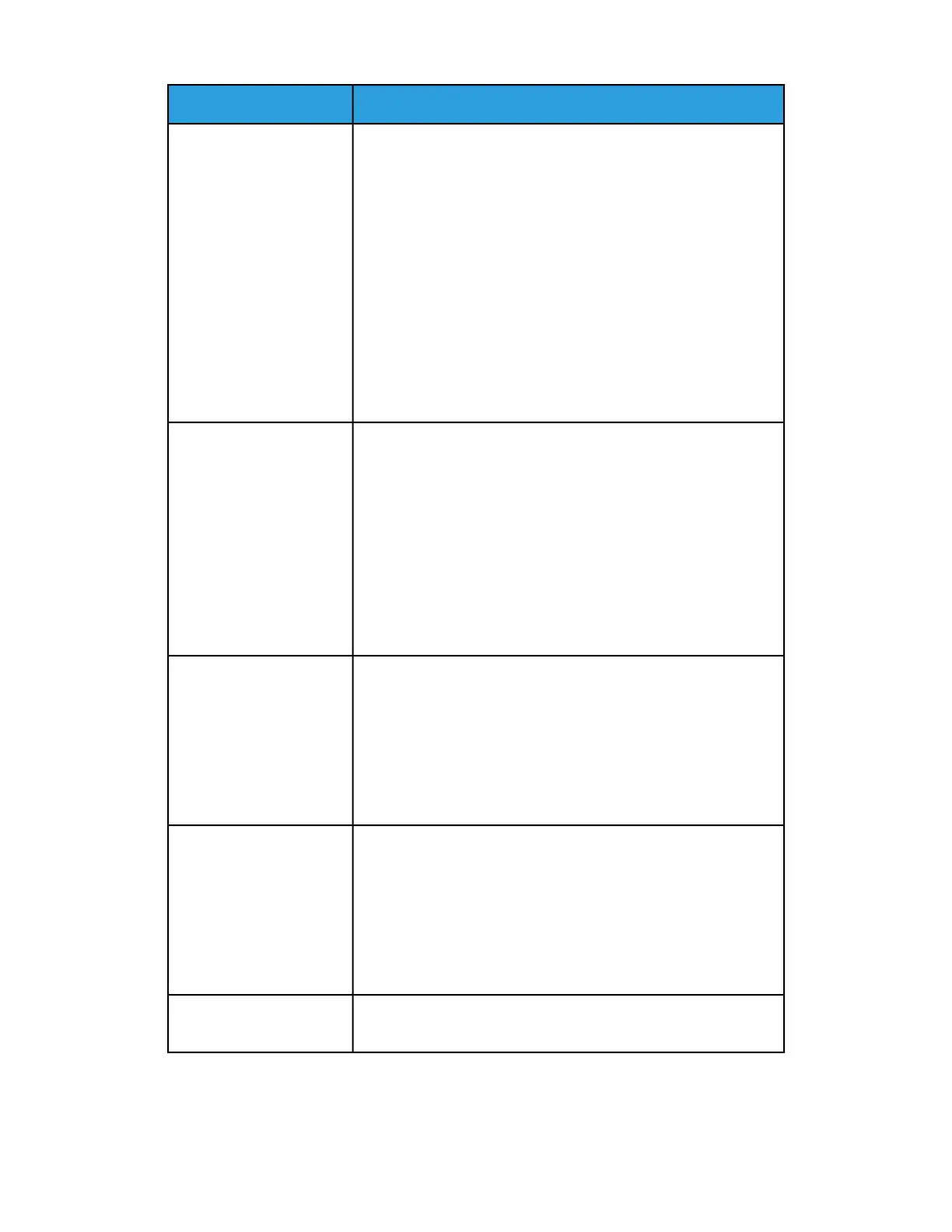

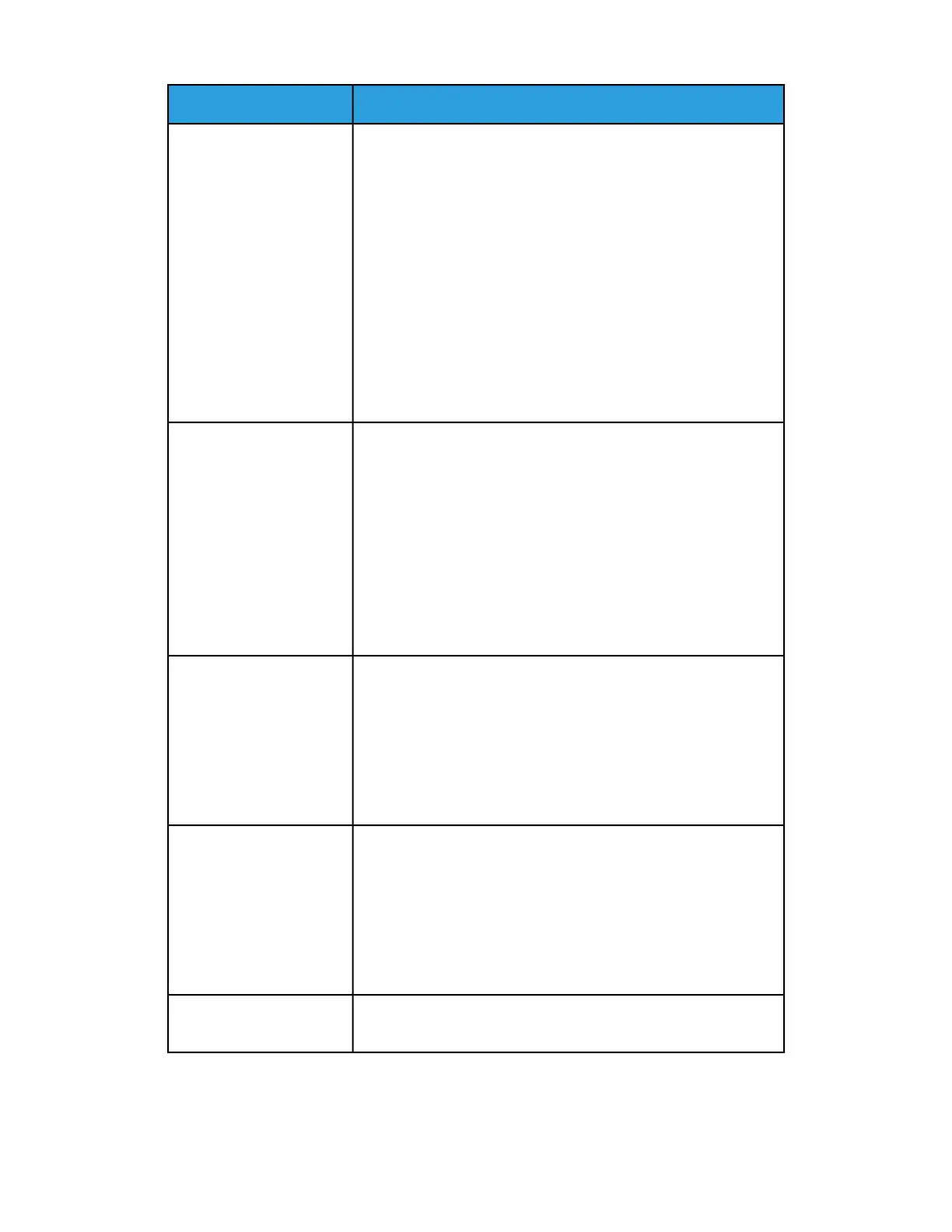

Suggested SolutionsProblem

Random white or dark spots

The prints show random

spots, but they do not re-

peat at regular intervals.

• Ensure that the media used is approved, within press specifica-

tions and is clean.

• Check that the press is within environmental specifications

(humidity levels).

• Load a new ream of paper, different media.

• Run the Clean Toner procedure; for specific instructions, refer

to the System Administration Guide, System Settings chapter

(Common Service Settings, Maintenance section).

• Check for Drum failure or damage. Acquireyourmeasuringtool

from the Nationalization Kit and check the frequency of the

spot intervals. If spots occur every 147 mm on the prints, run

the Halftone Test Pattern to determine which color drum is af-

fected. Replace or swap the Drum; refer to Drum Cartridge.

Acquire the measuring tool from the Nationalization Kit. Check

the frequency of the defect interval.

Repeating Defect at regular

intervals

The prints show any defect

that repeat at intervals that

can be measured.

• If the defect occurs every 44 mm on the prints, do not replace

the drum. This interval is caused by a damaged or defective

Developer Housing.

• If spots or bands occur every 147 mm on the prints, a Drum is

damaged or light shocked. Replace or swap the appropriate

Drum cartridgerefer to Drum Cartridge.

• If the defect occurs every 374 mm on the prints, replace the

Fuser Belt Assembly; contact the Customer Support Center.

Streaks or Lines

The prints show solid color

streaks or lines running

from Lead Edge to Trail

Edge (LE/TE) of prints. For

IQ defects that runInboard

to Outboard (IB/OB); refer

to Banding.

• Perform the Cleaning the ROS Windows procedure.

• Acquire the measuring tool from the Nationalization Kit. Check

the frequency of the defect intervals. If spots or bands occur

every 147 mm on the prints, a Drum is damaged or light

shocked.Replace or swap the appropriate Drum cartridge; refer

to Drum Cartridge.

If you run multiple width papers, refer to Fuser Hints and Tips and

Extended Fuser Life for more information.

Edgewear

The IB and OB edges of the

output prints shows dry ink

/ toner deletions, density

inconsistency, or is lacking

in color depth; occurs

mainly when using heavier

or lighter weight stock.

Refer to the Custom Paper Settings Troubleshooting table, and

review the Suggested Solutions for Uneven Density / Mottle.

Halo or smudges

6-9Xerox

®

Versant

®

180 Press

User Guide

Troubleshooting

Loading...

Loading...