<3. Operation>

3-19

IM 01C25T03-01E

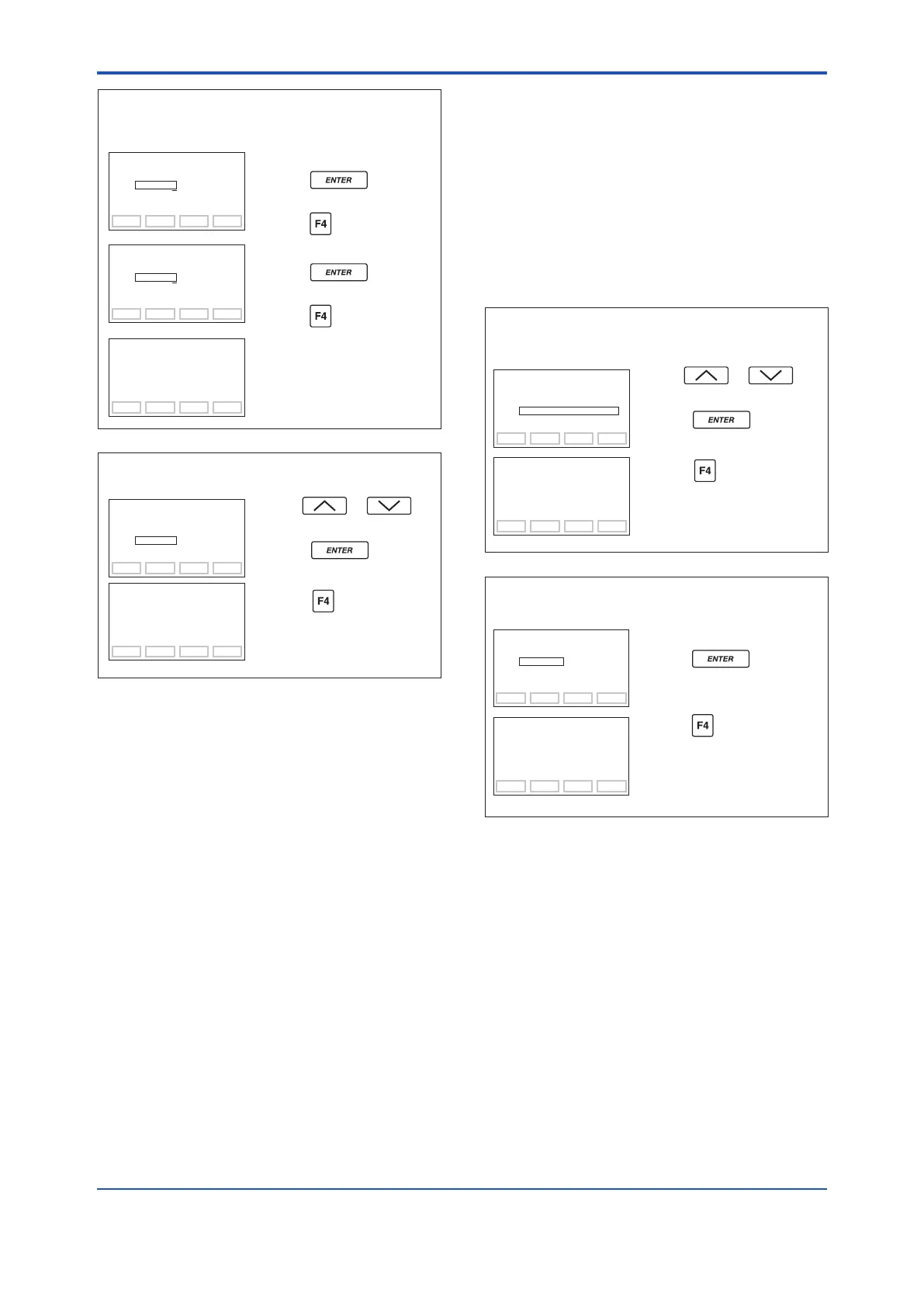

• Example: Set the first coordinates (X1, Y1) as

(12, 14) in %.

ESCCLR

SET

T23:Y1

10.00%

+ 014.00

CLR ESC

SET

T22:X1

10.00%

+ 012.00

F0346.ai

PARAM

T21:Y

0.00%

T22:X1

12.00%

T23:Y1

14.00%

PRNTDATA DIAG ESC

Set 12 for X1.

Press the key twice to

enter the setting.

Press the (OK) key.

Set 14 for Y1.

Press the key twice to

enter the setting.

Press the (OK) key.

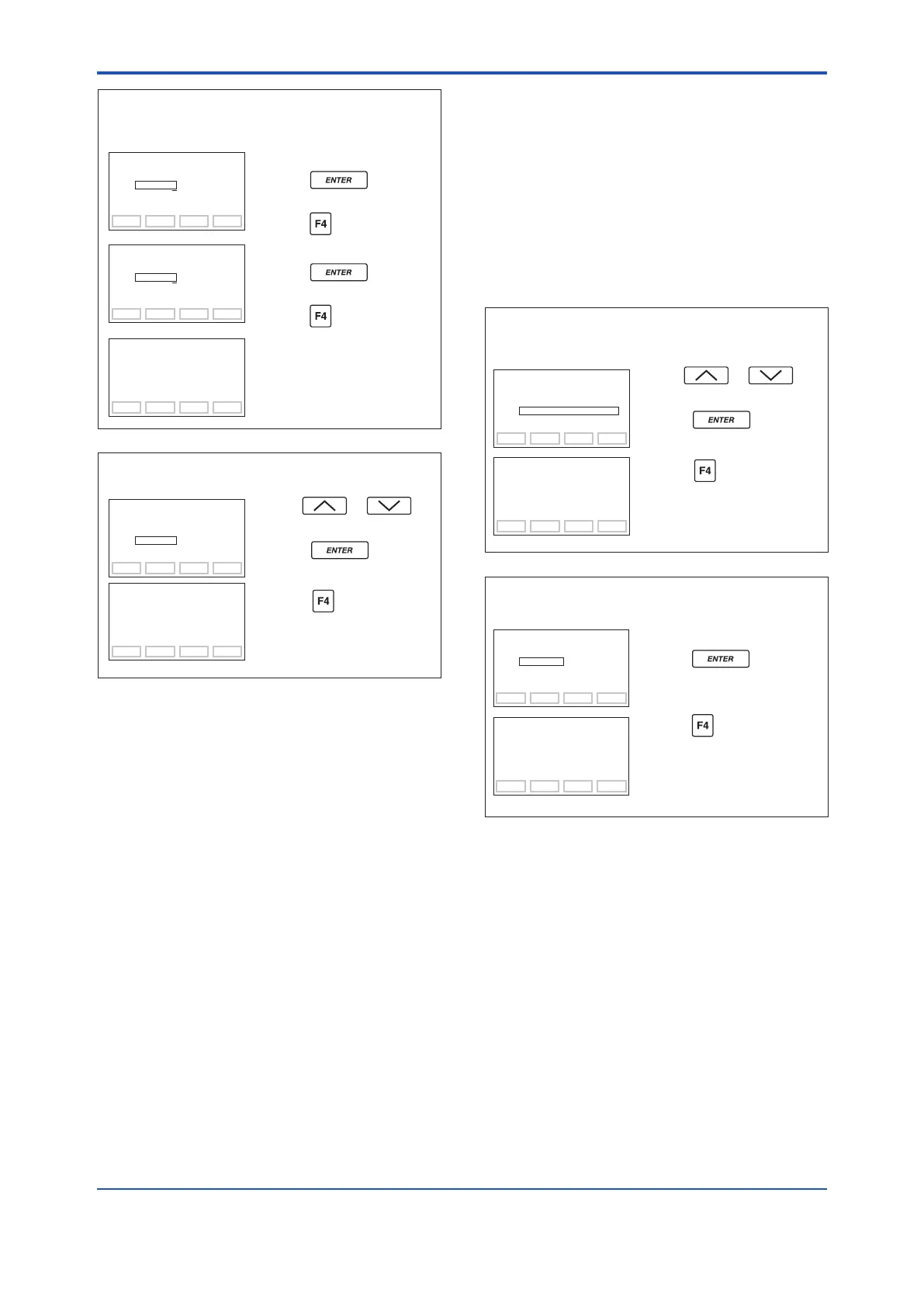

• Example: Set the signal characterizer ENABLE.

ESC

SET

T10:S.C.ENABLE

ENABLE

FEED NO OK

SET

T10:S.C.ENABLE

INHIBIT

< INHIBIT>

< ENABLE >

F0347.ai

Use the or key

to select ENABLE.

Press the key twice to

activate the function.

Press the (OK) key.

(18) Process Alarm

(G10: P AL MODE, G11: P HI.AL VAL,

G12: P LO.AL.VAL)

The function is used to display the alarm codes

whentheinputpressureexceedsthespecied

value within the calibration range. The same is

available for the input static pressure and the

capsule temperature on the pressure sensor.

Refer to table 4.1 Alarm Message Summary for the

specicalarmcodetobegenerated.

• Example: Set alarm mode from OFF to HI.AL

DETECT.

ESC

SET

G10:P AL MODE

HI.AL DETECT

FEED NO ESC

SET

G10:P AL MODE

INHIBIT

< INHIBIT >

< HI.AL DETECT >

< LO.AL DETECT >

< HI/LO.AL DETECT >

Use the or key

to select HI. AL DETECT.

Press the key twice to

enter the setting.

Press the (OK) key.

Alarm code is generated when the

output goes beyond the value set

at G11: P HI. AL VAL.

F0348.ai

• Example: Set the higher alert value of 75 for

alarm generation.

CODE CAPS CLR ESC

SET

G11:P HI.AL VAL

75.0000 kPa

FEED NO OK

SET

G11:P HI.AL VAL

100.000 kPa

+ 75

Set 75.

Press the key twice to

enter the setting.

Press the (OK) key.

Then the alarm code “AL.35 P. HI”

is generated when the input

pressure goes beyond that value.

F0349.ai

Loading...

Loading...