Communication protocol 137

Parameter handling in cyclic communication (DP)

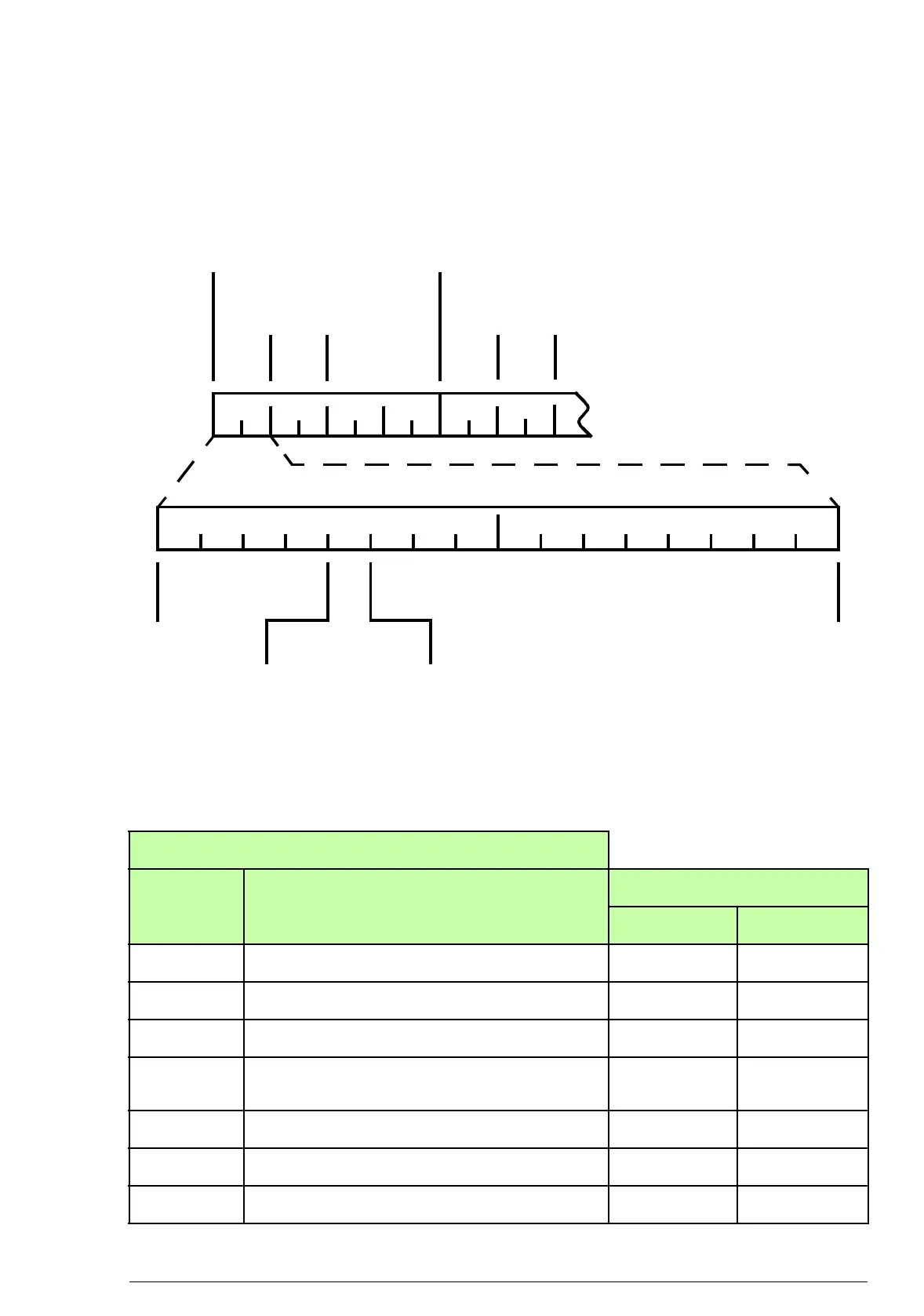

In cyclic PROFIBUS DP communication, parameter data is

transferred in PPO message types 1, 2 and 5, as shown in section

PPO types on page 135. The parameter identification part consists

of eight bytes, as shown below.

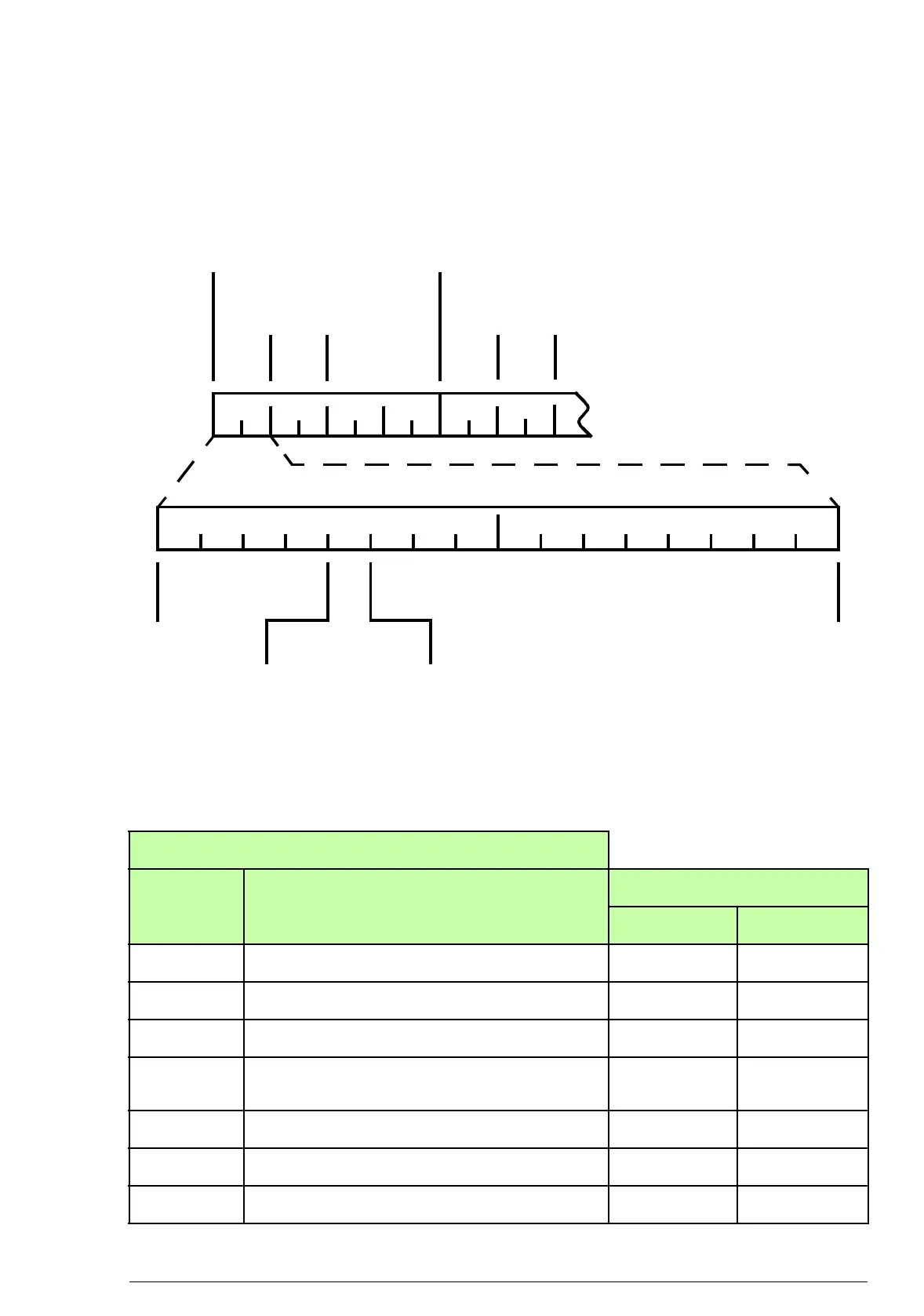

The Request label is used by the master when transmitting data to

the slave, while the Response label is used by the slave as a

positive or negative acknowledgement. The tables below show the

Request/Response functions.

Request labels (from master to slave)

Request Function Response labels

Ackn. (+) Ackn. (-)

0No task 0 –

1 Request parameter value 1, 2 7

2 Change parameter value (word) 1 7, 8

3 Change parameter value (double

word)

27, 8

4 Request description element 3 7

5 Change description element 3 7, 8

6 Request parameter value (array) 4, 5 7, 8

ID IND VALUE

15 14131211109876543210

Request label

Response label

Request signal

Parameter number (PNU)

Process data

Parameter

identification

Not used (=0)

CW REF

(PD1, PD2...)

SW ACT

Loading...

Loading...