Operation Manual / 4 Product description / A100-L

8 Disassembly and assembly / 8.4 Dismantling the filter silencer

© Copyright 2017 ABB. All rights reserved. HZTL4034_EN Revision K June 2017

8.4 Dismantling the filter silencer

8.4.1 Design variants

The turbocharger is equipped with one of the following filter silencer variants:

¡ Welded filter silencer

¡ Cast filter silencer

The filter silencers differ in terms of the fixing eyelets for the lifting gear. The relevant vari-

ant must be taken into consideration for disassembly and assembly.

8.4.2 Dismantling the filter silencer (welded)

If the turbocharger is also fitted with a noise package, chapter Dismantling the filter silencer

with noise package →61 must be observed.

u Dismantle the insulation if necessary.

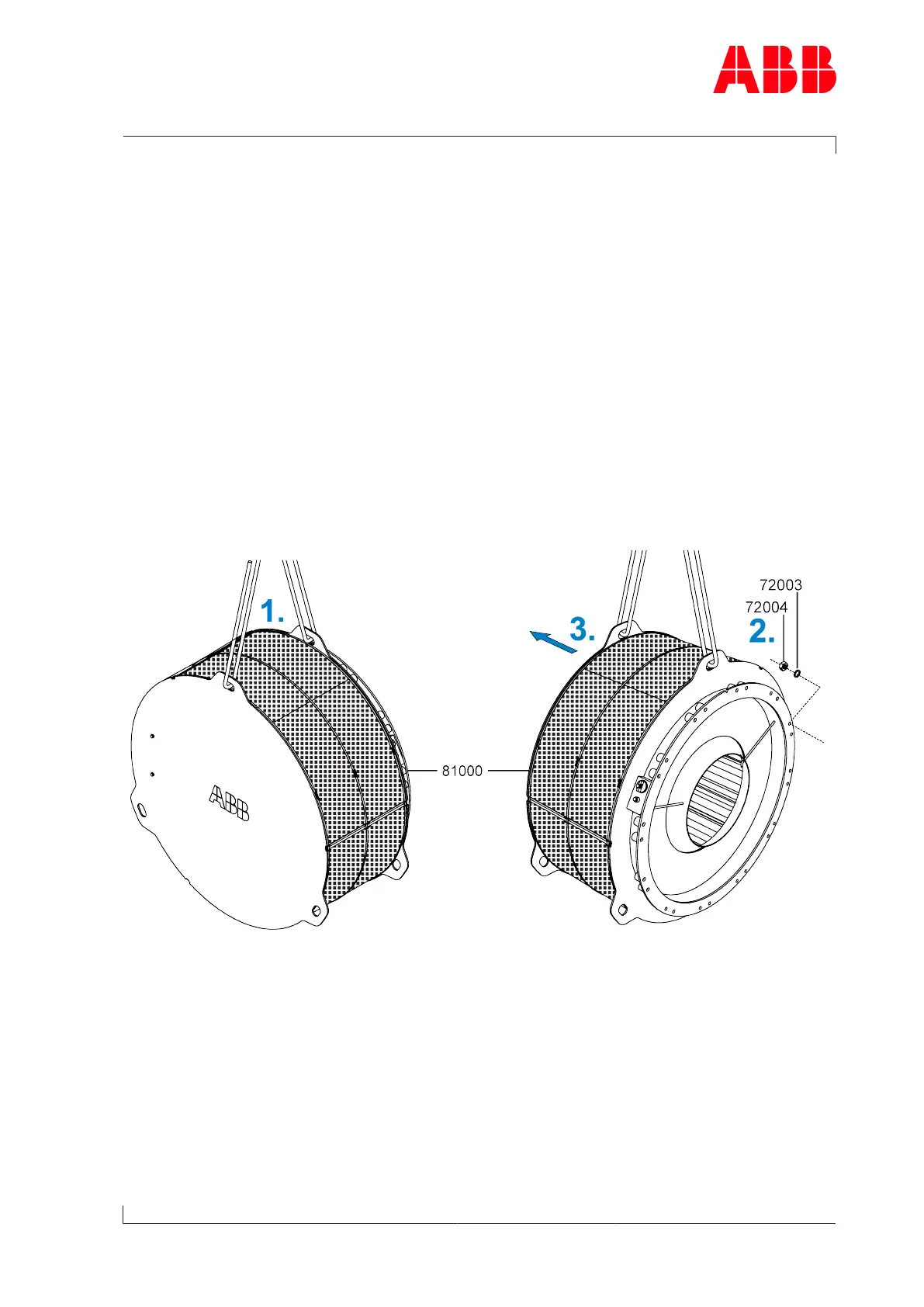

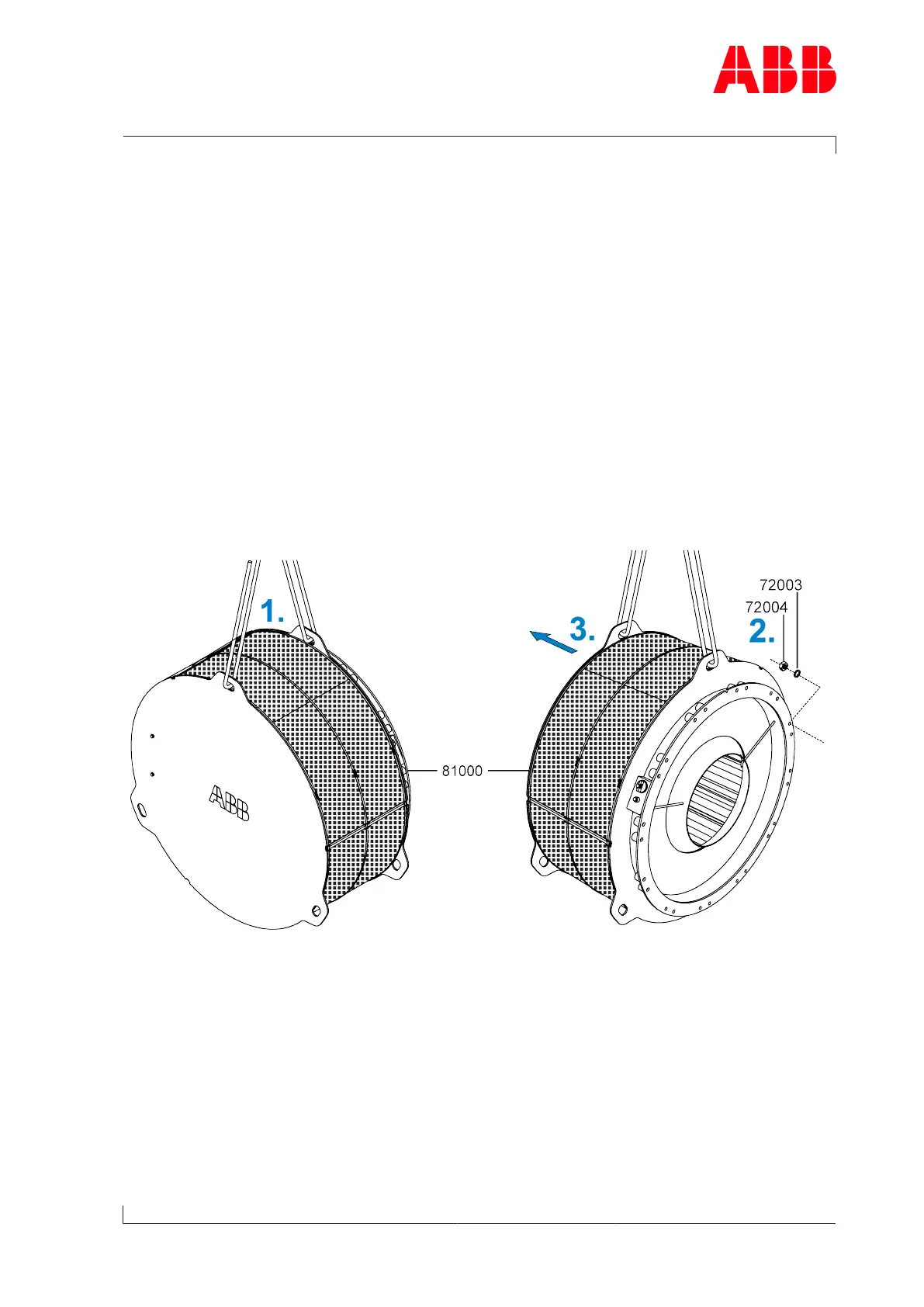

Fig.29: Dismantling the filter silencer

1. Attach lifting gear to the eyelets of the filter silencer (81000).

2. Loosen nuts (72004) and remove with washers (72003).

3. Remove and put down filter silencer.

Page 59 / 106

Loading...

Loading...