ASSEMBLY INSTRUCTION (refer to Fig. 6)

1. Take out from the packaging the wall plate and the drilling template 1.

2. Position the drilling template 1 on the radiographic system installation wall, at the required height (130cm

from the base in the suggested height).

3. Fix the template 1 with adhesive tape.

4. Check the holes for verticality and alignment with the oor, using a plumb line.

5. Mark the wall plate 8 xing holes.

6. If required, mark the holes for the electric cables connecting the timer to the tubehead.

PLEASE NOTE

To prevent any aking in the white coat and to control the centre distances between the holes, it is advisable to start drilling with a tip Ø7,

increasing this measure gradually.

7. Drill the xing holes.

8. Remove the template 1 and insert the suitable anchor screws 2, according to the wall characteristics.

9. Unscrew the screw 3 and remove the plug 4 from the wall plate 8.

10. Withdraw the sliding cover 5.

11. Approach the wall plate 8 to the wall and insert the screws 7 with the relevant washers 6, then tighten

alternately.

12. Check that the wall plate 8 is steadily xed to the wall.

PLEASE NOTE

If the wall is not perfectly levelled, put a suitable shim between the wall and the wall plate, so as to prevent any possible deformations.

4.4. ASSEMBLING THE BRACKET

PLEASE NOTE

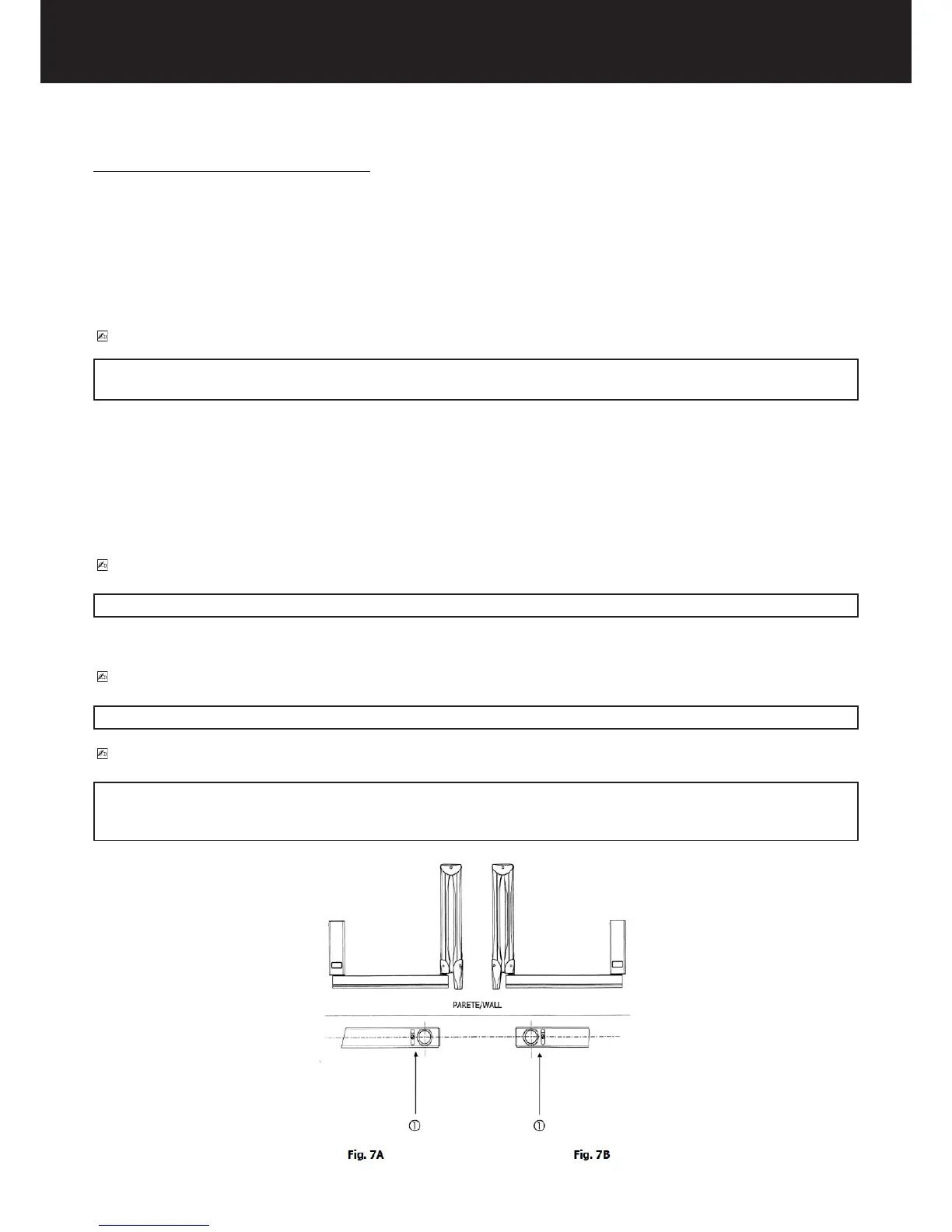

The 82,5cm and 110cm brackets are provided with a stop key 1 (Fig. 7A and 7B) to prevent the electric cable from twisting.

PLEASE NOTE

Generally, the stop key is installed so that the equipment position at rest is on the right side of a possible watcher standing in front of the

wall plate (Fig. 7A). Should the position at rest be on the left side, the stop key must be rotated by 180° (Fig. 7B).

Loading...

Loading...