TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

1.6.10.5 Engine cowlings

There are two laminated cowlings. The disassembly of a upper cowling is easy, just

release the quick-closing locks. The quick-closing locks releases by means of a

suitable screwdriver with a 90° counterclockwise slewing. The releasing starts at a rear

corner with the simultaneous raising of the cowling. The quick-closing locks releases

have to remain over a cowling until the disassembly of a all cowling.

The lower cowling is removed after unscrew the attachment screws connecting the

cooler to the cowling face side, then unscrew the attachment screws connecting the

cowling to the firewall border. The coolers remain connected with the inlet hoses.

1.6.10.6 Engine lubrication system

The ROTAX 912 engine is provided with a dry sump forced lubrication system. The

oil pump is driven by the camshaft. The oil pump sucks the motor oil from the oil tank

via the oil cooler and forces if through the oil filter to the points of lubrication in the

engine.

The surplus oil emerging from the points of lubrication accumulates on the bottom of

crankcase and is forced back to the oil by the blow-by gases. The oil tank is equipped

with a venting hose. The oil temperature sensor for reading of the oil inlet temperature

is located on the oil pump housing.

Refer to the Operator’s Manual for all versions of ROTAX 912 for additional

information.

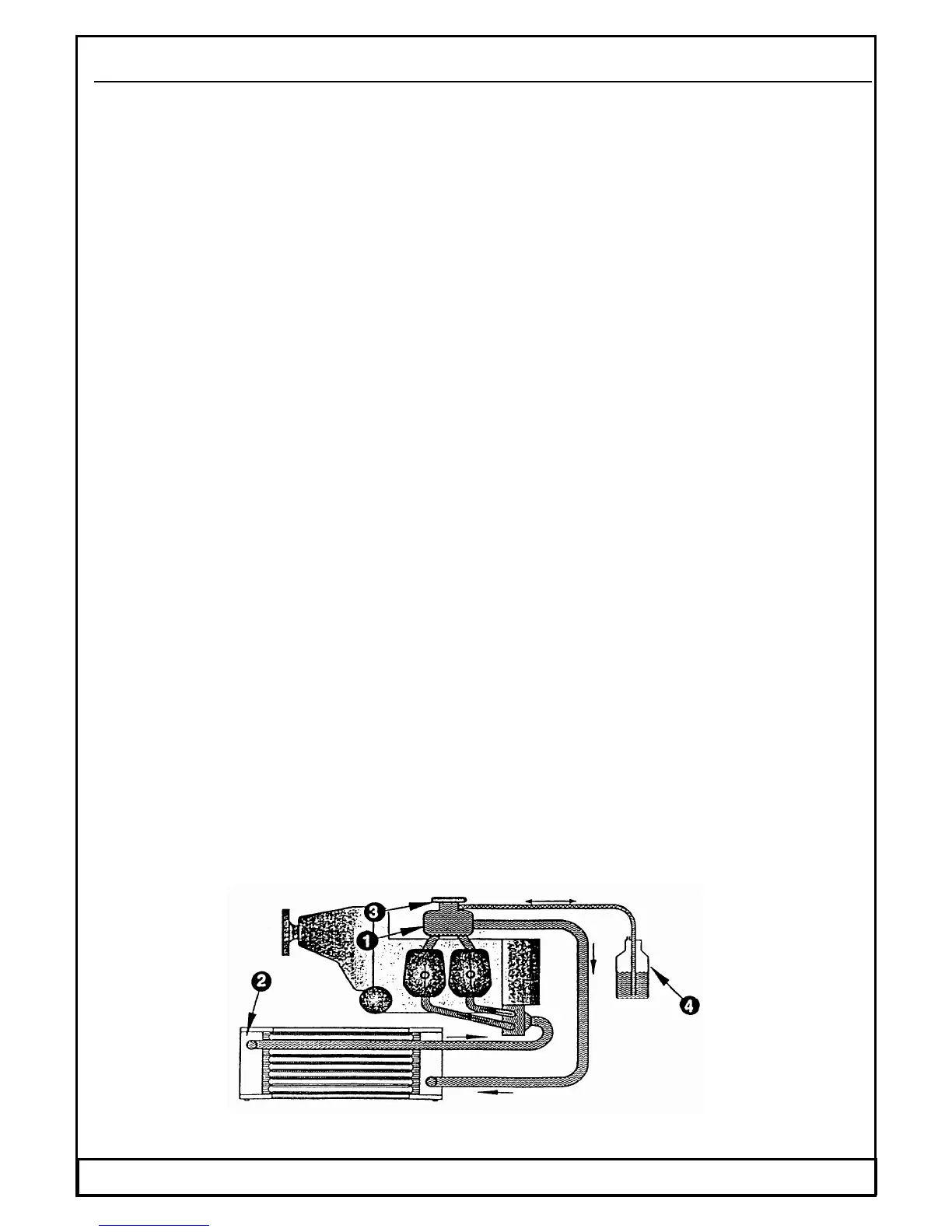

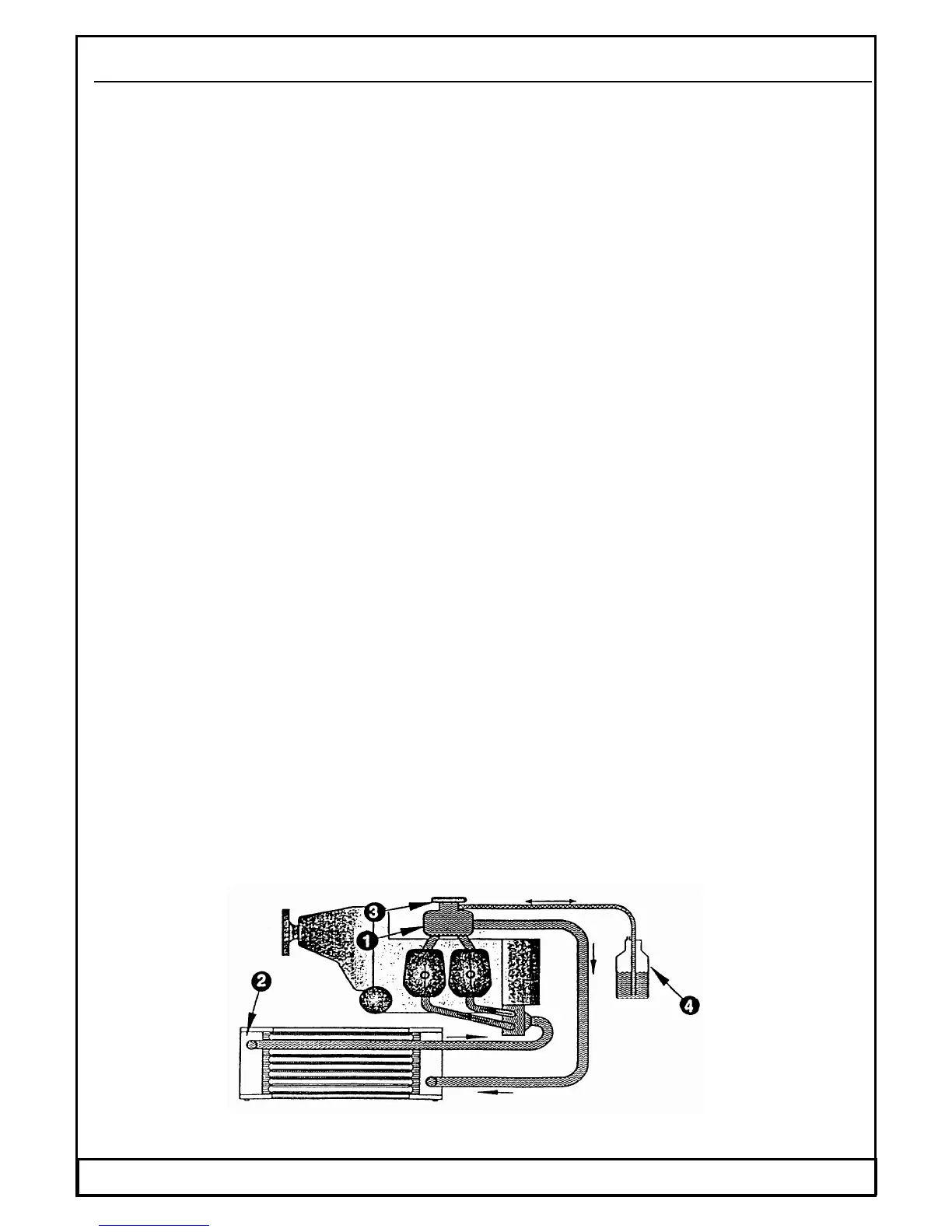

1.6.10.7 Engine cooling system

The cooling system of the ROTAX 912 engine is designed for liquid cooling of the

cylinder heads and ram-air cooling of the cylinder. The cooling system of the cylinder

heads is a closed circuit with an expansion tank and with a overflow bottle. The

coolant flow is forced by a water pump, driven from the camshaft, from the radiator to

the cylinder heads.

From the top of the cylinder heads the coolant passes to the expansion tank (1). Since

the standard location of the radiator (2) is below engine level, the expansion tank

located on top of the engine allows for coolant expansion. The expansion tank is

closed by a pressure cap (3) ( with excess pressure valve and return valve ). At

temperature rise of the coolant the excess pressure valve opens and the coolant will

flow via a hose at atmospheric pressure to the transparent overflow bottle (4). When

cooling down, the coolant will be sucked back into the cooling circuit.

A direct reading of the coolant temperature is not taken. The coolant temperatures are

measured by means of temperature probes installed in cylinder heads. This system

allows for accurate measurement of engine temperature, even in event of fluid loss.

Fig. 20 Engine cooling system

Date: 01.03.2002 WT-9 Dynamic Section 1 Page 1 - 27

Loading...

Loading...