* *

2

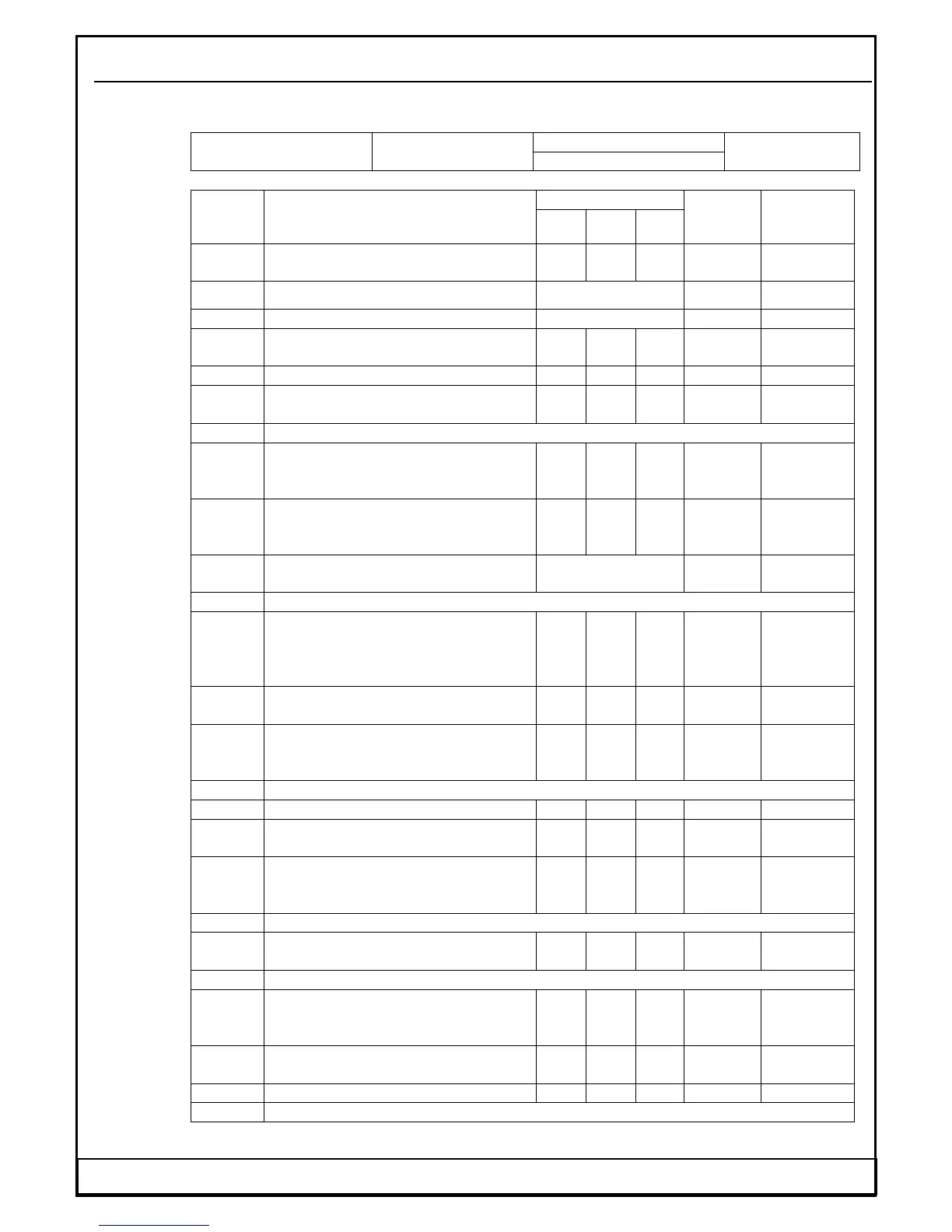

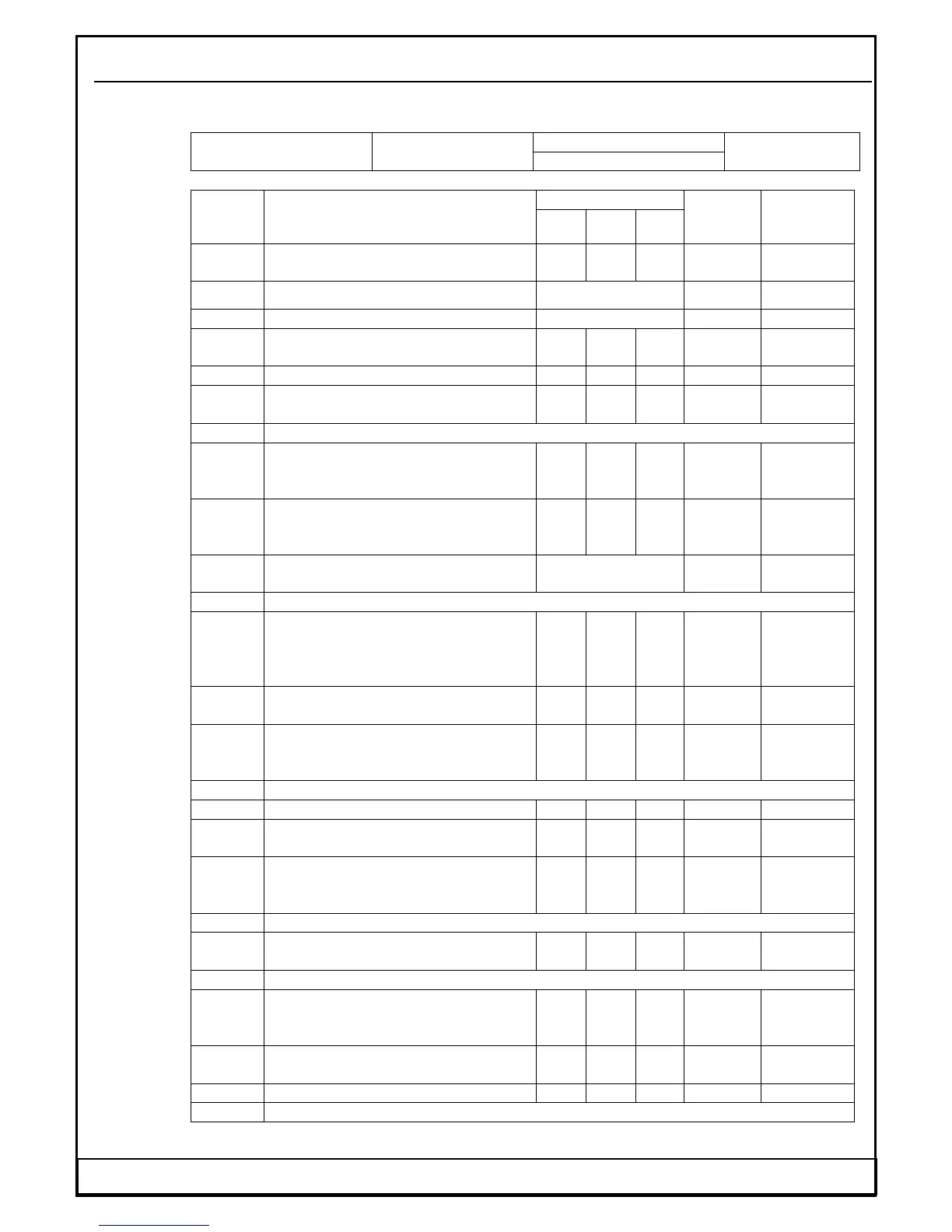

ENGINE

See engine manufacturer ´s

instructions

2.1

Laminated engine cowlings

2.1.1 Check condition of cowlings and quick

closing locks-repair found damages

*

2.1.2 Remove engine cowling * * *

2.1.3 Visually check fireproof primer- repaint

if need be

* *

2.2 Engine bed

2.2.1 Visually check condition, attachment,

security of attachment bolts: engine-

engine bed, engine bed-firewall

* * *

2.2.2 Visually check condition of rubber

silentblocks-replace those cracked and

excessively deformed

*

2.2.3 Check the engine mount screws for

cracks and damage

After 600 flight hour

operation

2.3 Suction system

2.3.1 Visually check condition, integrity,

attachment and security of air filter at

carburettor inlet - clean impure filter

according to the engine manual

* * *

2.3.2 Visually check condition of suction

piping

* * *

2.3.3 Check carburettors – condition, control

cables attachment, lubricate cables at

inlet to the bowdens

* * *

2.4. Battery

2.4.1 Visually check attachment and security * *

2.4.2 Check charging – charge battery if need

be

*

2.4.3 Visually check condition and

attachment of wire leads-replace those

damaged

* * *

2.5. Wiring

2.5.1 Visually check condition and integrity

of wires, connections, security of wires

* * *

2.6. Fuel system

2.6.1 Visually check condition, integrity,

attachment and security of hoses –

replace those damaged

* * *

2.6.2 Visually check fuel filter condition-

replace impure filter

* * *

2.6.3 Visually check system for leakage * * *

2.7. Cooling system

Hours flown: Type: WT-9 Dynamic Registration:

No. of Take-offs:

Date of inspection:

Date: 01.03.2002 WT-9 Dynamic Section 3 Page 3 - 4

Loading...

Loading...