TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

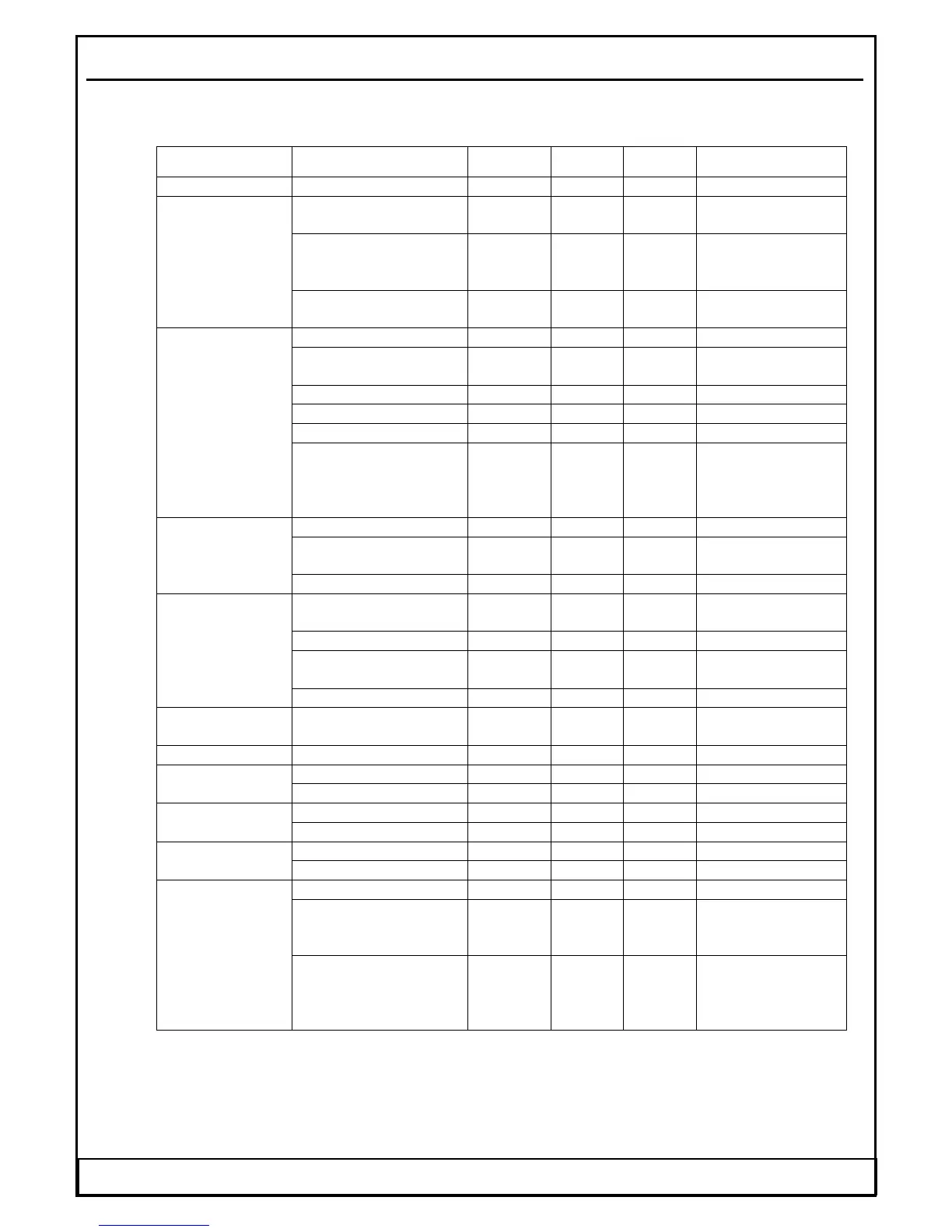

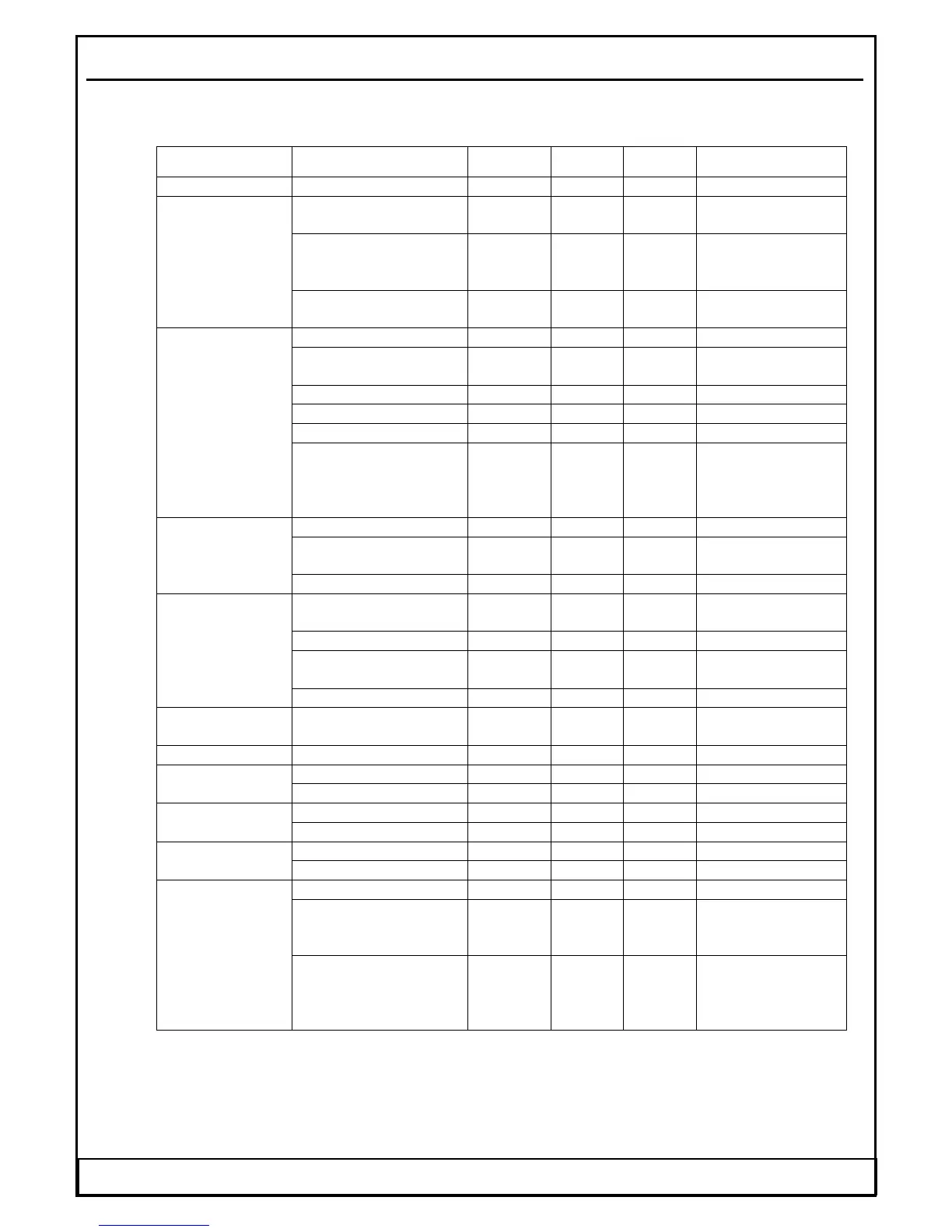

3.8.3 Lubricating points

Unit Lubricating point

After

25hr

Every

50 hr

Every

100 hr

Lubricant

Propeller See ManufacturerManual

Engine

* choke control cables at

inlet into the termination

* * Oil the control cables

*wheel bearings * Lubricate by grease

*swing wheel fork joint

pins

* * * Grease nipple

Lubricate by grease

* drag stay pins * Lubricate by grease

* gas strut pins * Lubricate by oil

* upper and down leg pin

* * Lubricate by grease

Nose wheel

landing gear (

retractable

undercarriage )

* swivel bearings in the

cables terminations close

to the nose wheel control

levers

* Lubricate by grease

* wheel bearings * Lubricate by grease

* upper and down leg

locating bush

* * Lubricate by grease

Nose wheel

landing gear

( fixed

undercarriage )

* joint pins of the control

* * Lubricate by grease

* swing wheel fork joint

pins

* * * Grease nipple

Lubricate by grease

* drag stay pins * * Lubricate by grease

* hydraulic face rams

pins

* Lubricate by grease

Main landing gear

(retractable

undercarriage )

* wheel bearings * Lubricate by grease

Hand control *control stick bearings

and all movable joints

* Lubricate by grease

Foot control * all movable joints * Lubricate by grease

*supporting bearings * * Lubricate by grease Ailerons

*rod end bearings * * Lubricate by grease

*sliding bearings * Lubricate by grease Rudder

*rudder lever pins * * Lubricate by grease

* all movable joints * * Lubricate by grease Elevator

*supporting bearings * Lubricate by grease

* rod sliding bearings * Lubricate by grease

*rod joint pins * Lubricate by grease

at each flaps

disassembly

Flaps

*Changing gate guided a

flap control lever in the

pedestal between the

pilot seats

* * Lubricate by HHS

2000 oil (Würth

Firm)

Date: 01.03.2002 WT-9 Dynamic Section 3 Page 3 - 16

Loading...

Loading...