TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

4.6 Repair class 4

The erosion damages caused by the rain, the scores, the scrapes without the outer glass

fiber laminate damage require the lacquer works only. Suitable is PE – Lackvorgelat ,

white No.3-69469 and PE – Hardener No. 07-20500. Mixing proportions by weight 100

parts Lackvorgelat to 10 parts hardener. The lacquer remains to gell ( appr. 30 minutes )

for filling more deep scrapes. In case of first cloth layer damage, then whole repair area

cleans well and sands smooth with an abrasive paper. Lay on the cloth layer and, if the

resin is dry, the repair area can be puttied and repainted with lacquer.

4.7 Repair class 3

If the outer shell receives a puncture or a fracture, tap to determine the extent of

delamination from the foam. Follow by removing the lacquer with a sanding disc or

block and remove from the foam the portion of the shell which has become delaminated.

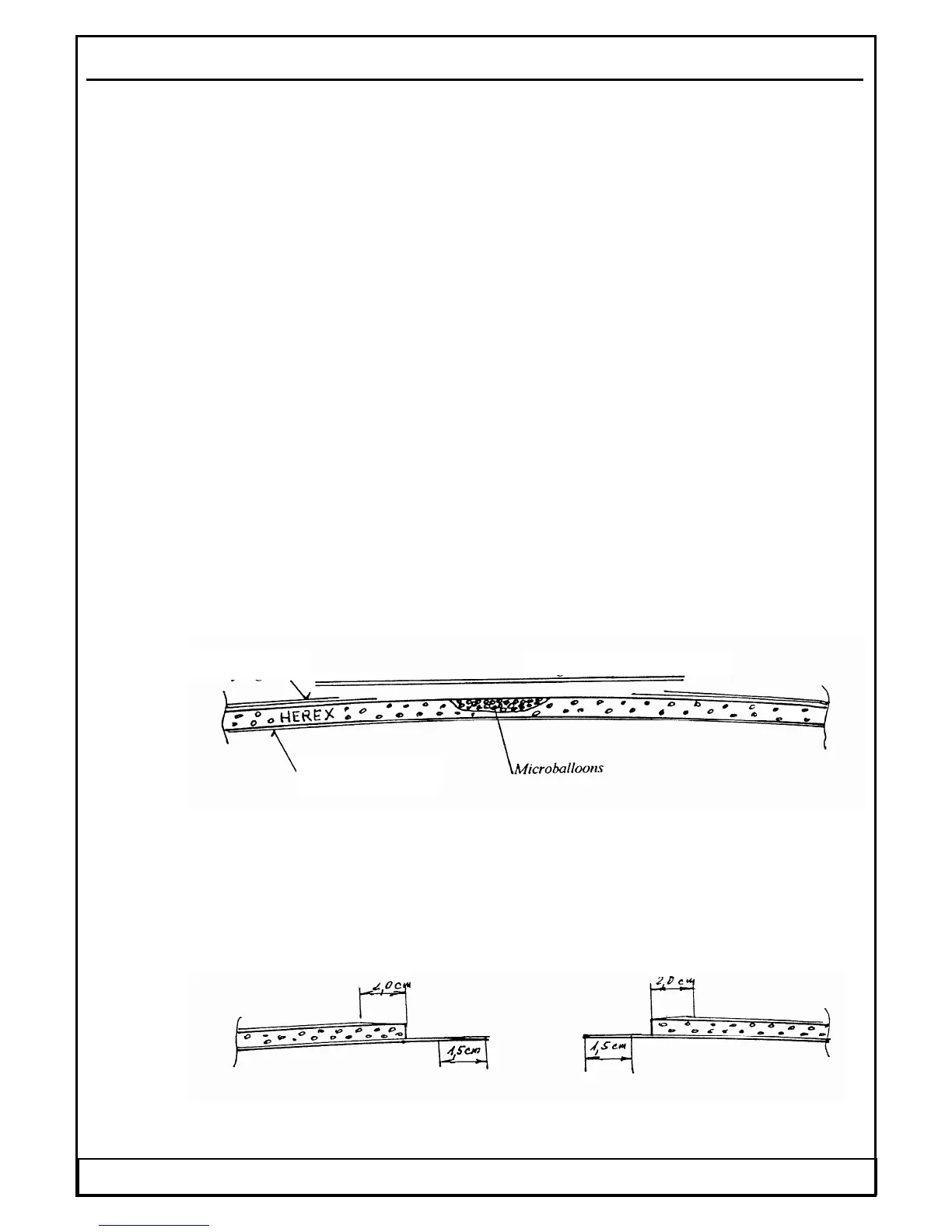

Around the edge of the damaged area where the shell is still firmly bonded, scarf with an

abrasive block or a plane blade at least 4 cm ( for each cloth layer about 15 mm is

necessary ). After scarfing the shell, blow out thoroughly the whole repair area including

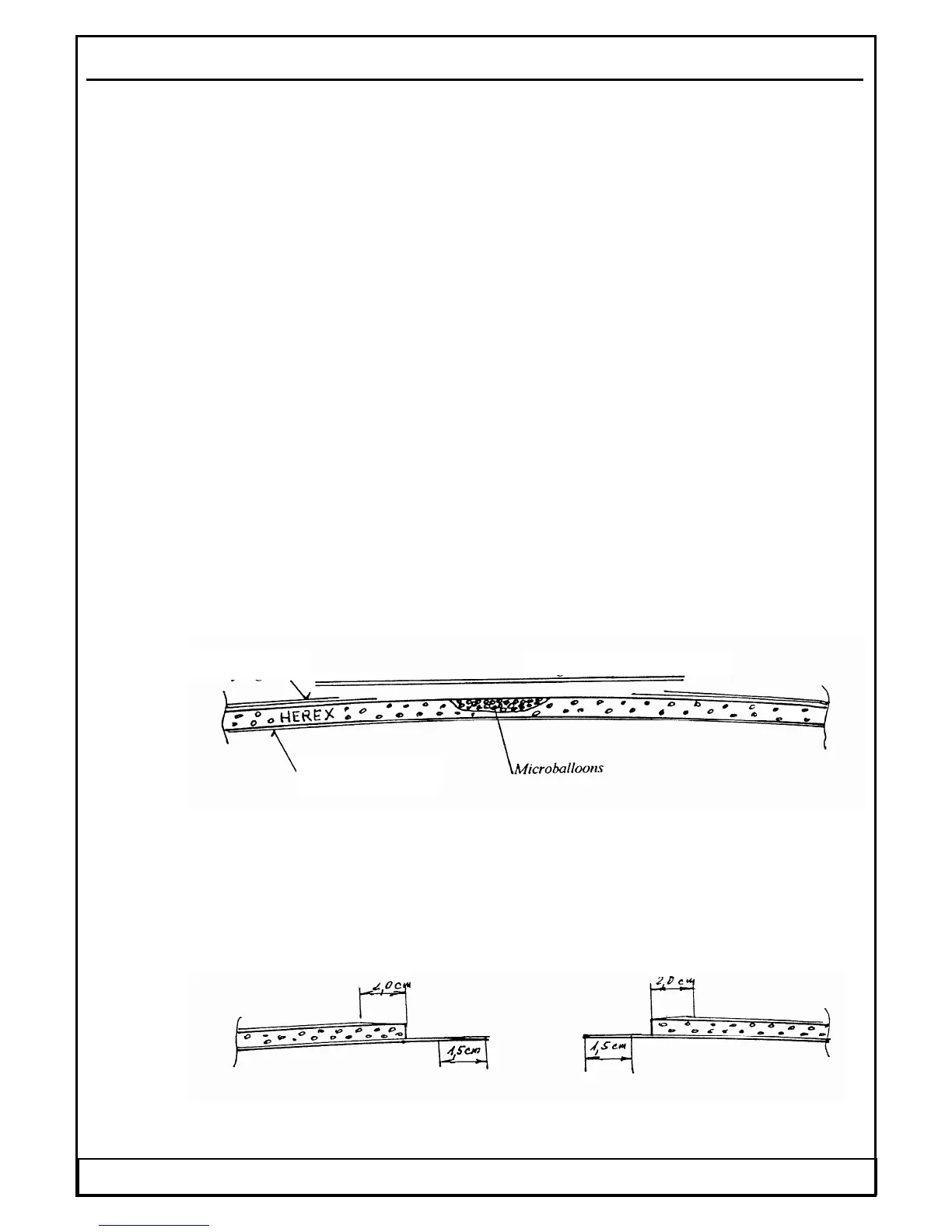

the pores of the foam and wash the scarf with carbon tetrachloride or acetone. Now fill

the hole in the foam with microballoons and simultaneously fill the pores of the exposed

foam. Then lay two patches of the 92110 cloth with diagonal weave direction ( stepwise

largest patch first ) over the damaged area. The applied cloth must be dry and dust free.

After hardening ( appr. 8 hrs at 20°C ) the damaged area should be smoothed, filled and

painted. In smoothing take care that only the edges of the patches are sanded.

4.8 Repair class 2

If there is a through hole in the sandwich shell then the inner laminate must be repaired.

We remove the outer laminate in the region of the region of the damage which is no

longer bonded to the foam and enlarge the hole in the foam and inner laminate until good

bonding to the foam is evidenced. Then the foam is further removed 20 mm around the

hole in the inner laminate and the outer laminate scarfed as under Repair class 3.

Date: 01.03.2002 WT-9 Dynamic Section 4 Page 4 - 4

Inner lami

Loading...

Loading...