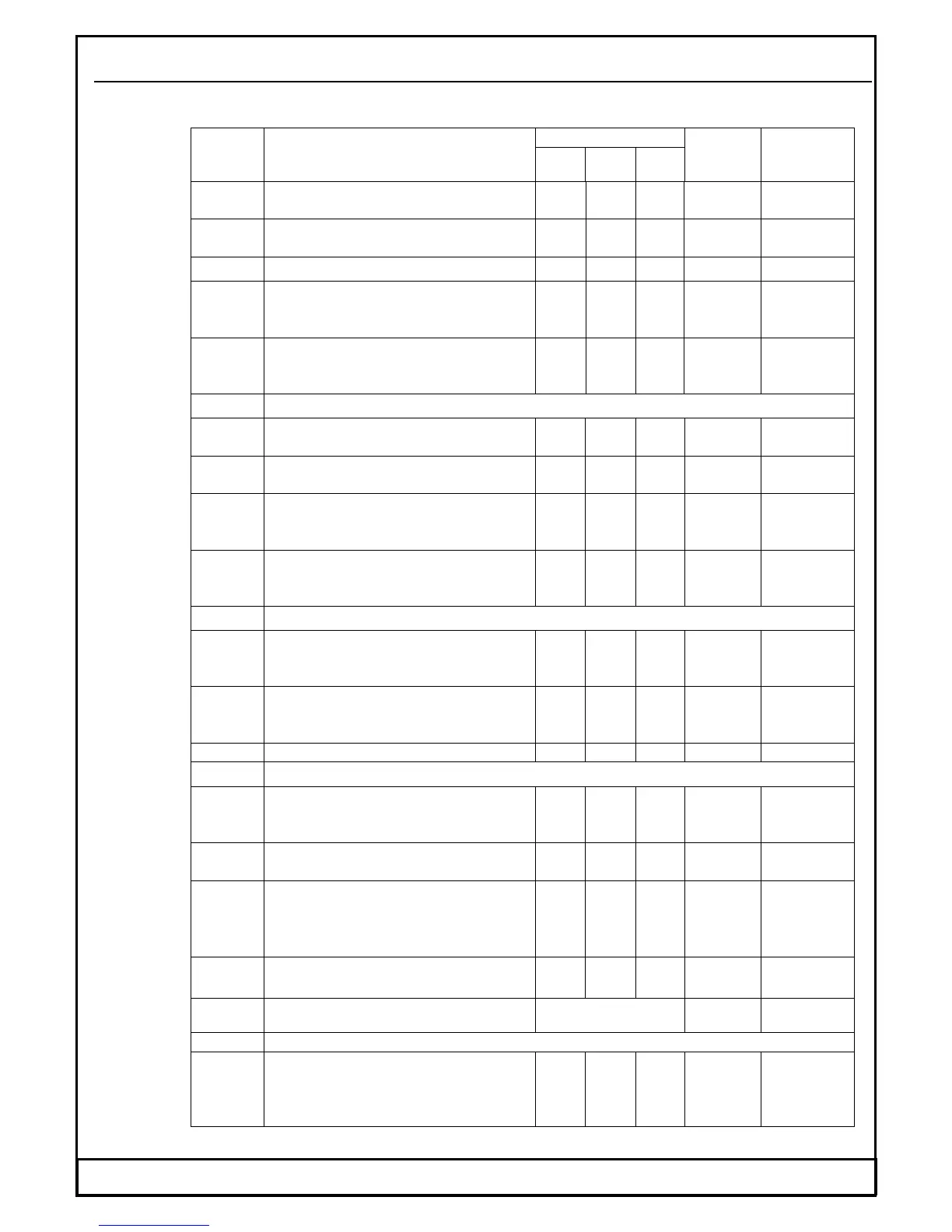

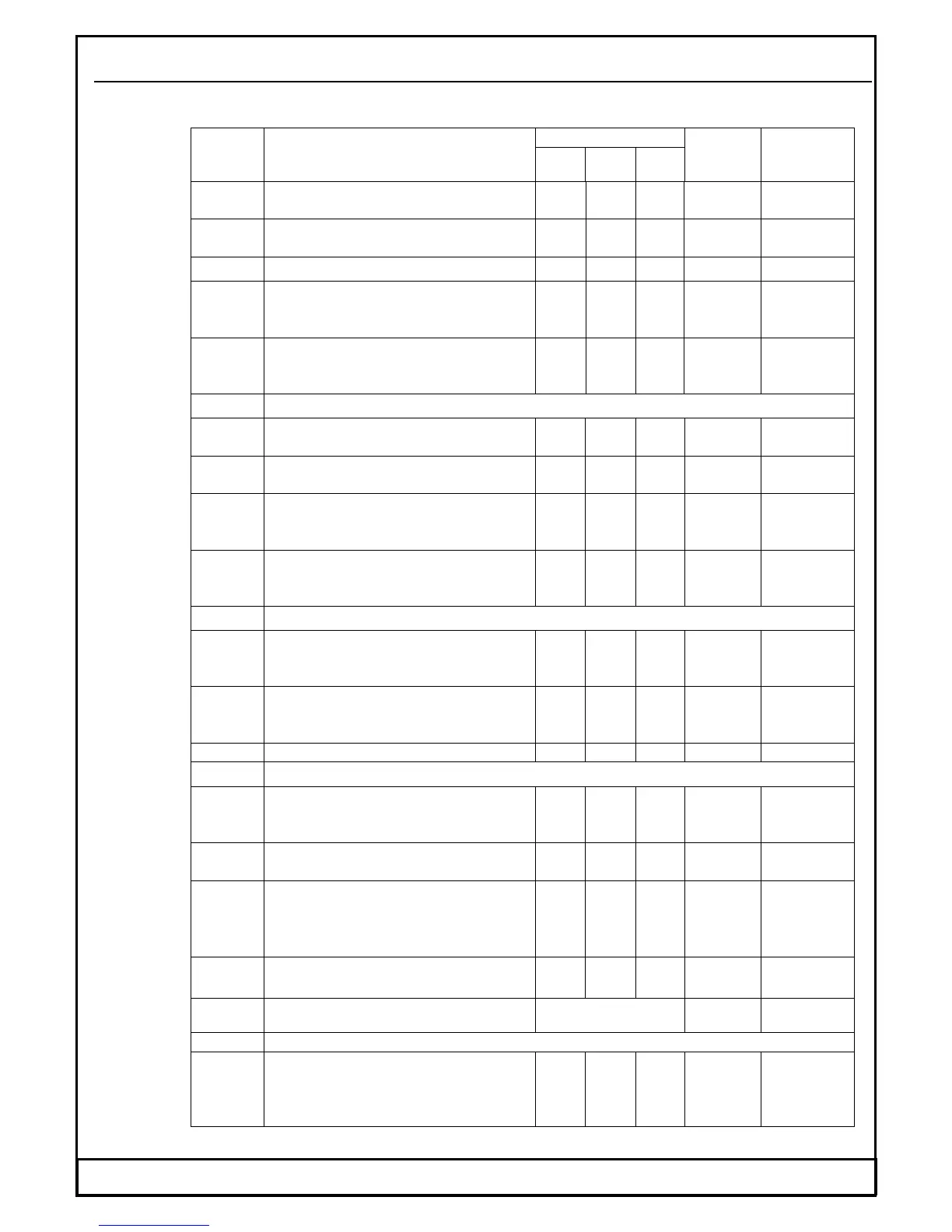

TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

Inspection after Event Event description

First

25 hr

every

50 hr

every

100hr

Carried

out by:

Inspected

by:

2.7.1 Visually check cooler for condition and

leakage

*

2.7.2 Visually check condition, attachment of

hoses, check system for leakage

* * *

2.7.3 Tighten hose clips if need be

* *

2.7.4 Check coolant quantity in the expansion

tank-add or change coolant according to

the ROTAX engine manual if need be

* * *

2.7.5 Visually check condition and

attachment of overflow bottle on the

firewall

*

2.8 Lubrication system

2.8.1 Visually check condition and

attachment of oil tank

*

2.8.2 Check oil cooler for condition,

attachment and leakage

* * *

2.8.3 Visually check hoses for condition ,

leakage, attachment and security-

replace damaged hoses

* *

2.8.4 Check oil quantity – add or change oil

according to the engine manual if need

be

* * *

2.9 Exhaust system

2.9.1 Visually check exhaust system for

condition, cracks, deformations or

damage – repair ( weld )

* * *

2.9.2 Visually check condition and

attachment of the muffler-weld found

cracks

* * *

2.9.3 Check joints security * * *

2.10 Heating

2.10.1 Visually check hose leading hot air into

the cockpit-check hose for condition,

integrity, attachment and security

* * *

2.10.2 Check condition, function and control

of the heating flap

* *

2.11 Reinstall lower engine cowling

Upper engine cowling reinstall when

the inspection is completed and engine

test run performed

* * *

2.12 Lubricate according to the

Lubrication Chart

* * *

3. PROPELLER

see manufacturer

instruction

3.1 Blades

3.1.1 Inspect blades for abrasions, cracks,

paint damage, condition of blades

leading edges and tips-repair according

to the propeller manual

* * *

Date: 01.03.2002 WT-9 Dynamic Section 3 Page 3 - 5

Loading...

Loading...