TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

The given mixing proportion of components must be observed as exactly as possible.

Mixture of a resin and a hardener must be stirred thoroughly until there are no cloudiness

and no bubbles in a vessel. The thickeners and the resin-fillers are added after stirring.

The hardening of the mixture is 15 hours at a temperature 55 °C. The mixture reaches

final properties after this time.

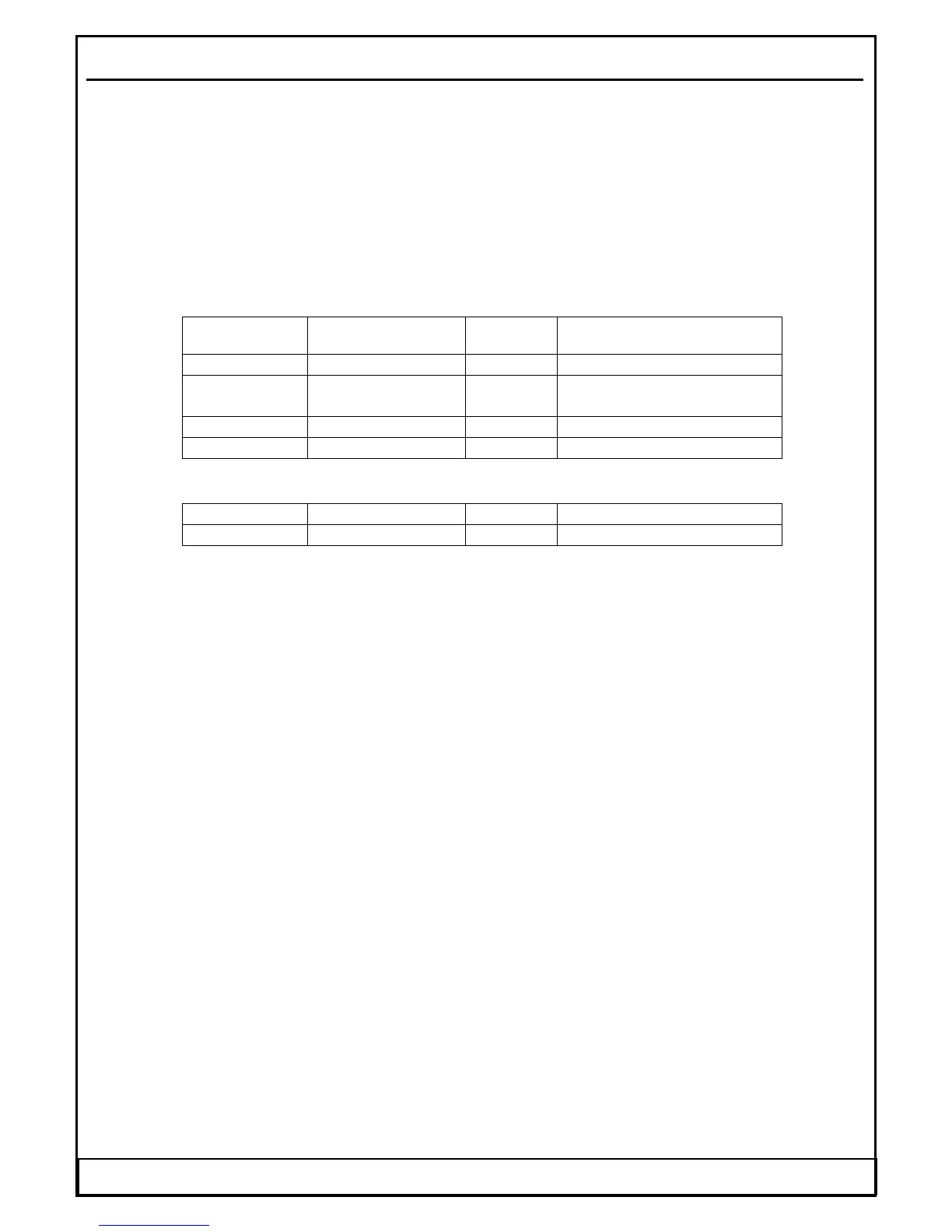

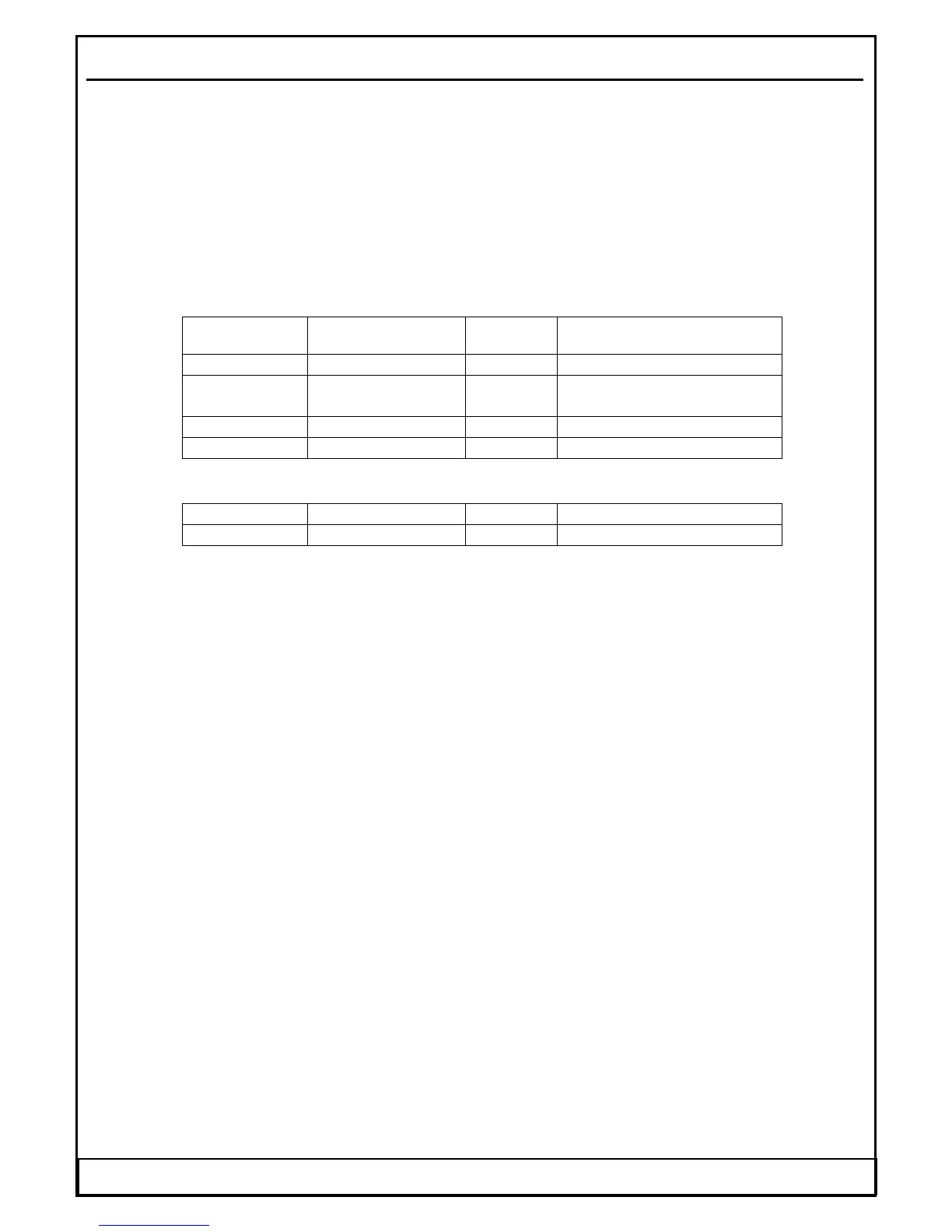

Reinforcements:

Glass clothes

INTERGLAS

Style

Weave

Weight

g/m

2

Application

91110 Crosstwill 110 Inner skins

92110 Crosstwill 163 Fuselage, wing, control

surfaces

92125 Crosstwill 285 Fuselage, wing

92145 Unidirectional 216 Fuselage, wing

Carbon clothes

98140 CF 200 Cloth 200 Fuselage

CF 140 Unidirectional 140 Fuselage, stabilizer

Rovings

Carbon : TENAX HTA 5131

Glass : EC9-756 K43

Foams : HEREX C.70.55

Resin - Fillers : Aerosil, Chopped cotton wool, Microballoons

white

Lacquer : Acryl

Steel :

L-CM3.6 ( AISI 4130, DIN 1.7214.4 )

Light metals : Duralumin Z 424203.61 ( ASM 2024 )

4.5 Repair preparation

You should first inspect the damaged area to determine exactly the extent of damage,

type of construction and type and density of weave concerning to main dimensions of the

part. The aeroplane WT-9 Dynamic has the first layer of the sandwich outer layers from

the 92110 cloth with 45 ° diagonal weave direction to the fuselage centre line or to the

wing centre line. The first step is removing all damage parts and all portion of the shell

which has become delaminated from a damage area. A repair area should be washed with

a soap and dried up. Then clean a repair area with carbon tetrachloride or acetone.

Prepare clean vessels for stirring the mixtures of a resin and a hardener.

Date: 01.03.2002 WT-9 Dynamic Section 4 Page 4 - 3

Loading...

Loading...