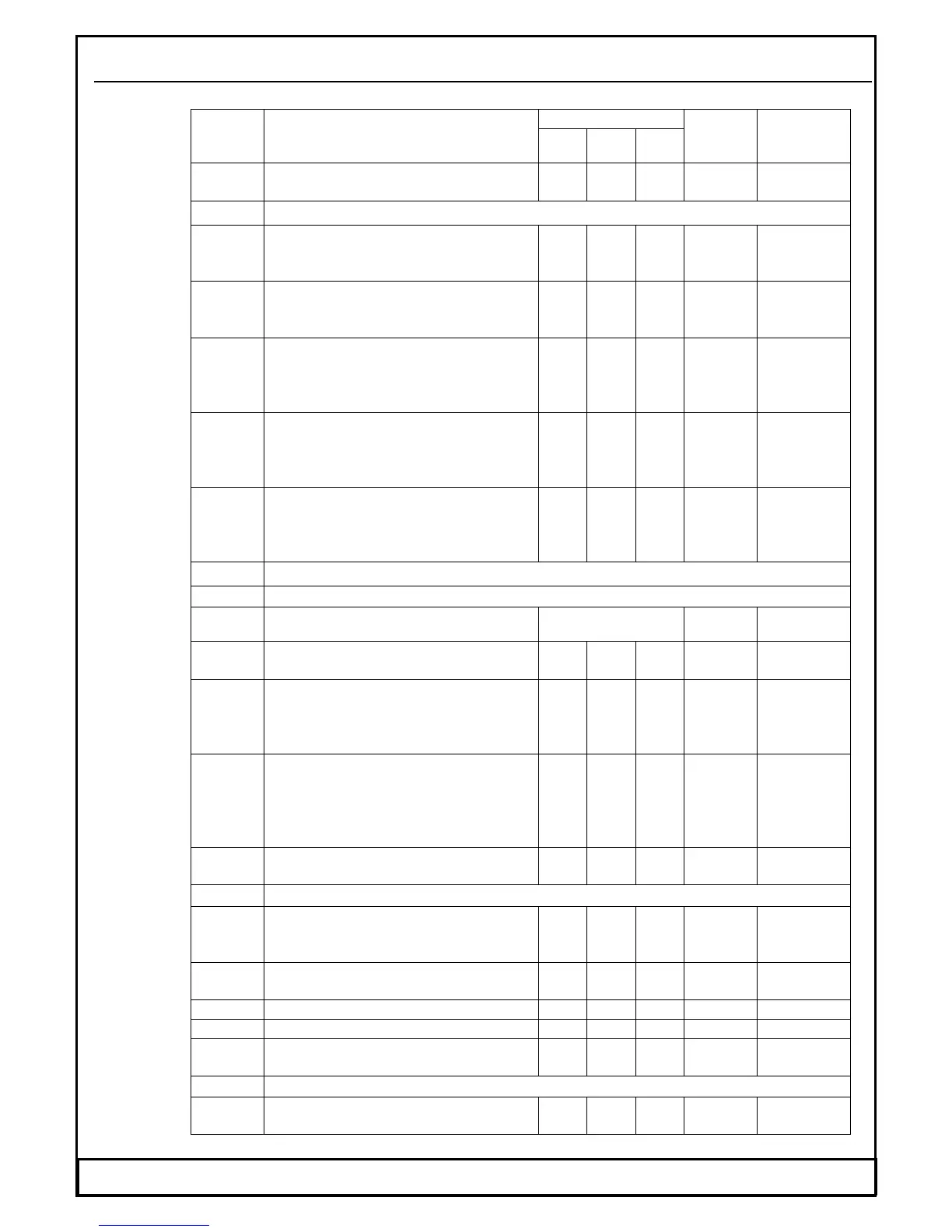

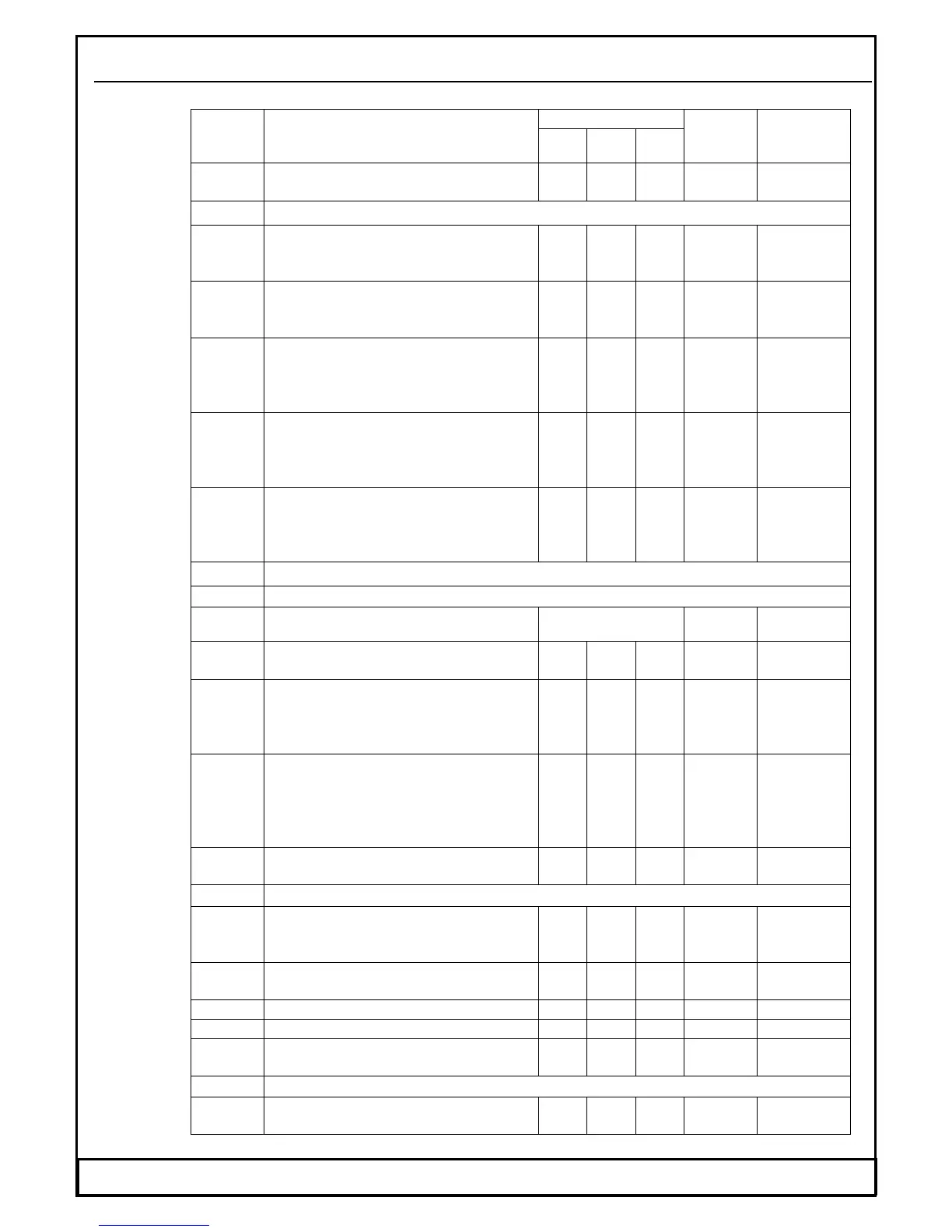

TECHNICAL DESCRIPTION, OPERATING, MAINTENANCE AND REPAIR MANUAL

Inspection after Event Event description

first

25 hr

every

50 hr

every

100hr

Carried

out by:

Inspected

by:

4.1.9 Lubricate according to the Lubrication

Chart

*

5. MAIN LANDING GEAR

5.1 Visually check of the leg for

delaminations, damages, attachment,

bolts security

* * *

5.2 Visually check laminated fairing

(mudguard) condition-repair found

damages and cracks

* * *

5.3 Check tyres for condition, cuts, uneven

or excessive wear and slippage-replace

if need be. Check pressure – inflate at

required pressure ( see Flight Manual )

* * *

5.4 Visually check condition of the pads-

steady and symmetry abrasion of the

pads-replace a pad if need be The same

is valid for the brake disc.

* *

5.5 Visually check disc for cracks,

permanent deformation – replace if need

be. Check condition of bearings, wheel

free rotation, play

* *

6.

LIFTING SURFACE

6.1 Wing

6.1.1

Wing disassembly, Check of the bushing,

root of beam and root rib

After 200 flight hours

or once a year

6.1.2 Visually check of the wing surface for

damages, delaminations, recesses

* * *

6.1.3 Check of the surface for finding out of

the delaminations of the sandwich.

Contact aeroplane manufacturer if are

found larger areas of the delaminations.

*

6.1.4 Check plays of wing suspensions . Move

the wing tip upward-downward,

frontward-rearward. Contact aeroplane

manufacturer if the motions are greater

than 5 mm

* *

6.1.5 Check pitotstatic tube attachment at the

right wing

* * *

6.2 Aileron

6.2.1 Visually check of the aileron surface for

damages, delaminations and paint

damages

* * *

6.2.2 Check free movement, aileron hinge and

plays

* * *

6.2.3 Check security of control rod ends * * *

6.2.4 Lubricate the bearings *

6.2.5 Check control-surface weight balance

attachment

* * *

6.3 Flap

6.3.1 Visually check of the flap surface for

damages, delaminations

* * *

Date: 20.10.2008, Rev3 WT-9 Dynamic Section 3 Page 3 - 8

Loading...

Loading...