HI ROLLER - BELT CONVEYORS 4. APPLICATION DESIGN CONSIDERATIONS

HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE 4.1. PRODUCT/CAPACITY CONSIDERATIONS

P115506 R3 27

4. Application Design

Considerations

This section is included to help you plan for the set-up and installation of your

belt conveyor. Please review before beginning installation.

4.1. PRODUCT/CAPACITY CONSIDERATIONS

• Multiple Products: Make sure that the conveyor is designed and installed to

handle all types and sizes of the materials you require.

• Bulk Density: pounds per cubic foot, pounds per bushels, metric tons per

cubic meter, kg/cubic meter, etc.

• Abrasive/Corrosive/Sticky/Moist/Hot/Oily Materials: Design considera-

tions must be reviewed with Hi Roller's engineering department.

• Capacity: Inclined conveyors of any type will not convey the same amount of

material as a flat horizontal conveyor. Hi Roller's engineering department will

calculate the capacity of a specific application.

• Belt Speed: The minimum for proper reloading is 350 fpm for granular mate-

rials, and 400 fpm for powders/fine materials/meals.

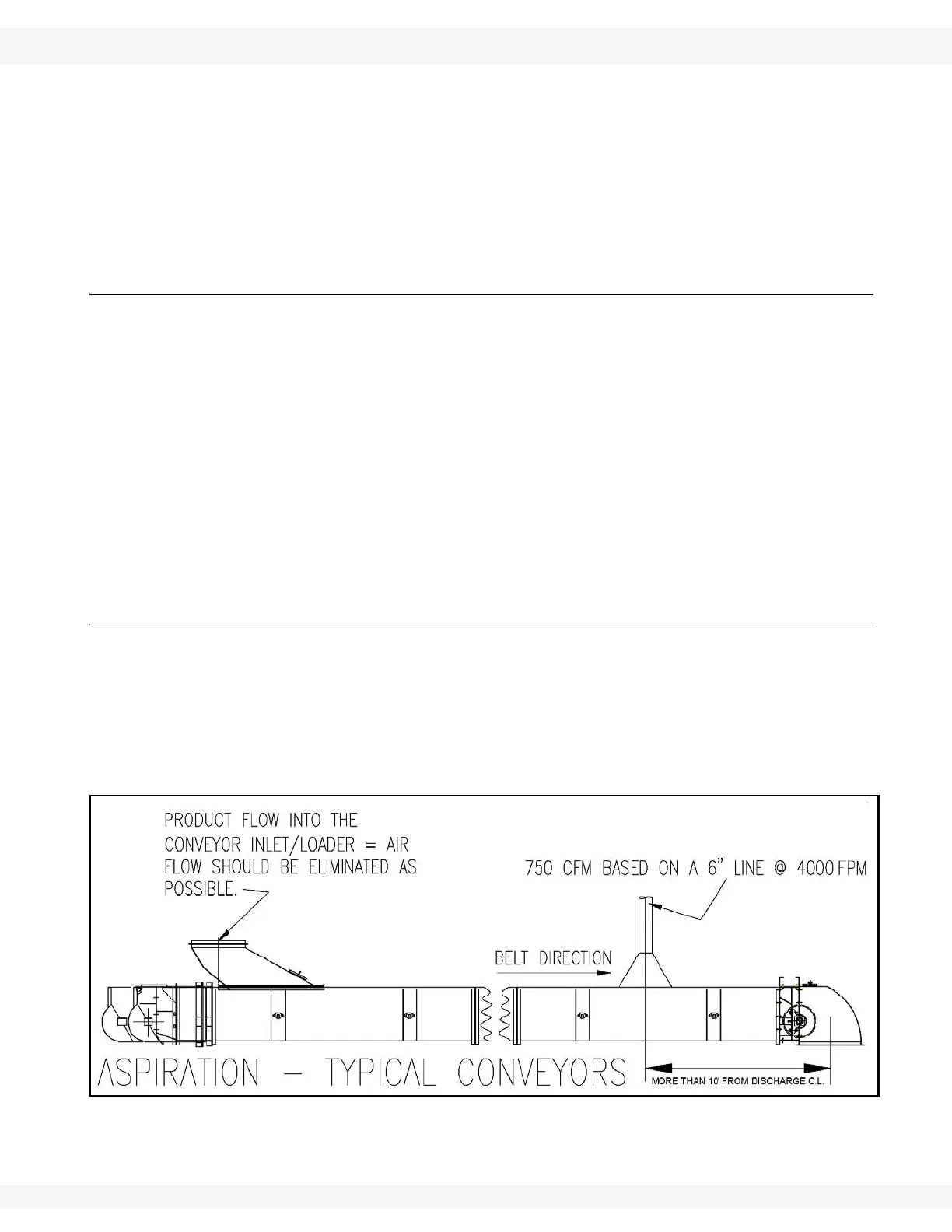

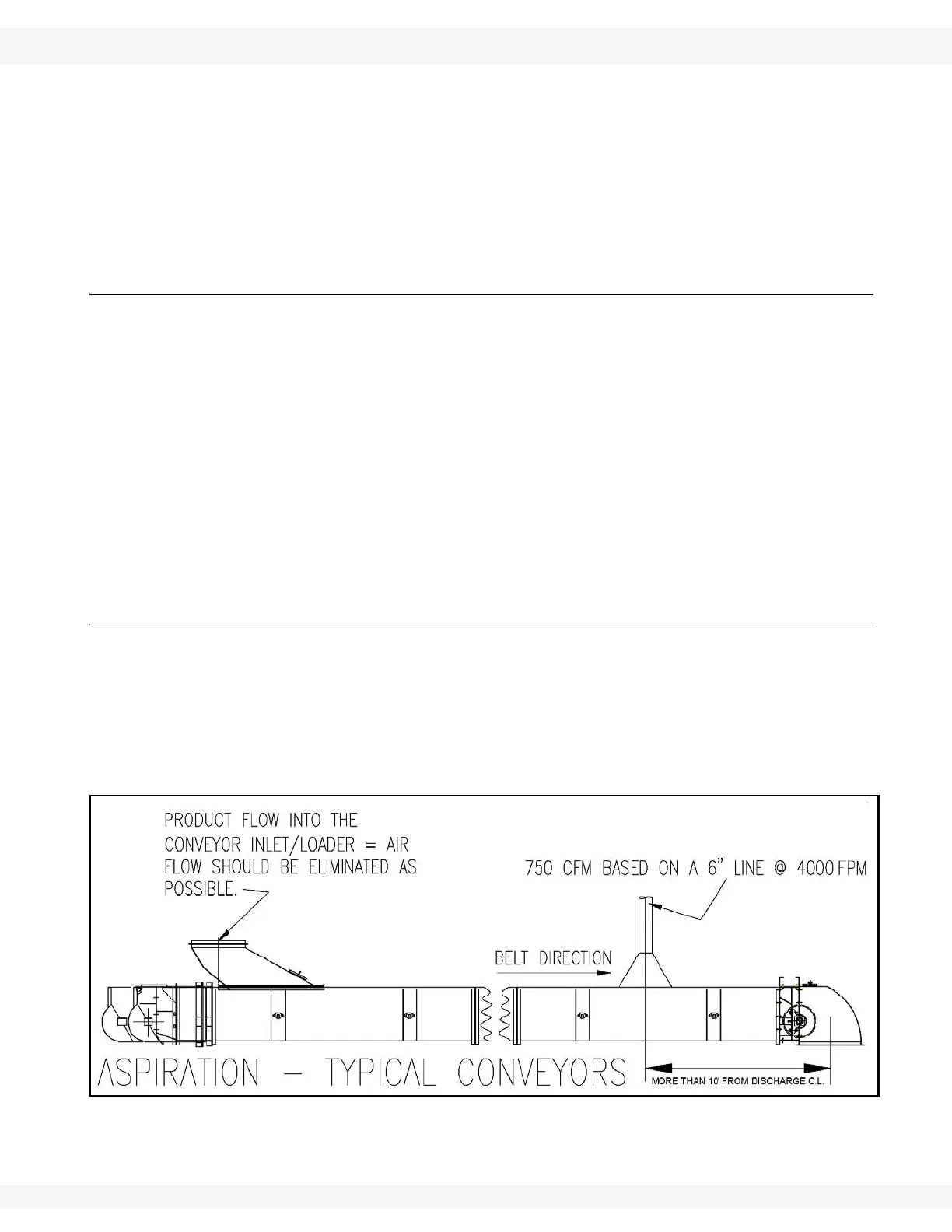

4.1.1. ASPIRATION

Aspiration is designed to remove dust and not convey material.

GENERAL - DRY AMBIENT MATERIAL

• A 750 cfm system based on a 6” line at 4000 fpm is required to keep the lines

clear. A pickup hood is also required so material is not picked up by the air

(Figure 4.1).

Figure 4.1

Loading...

Loading...