5. INSTALLATION HI ROLLER - BELT CONVEYORS

5.10. FINAL CHECKLIST HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE

74 P115506 R3

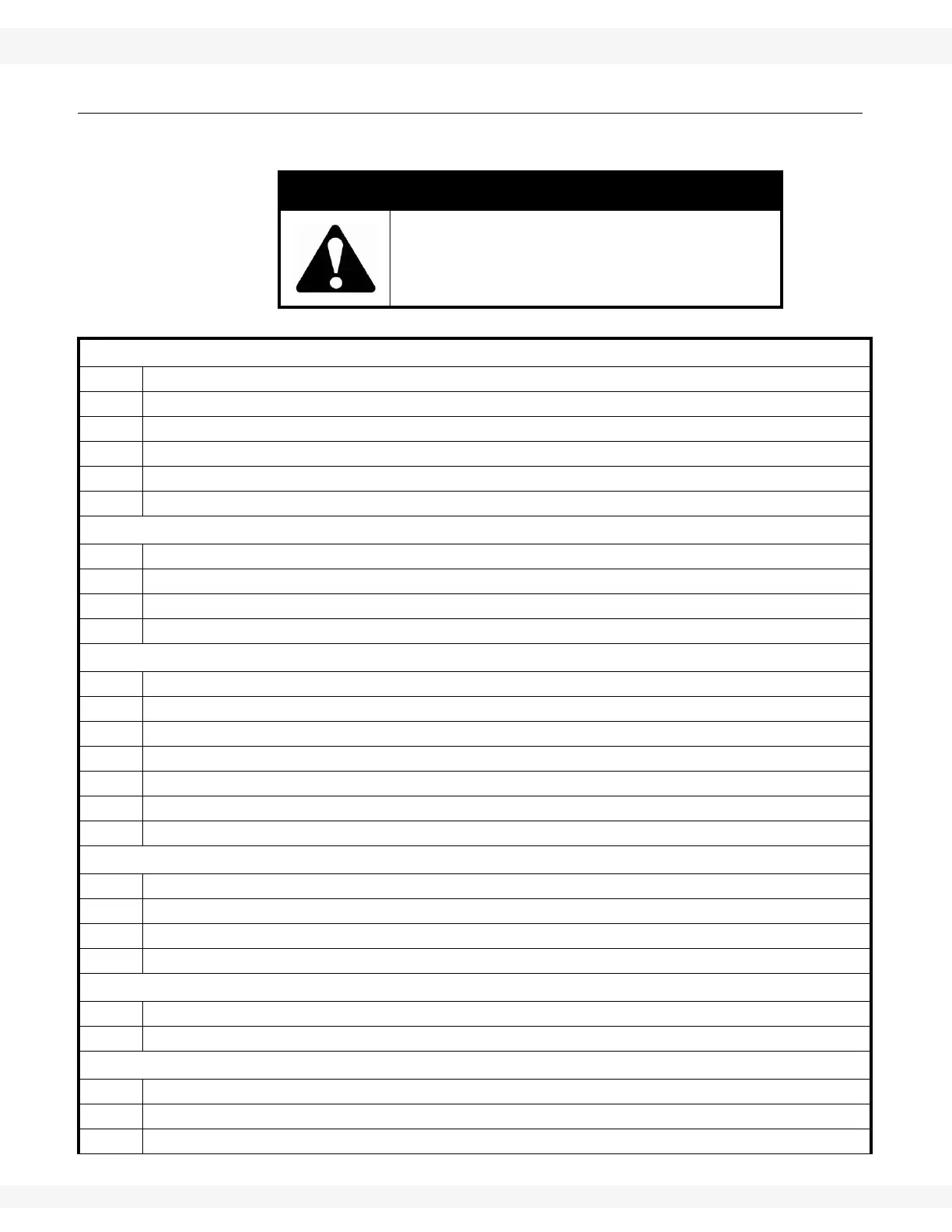

5.10. FINAL CHECKLIST

Complete final checklist and file with management.

CAUTION

Complete the final inspection checklist before

start-up to ensure proper and safe operation

of the conveyor.

Head Section

Properly installed w/ clearances around head section, bearings, motor, drive, etc.

Head sections properly mounted and secured. All connections bolted, never welded.

Head pulley securely locked on the head shaft.

Head shaft bearings securely locked on the head shaft.

Drive components securely locked in place and properly aligned.

Belt, chain, couplings, cooling fan, and other guards properly installed.

Discharge Overshot

Properly installed with clearances all around for removal and servicing.

All bolted flanges sealed with silicone sealant.

Lining material installed where required.

Pressure plug switch installed and tested.

Trunking

Head, tail, and intermediate trunking section installed in numerical order.

Sections rechecked to ensure a +/- 1/8" tolerance for the full length of the conveyor.

Sections installed level (not as critical as straightness of trunking).

Properly installed; clearances on bottom to remove conveyor bottoms for servicing.

Properly installed; clearances on both sides to remove/service idlers and bearings.

Supports installed at least every 20’ of the length of the conveyor.

Support legs/hangers bolted to trunking vertical/bottom flanges (never welded).

Tail Section

Properly installed; clearances around the tail section, bearings, monitors, etc.

Tail section properly mounted and secured. All connections bolted, never welded.

Tail pulley securely locked on the tail shaft.

Tail shaft bearings securely locked on the tail shaft.

V-Plow

Adjusted for proper clearance under v-plow blade to belt.

Checked during operation that the splice protector / wiper cleats do not hit the v-plow.

Loaders/Inlets

Properly designed and installed inlets/loaders.

Inlets/loaders installed so backplate directs material forward in the direction of the belt.

Material directed to flow down the loader backplate.

Loading...

Loading...