5. INSTALLATION HI ROLLER - BELT CONVEYORS

5.3. INLET/LOADER INSTALLATION HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE

40 P115506 R3

Figure 5.9

4. The installation is the reverse of the removal. The security bolt must be

removed by a mechanical technician.

5.3. INLET/LOADER INSTALLATION

The loader must be placed on the conveyor trunking so it will load in the same

direction as the belt travels. The loading point of a belt conveyor is the critical

point. Here, the conveyor belt receives major abrasion and almost all of its

impact. Ideally, material will pass from spout to belt at the same speed and

direction of travel as the belt, with a minimum amount of impact and centered on

the belt.

Off-center loading is harmful to the belt, idlers, and shafting, and will cause belt

alignment problems.

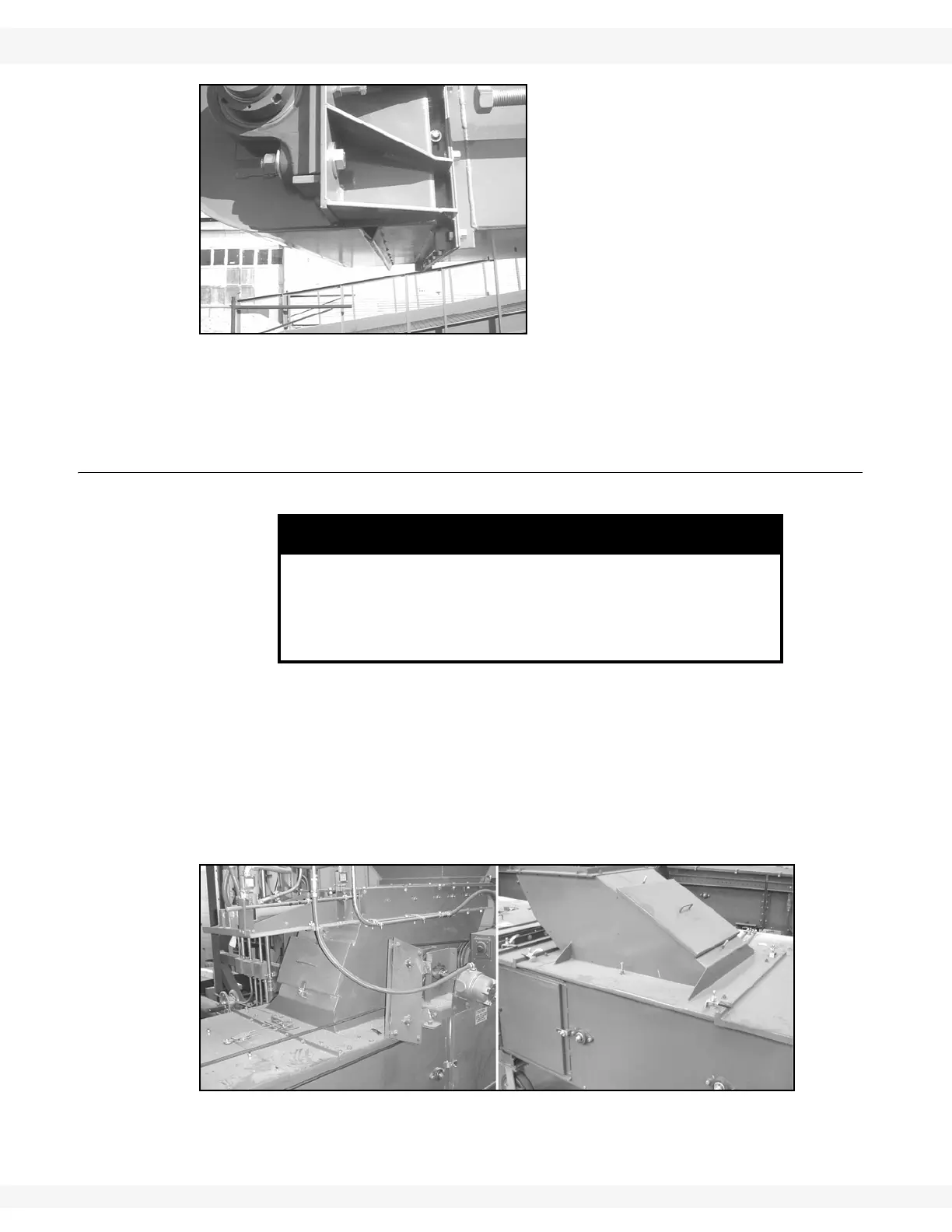

Figure 5.10 Standard Inlets - Flat Top w/ Matching Flange and Control Gate

NOTICE

Loaders/inlets must be installed properly to achieve proper

loading of the belt.

Improper loading can cause damage to the conveyor

components.

Loading...

Loading...