HI ROLLER - BELT CONVEYORS 7. MAINTENANCE

HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE 7.1. MAINTENANCE SCHEDULES

P115506 R3 83

7. Maintenance

7.1. MAINTENANCE SCHEDULES

Important: Regular inspections and preventative maintenance are very important to the

proper operation of a Hi Roller Conveyor.

The preventative maintenance schedule below (PM) is only an example. It is

impossible to determine an exact PM schedule for all applications. Each appli-

cation needs its own PM schedule.

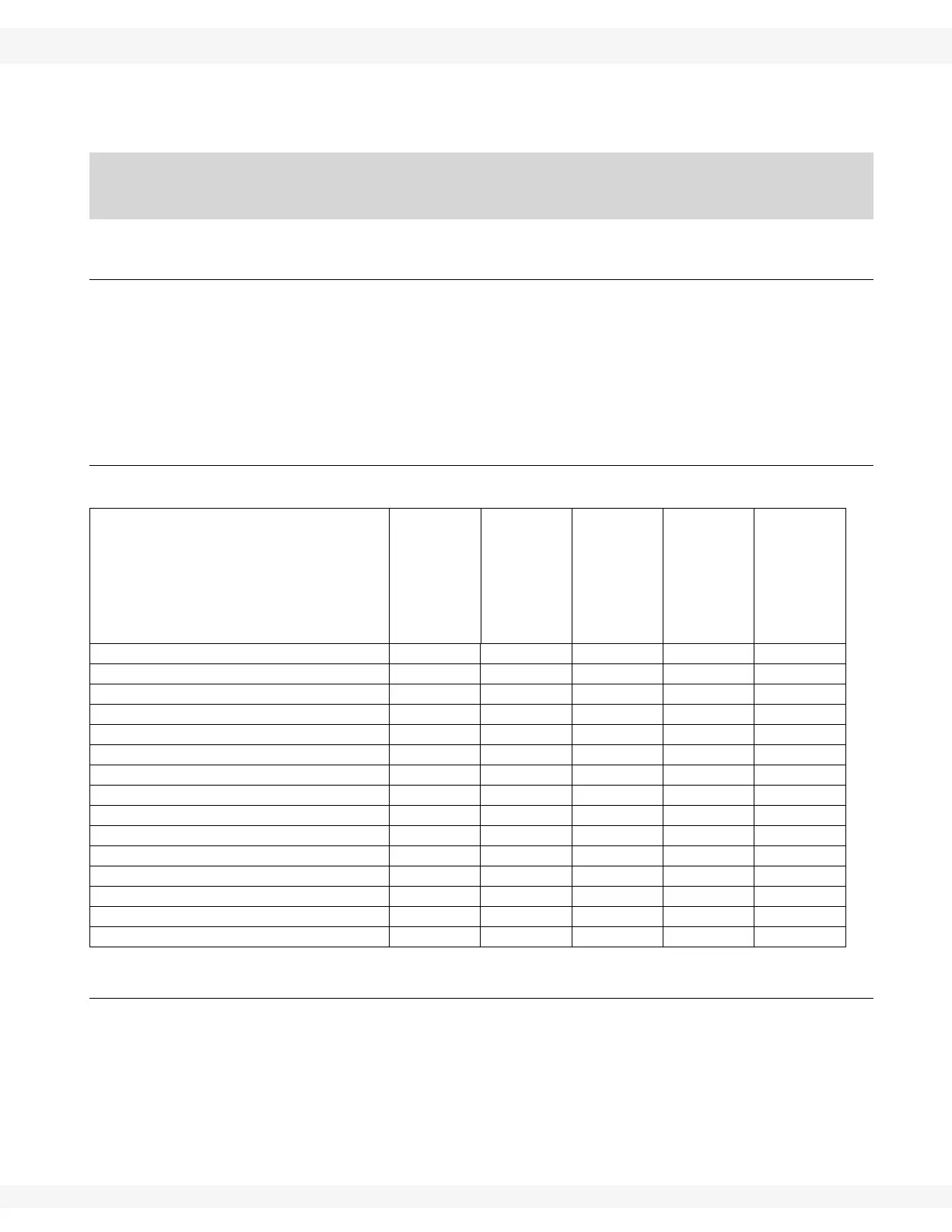

7.1.1. BASIC PREVENTATIVE MAINTENANCE SCHEDULE

7.1.2. LUBRICATION SCHEDULE

Important: Drive/reducers are shipped dry and must be filled with the proper oil/lubricant as

specified by the manufacturer prior to initial start-up.

Important: Bearings must be properly lubricated and checked weekly to ensure proper

operation.

Hi Roller Conveyors are installed in many different types of applications. A lubri-

cation schedule must be developed for each application.

WARNING Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

Table 7.1

Item

Daily

Weekly

Monthly

6 months

(3 w/ heavy usage

Seasonally

Belt tension (Section 5.4.5.)

Belt tracking (Section 7.2.)

Cleaning system

Reload paddles/flippers

Adjust belt plow (Section 5.6.)

Aspiration system (Section 4.1.1.)

Loading/spillage/bearings

Bearings

Bottom return liner

Head pulley slippage

Discharge

Set screws

Splice protector / wiper cleats

Motor and Drive

Hazard monitors

Loading...

Loading...