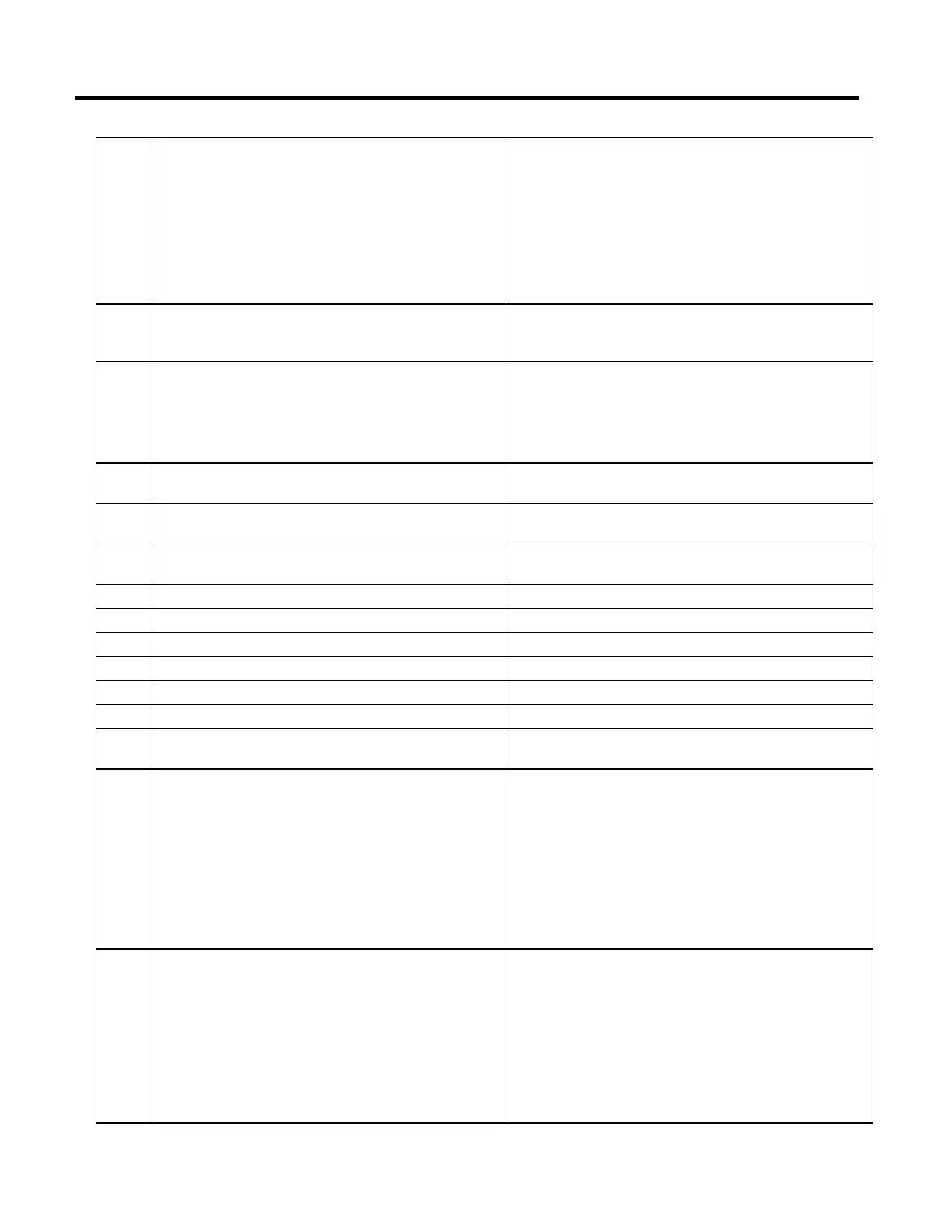

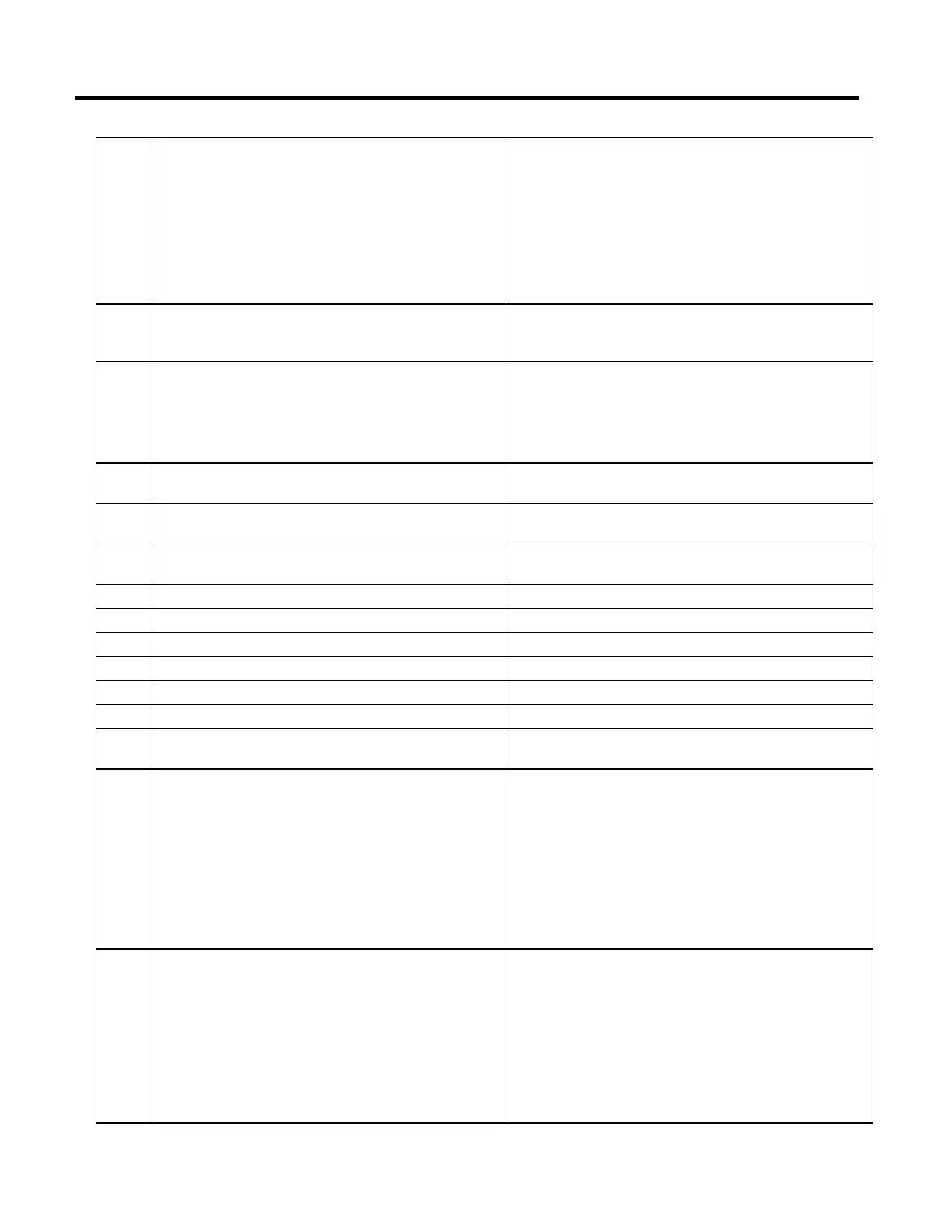

Motion Error Codes, faults, and attributes

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 565

132 Operands of MCS should be set as follows. Otherwise the instruction will error.

1. If Change Decel is set to Yes, then Decel Units must be % of Maximum.

Units per Sec2 is not acceptable because different decel value is needed for

Cartesian and orientation axes.

2. Change Decel Jerk must be set to Yes. Setting it to No is not acceptable

because different jerk value is needed for Cartesian and orientation axes.

3. Decel Jerk Units must be programmed in % of time. Units per Sec3 and % of

Maximum, are not acceptable because different value is needed for Cartesian

and orientation axes.

MCS Units conflict.

135 If MCPM speed, accel or decel units are programmed in % of max and the

associated master driven MDCC instruction nominal master velocity is set to zero,

the instruction will error.

MCPM zero nominal master velocity.

136 There are two possible situations that can result in this conflict:

• MCPM continuous path (CP) move is programmed with robot configuration

parameter different from the current robot configuration.

• If there is already some CP move in the queue and the new programmed

move robot configuration is different from the move in queue.

MCPM robot configuration conflict.

137 The robot configuration parameter for the MCTPO instruction is not valid for this

Robot geometry.

Invalid robot configuration.

138 Refer to the extended error codes in the online help for the MCPM instruction for

details related to this error code.

MCPM path data invalid value.

139 Refer to the extended error codes in the online help for the MCPM instruction for

details related to this error code.

MCPM Dynamics Data invalid value.

140 Wait until the Servo On operation is complete. Servo On in progress.

141 Wait until the Servo Off operation is complete. Servo Off in progress.

142 Wait for the Shutdown Reset operation to complete. Shutdown Reset in progress.

143 Wait for Axis Homing to complete. Home in progress.

144 Wait for the Motion redefine position operation to complete. Redefine in progress.

145 Wait for the Shutdown operation to complete. Shutdown in progress.

146 Cannot start motion if the maximum orientation deceleration for the coordinate

system is zero.

Maximum orientation deceleration is zero.

147 A orientation axis (Rx, Ry, or Rz) in the coordinate system has one of the

following:

• The conversion constant (planner feedback counts per position unit) is

greater than 20,000 value.

• The conversion constant is not an integer

• A conversion ratio between Coordination Units and Position Units is not 1:1

Refer to the online help for the instruction for extended error code definitions. It

identifies the orientation axis.

Invalid orientation scaling constant.

148 The MCTO or MCTPO instruction reports this error when the Orientation offset is

not valid when:

• Delta Robot Geometry is J1J2J6 or J1J2J3J6 and Workframe offset for Rx or Ry

is not 0 or the Toolframe offset for Rx or Ry is not 0

• Delta Robot Geometry is J1J2J3J4J5 and Workframe offset for Rx or Ry is not 0

or the Toolframe offset for Rx or Rz is not 0

Refer to the online help for the instruction for extended error code definitions. It

identifies the orientation axis.

MCTO or MCTPO orientation offset is not zero.

Loading...

Loading...