Motion Error Codes, faults, and attributes

572 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

AttributeErrorCode INT GSV G11/Status

Returns the appropriate CIP error code when an Axis Configuration fault occurs. It is not reset to zero until

the motion module is reconfigured.

AttributeErrorID INT GSV G11/Status

Retains the identification associated with the error code returned when an Axis Configuration fault

occurred. The module must be reconfigured to reset this attribute to zero.

AuxFeedbackConfiguration INT GSV G10/Configuration

Maps directly to the SERCOS IDN, and is automatically set based on the current Drive Polarity Settings. All

command bits are set according to the current Feedback Type value.

AuxFeedbackRatio REAL GSV G10/Configuration

Represents the quantitative relationship between the auxiliary feedback device and the motor. It is used

in range limit and default calculations during configuration, based on the selected motor's specifications.

It is also used by the drive when running the dual feedback loop configuration.

AuxFeedbackResolution DINT GSV G10/Configuration

Provides the A-B drive with the resolution of the associated feedback device in cycles. It also provides the

Logix controller and drive with critical information to compute conversion constants used in converting

drive units to feedback counts.

AuxFeedbackType INT GSV G10/Configuration

Provides the A-B drive with specific device configuration information for the auxiliary feedback device.

AuxPositionFeedback REAL GSV G11/Status

The current value of the position feedback coming from the auxiliary feedback input.

AverageVelocity REAL GSV G1/Status

The current speed of an axis, as calculated by averaging the actual velocity of the axis over the configured

Average Velocity Timebase for the axis. It is a signed value to indicate the direction in which the axis is

moving.

AverageVelocityTimebase REAL GSV G1/Configuration

Specifies the desired time in seconds for use in calculating the Average Velocity of the axis. The values

should be large enough to filter out the small changes in velocity which would otherwise result in a noisy

velocity value, yet small enough to track significant changes in axis velocity. A value between 0.25 and

0.50 seconds works for most applications.

AxisConfigurationState SINT GSV G1/Interface

Used for debugging purposes to indicate the present location of the axis in the axis configuration

state-machine. Consumed and virtual axes use this attribute also.

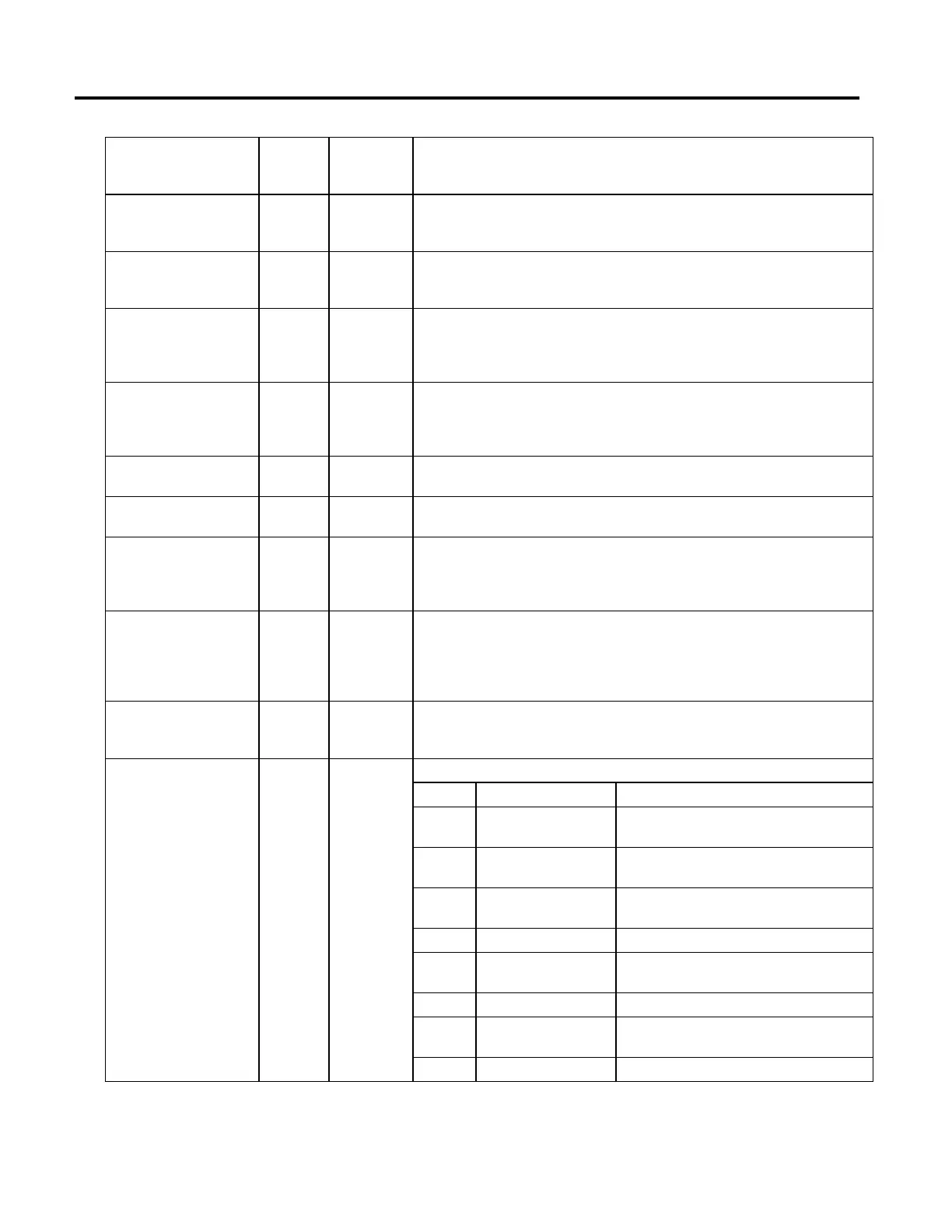

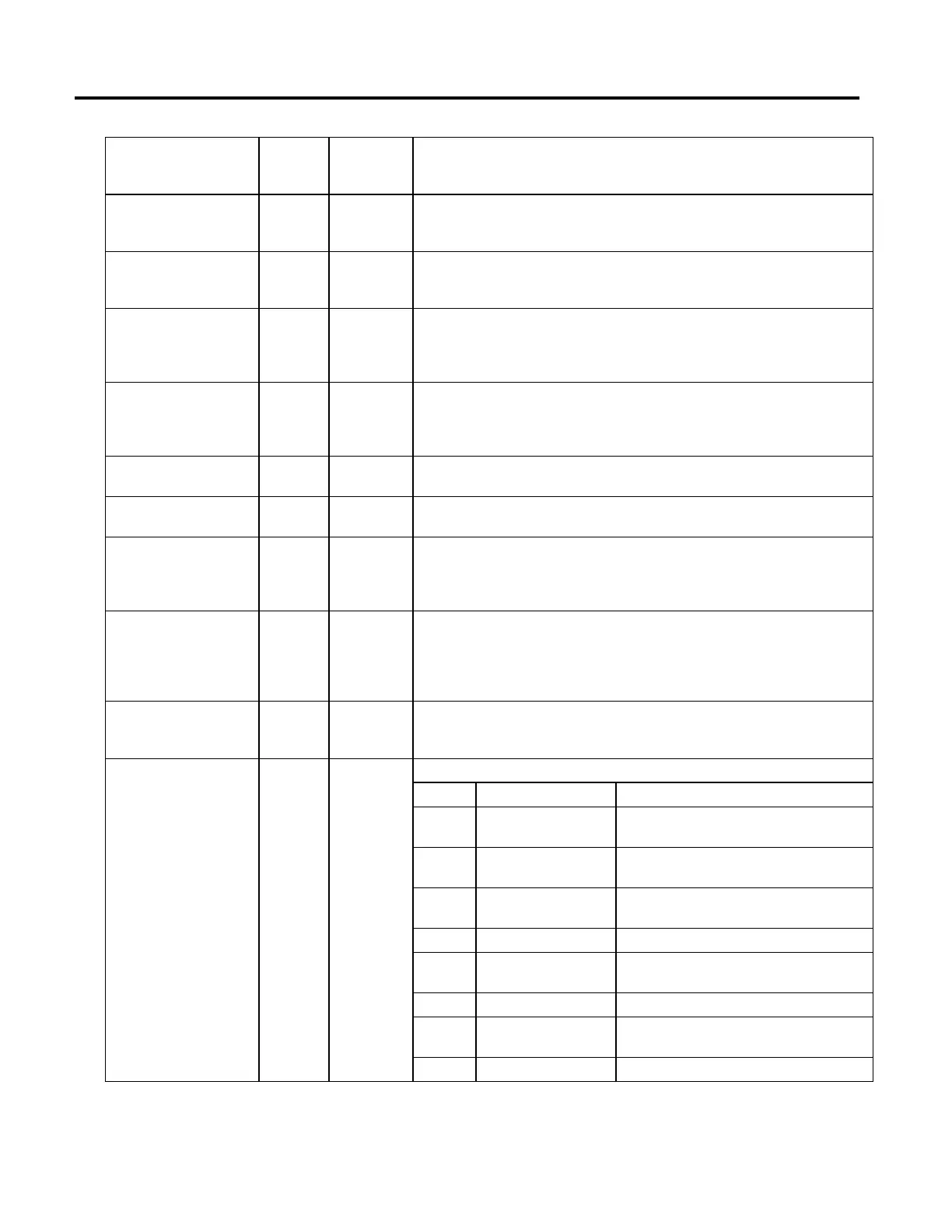

AxisControlBits DINT GSV G11/Status

Bit Bit Name Meaning

0 Abort Process Request

When set, the servo module/drive disables any active

tuning or testing process.

1 Shutdown Request

When set, the servo module forces the axis/drive into the

shutdown state.

2

Zero DAC Request (Servo)

Reserved (Servo Drive)

When set, the servo module forces the DAC output for the

axis to zero volts.

3 Abort Home Request When set, any homing procedures are canceled.

4 Abort Event Request

When set, any active watch or registration procedures are

canceled.

5-14 Reserved

15 Change Cmd Reference

This bit is set when the Logix controller switches to a new

position coordinate system for command position.

16-31 Reserved

Loading...

Loading...