Process Control Instructions

168 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

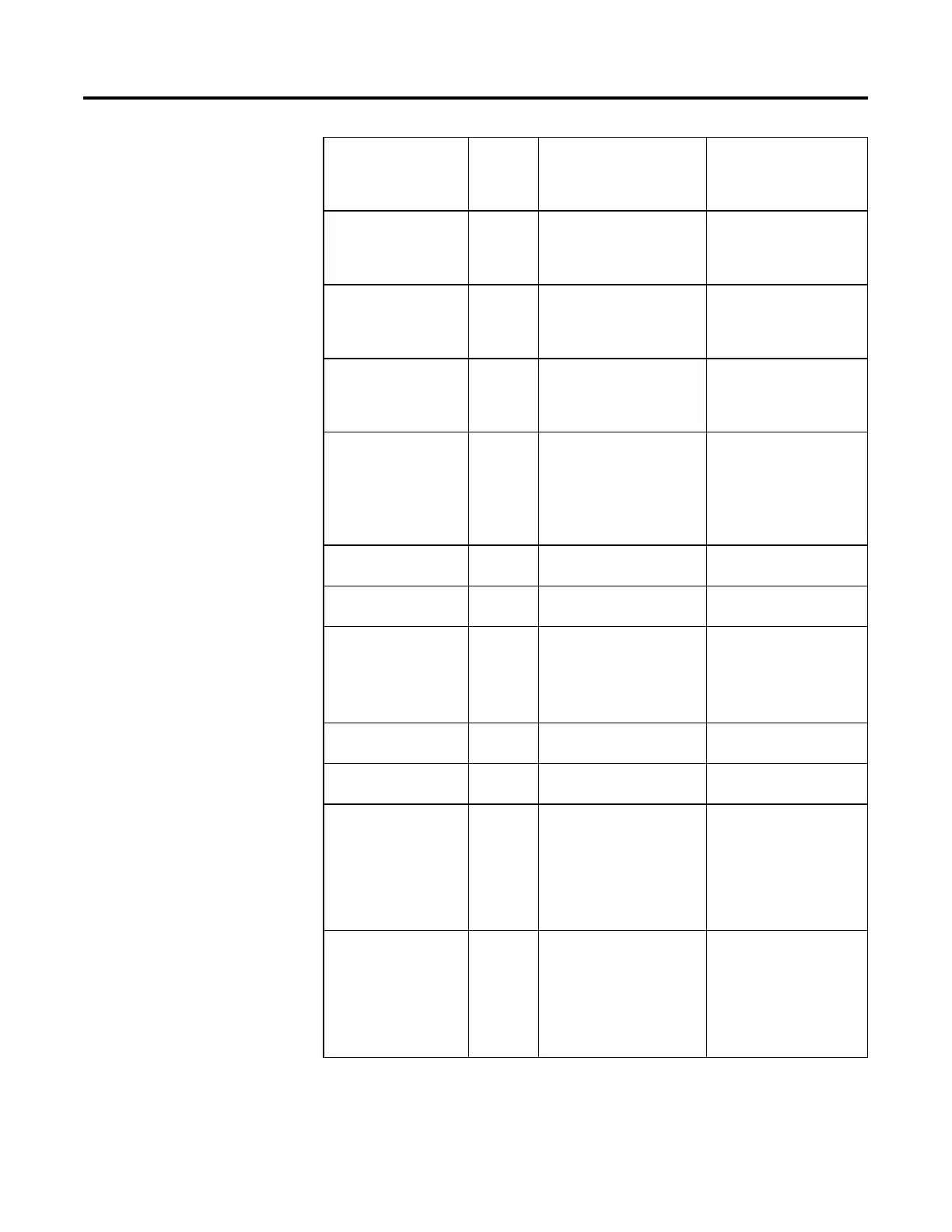

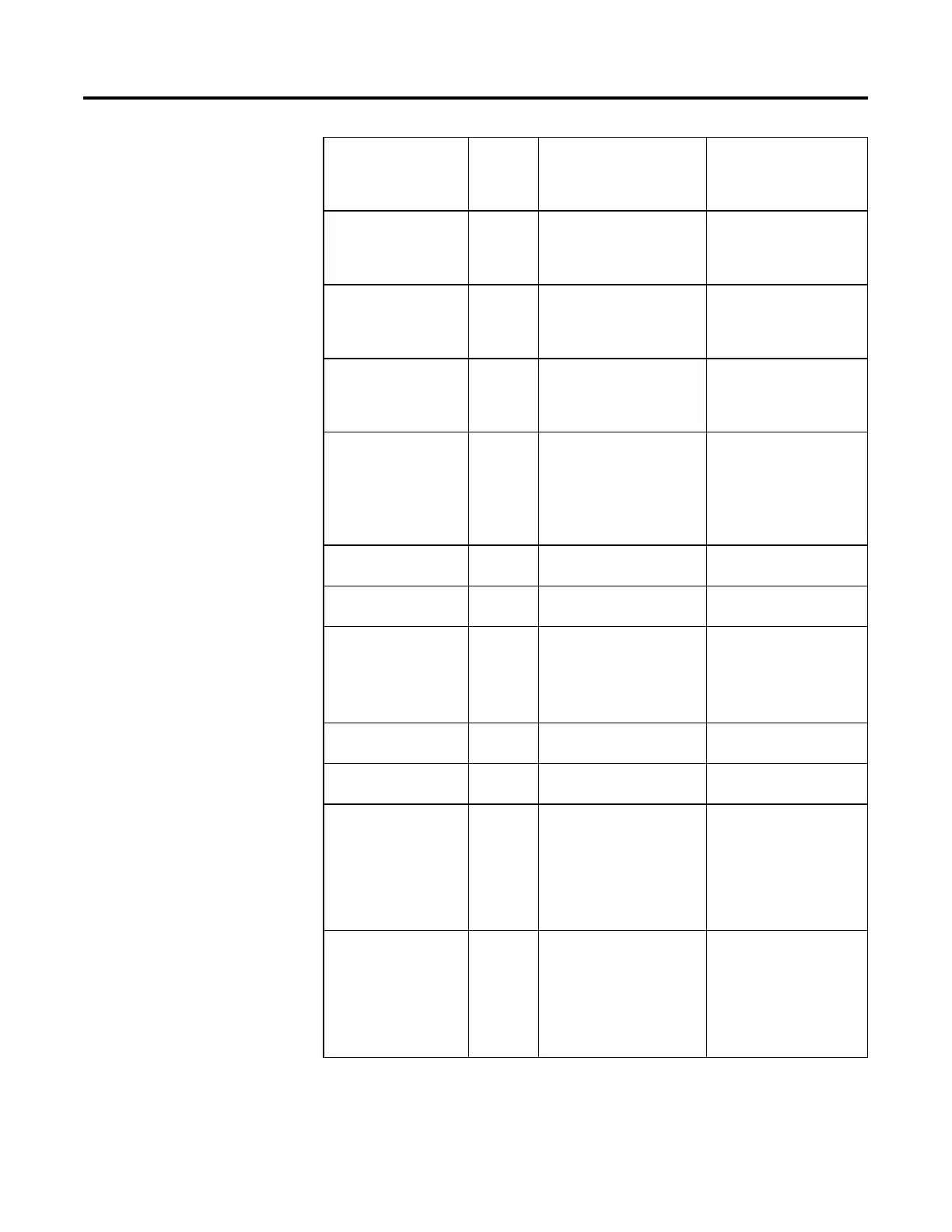

CV1ROCNegAlarm BOOL CV1 rate of change alarm indicator.

TRUE when the calculated rate of

change for CV1 exceeds

CV1ROCNegLimit.

CV2ROCNegAlarm BOOL CV2 rate of change alarm indicator.

TRUE when the calculated rate of

change for CV2 exceeds

CV2ROCNegLimit.

CV3ROCNegAlarm BOOL CV3 rate of change alarm indicator.

TRUE when the calculated rate of

change for CV3 exceeds

CV3ROCNegLimit.

SP REAL Current setpoint value. The value of

SP is used to control CV when in the

Auto or the PV Tracking mode,

scaled in PV units.

SPPercent REAL The value of SP expressed in percent

of span of PV.

SPPercent = ((SP − PVEUMin ) *

100) / PVSpan.

PV Span calculation: PVSpan =

( PVEUMax − PVEUMin )

SPHAlarm BOOL SP high alarm indicator. TRUE when

the SP ≥ SPHLimit.

SPLAlarm BOOL SP low alarm indicator. TRUE when

the SP ≤ SPLLimit.

PVPercent REAL PV expressed in percent of span.

PVPercent = (( PV − PVEUMin ) *

100) / PVSpan

PV Span calculation: PVSpan =

( PVEUMax − PVEUMin )

E REAL Process error. Difference between SP

and PV, scaled in PV units.

EPercent REAL The error expressed as a percent of

span.

CV1WindupHOut BOOL CV1 Windup high indicator.

TRUE when either a SP high or CV1

high/low limit has been reached.

This signal will typically be used by

the WindupHIn input to limit the

windup of the CV1 output on a

primary loop.

CV2WindupHOut BOOL CV2 Windup high indicator.

TRUE when either a SP high or CV2

high/low limit has been reached.

This signal will typically be used by

the WindupHIn input to limit the

windup of the CV2 output on a

primary loop.

Loading...

Loading...