296 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Chapter 14 Status, Faults, and Alarms

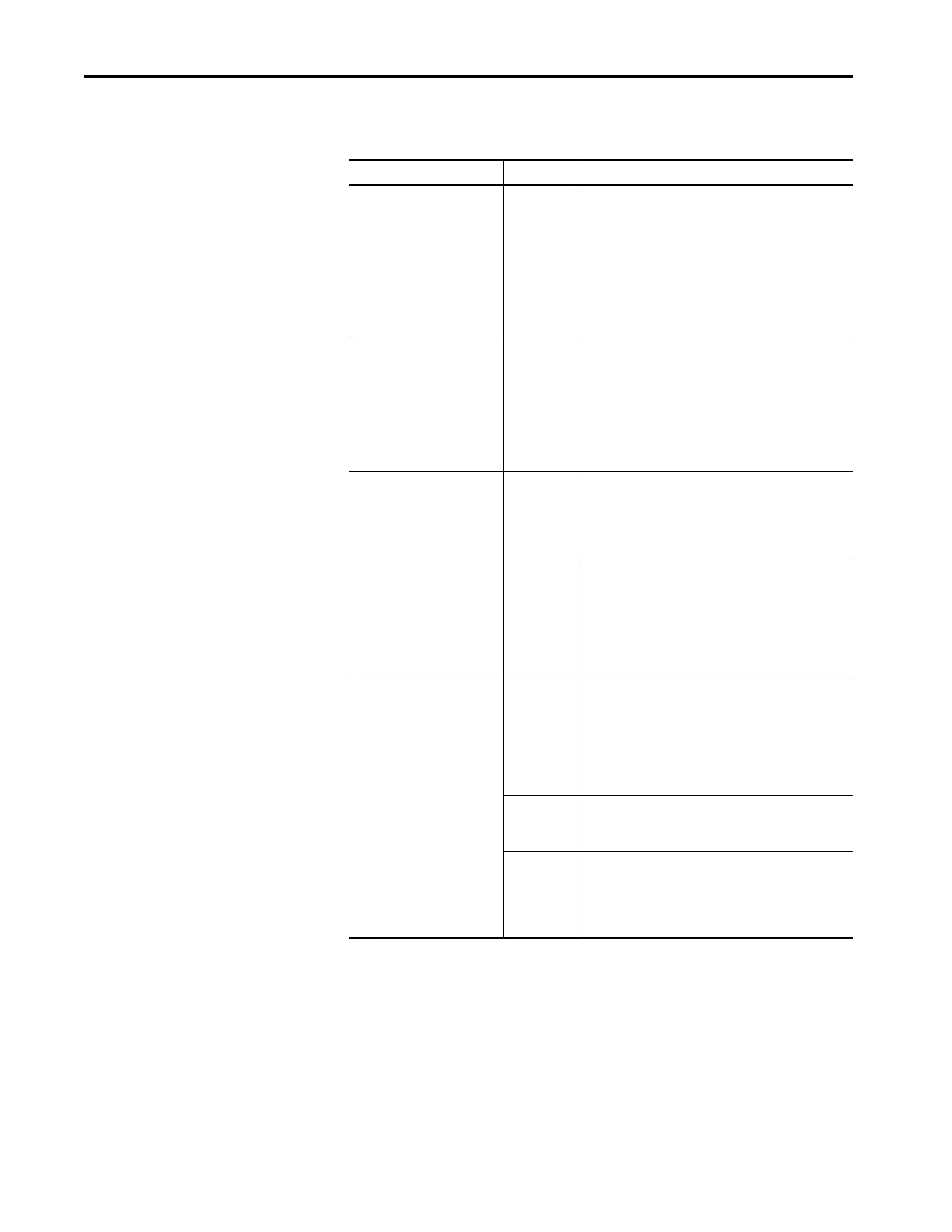

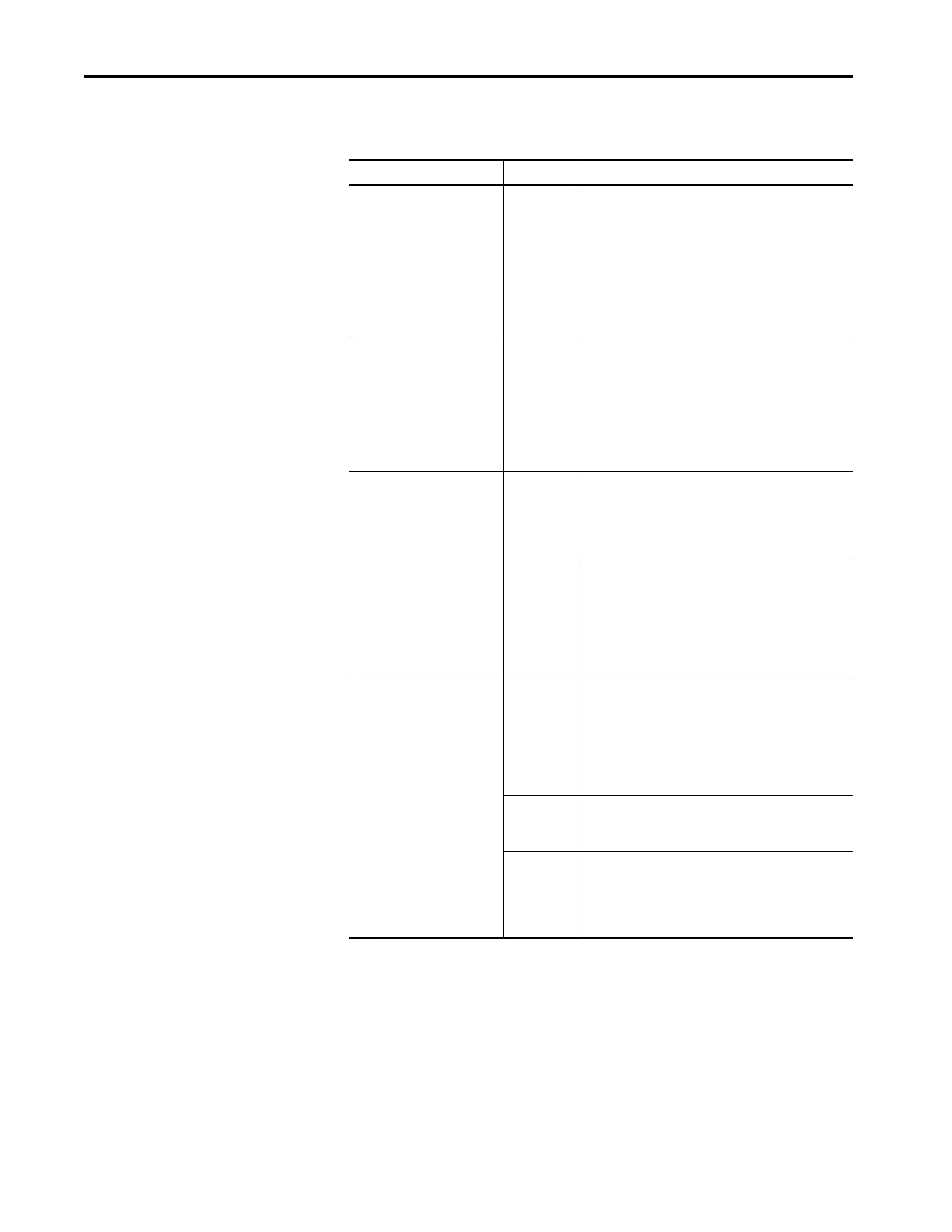

Table 66 - Action Tasks and Related Faults

Task Choose Description

Shut down the axis and let it

coast to a stop.

Shutdown Shutdown is the most severe action. Use it for faults that could

endanger the machine or the operator if you do not remove

power quickly and completely.

A fault happens when the following occurs:

• Axis servo action is disabled

• Servo amplifier output is zeroed

• Appropriate drive enable output is deactivated

• OK contact of the servo module opens. Use this contact to

open the E-stop string to the drive power supply

Stop the axis and let the drive

stop the axis where you use the

Stopping Action attribute to

configure how to stop the drive.

Disable A fault happens when the following occurs:

• Axis servo action is disabled

• Servo amplifier output is zeroed

• Appropriate drive enable output is deactivated

• Drive switches to local servo loop control and the axis are

slowed to a stop using the Stopping Torque

• The servo action and the power structure are disabled if the

axis doesn’t stop in the stopping time

Leave the servo loop on and stop

the axis at its Maximum

Deceleration rate.

Stop Planner Use this fault action for less severe faults. It is the gentlest way

to stop. Once the axis stops, you must clear the fault before

you can move the axis. The exception is Hardware Overtravel

and Software Overtravel faults, where you can jog or move the

axis off the limit.

A fault happens when the following occurs:

• Axis slows to a stop at the Maximum Deceleration Rate

without disabling servo action or the servo module Drive

Enable output

• Control of the servo loop of the drive is maintained

• Axis slows to a stop at the Maximum Deceleration rate

without disabling the drive

Write your own application code

to handle the fault.

Fault Status

Only

Use this fault action only when the standard fault actions are

not appropriate. With this fault action, you must write code to

handle the motion faults. For Stop Motion or Status Only, the

drive must stay enabled for the controller to continue to

control the axis. Select Status Only to let motion continue only

if the drive itself is still enabled and tracking the command

reference.

Ignore Ignore instructs the device to ignore the exception condition.

For some exceptions that are fundamental to the operation of

the axis, it is not possible to Ignore the condition.

Alarm Alarm action instructs the device to set the associated bit in

the Axis Alarm word, but does not otherwise affect axis

behavior. For some exceptions that are fundamental to the

operation of the device, it is not possible to select this action or

any other action that leaves device operation unaffected.

Loading...

Loading...