343-3512A (03/13)

13 of 27

Optimize

IMPORTANT

The primary uses of support legs are at 90° panel junctions and/or to support adjoining worksurfaces.

When used to support a single worksurface, the worksurface grommet hole will be partially blocked.

If full access of grommet hole is required, replace support leg with a cantilever support bracket.

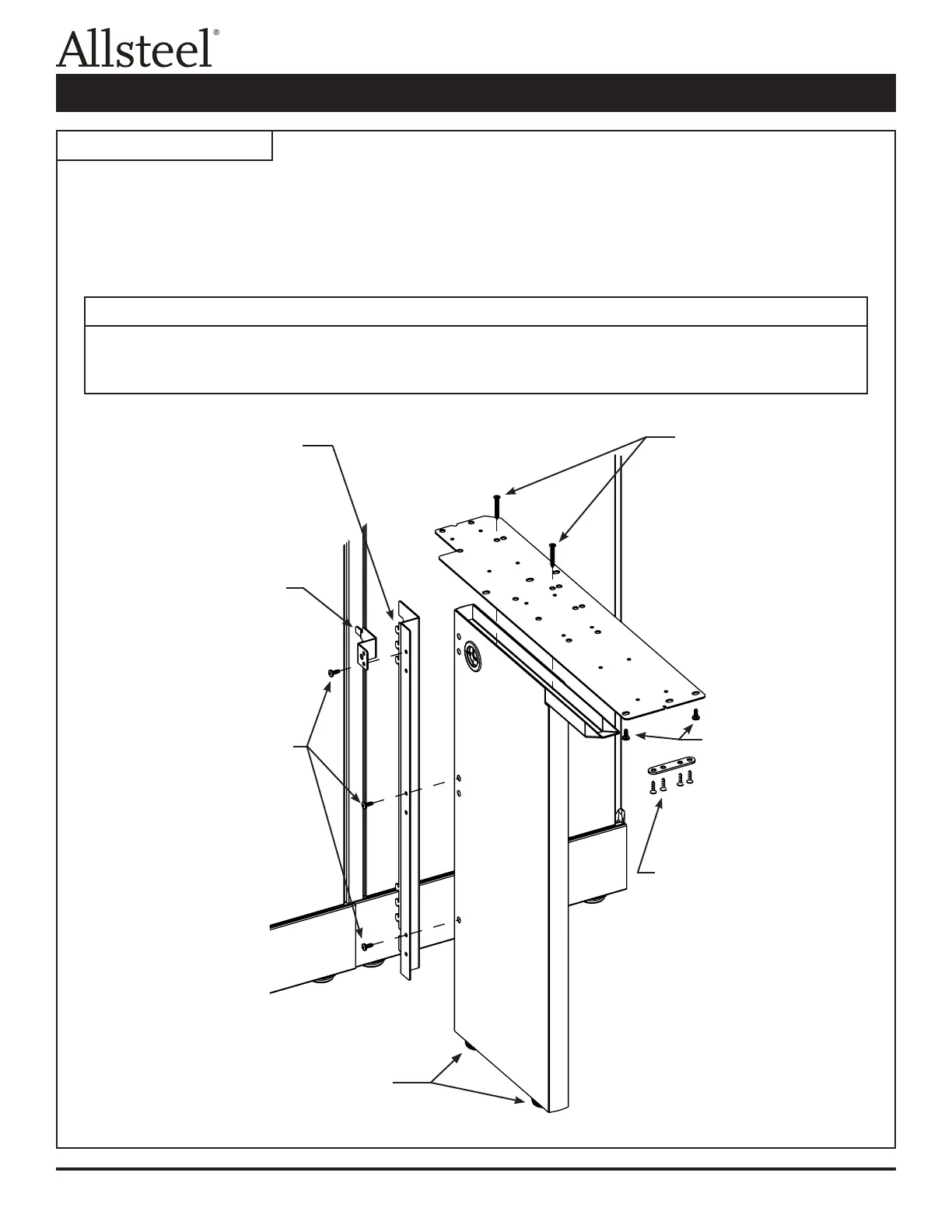

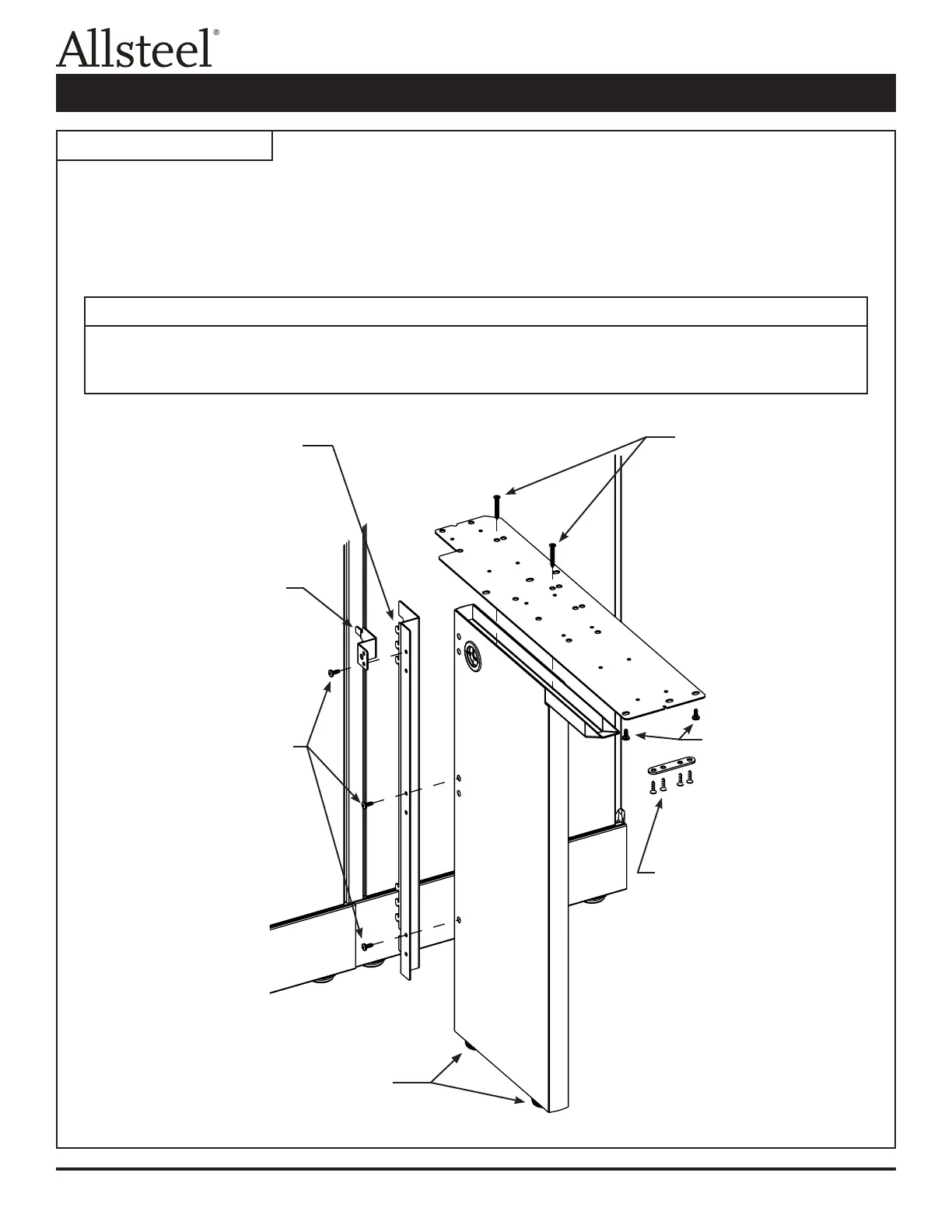

Illustration 2: Support Leg

Step 1 - Insert panel attachment

bracket tabs into panel

slots and lift bracket,

hooking tabs behind panel

frame.

Step 2 - Insert anti-dislodgement

bracket into panel slot

and align bottom hole of

bracket with top hole of

full end panel support.

Step 3 - Install sheet metal screws

through top holes of each

pair of panel attachment

bracket holes and into top

holes of support leg.

Note: Insert color matched

hole plugs into holes

on opposite side of

support leg.

Assembly:

1. Assemble support leg, panel attachment bracket, and at bracket in a conguration where the leg is under the

largest worksurface.

2. Right-hand conguration is shown. Attach panel attachment bracket to opposite side of support leg for a left-hand

conguration. Flip at bracket over for left-hand applications.

Step 6 - Install wood

screws through

round holes in

at bracket and

into bottom of

worksurface.

Step 5 - Install two at head

sheet metal screws

through larger holes

in at bracket and

into top of support

leg.

Note: Right-hand

application shown.

Flip bracket over for

left-hand application.

Step 7 - Connect tie plate

between two

worksurfaces. Install

wood screws through

holes in tie plate and

into worksurfaces.

Step 4 - Turn leveling glides

until glides are at

against oor.

Worksurface Supports Installation

Loading...

Loading...