32

•

MN-35947

•

Rev 15

•

01/18

•

Combitherm® CT PROformance™ and CT Classic Series Installation Manual

#439 - 01/18 DUE TO ONGOING PRODUCT IMPROVEMENT, SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. WWW.ALTO-SHAAM.COM

ELECTRICAL

(NO CORD, NO PLUG, DEDICATED CIRCUIT REQUIRED)

MODEL VOLTAGE PH HZ AMPS kW BREAKER AWG CONNECTION

CTC7–20E

208 – 240 3 50/60 45.7 – 52.7 16.5 – 21.9 50-60 4 – 3 L1, L2, L3, G

380 – 415 3 50/60 28 – 30.4 18.7 – 21.9 32 6 – 4 L1, L2, L3, N, G

440 – 480 3* 50/60 20.6 – 22.4 15.7 – 18.7 25 8 L1, L2, L3, G

*ELECTRICAL SERVICE CHARGE APPLIES

WEIGHT SHIP DIMENSIONS PAN CAPACITY

NET 680 lbs est 308 kg (L x W x H) 56" x 49" x 65"* FULL–SIZE: 20" x 12" x 2-1/2" Sixteen (16)

PRODUCT MAXIMUM: 168 lb (76 kg)

SHIP 727 lbs* 330 kg* (1422 x 1245 x 1651mm)* GN 1/1: 530 x 325 x 65mm Sixteen (16)

VOLUME MAXIMUM: 105 quarts (133 liters)

* .

.

GN 2/1: 650 x 530 x 65mm Eight (8)

** .

**FULL–SIZE SHEET: 18" x 26" x 1" Eight (8)

DIMENSIONS: H x W x D

EXTERIOR:

37-13/16" x 43-3/4" x 46-3/16" (961mm x 1111mm x 1173mm)

EXTERIOR WITH RECESSED DOOR:

37-13/16" x 48-3/4" x 46-3/16" (961mm x 1238mm x 1173mm)

INTERIOR:

23-1/4" x 24-1/4" x 32-3/4" (590mm x 616mm x 832mm)

CTC7-20E

-

WATER REQUIREMENTS WATER QUALITY STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY*

ONE (1) TREATED WATER INLET: 3/4" NPT connection. Line pressure 30 psi minimum dynamic and

90 psi maximum static (200 to 600 kPa) at a minimum flow rate of 0.26 gpm (1 L/min).

ONE (1) UNTREATED WATER INLET: 3/4" NPT connection. Line pressure 30 psi minimum dynamic and

90 psi maximum static (200 to 600 kPa) at a minimum flow rate of 2.64 gpm (10 L/min).

* Both inlets can be from same source. Divide using a manifold. Run one side through treatment device before running to oven.

Must meet line pressure and flow rate specifications for both inlets.

WATER DRAIN: 1-1/2" (40mm) connection with a vertical vent to extend above the exhaust vent.

materials must withstand temperatures up to 200°F (93°C).

It is the sole responsibility of the owner/operator/purchaser of this equipment

to verify that the incoming water supply is comprehensively tested and

if required, a means of “water treatment” provided that would meet

compliance requirements with the published water quality standards shown

below. Non-compliance with these minimum standards will potentially

damage this equipment and/or components and void the original equipment

manufacturer’s warranty. Alto-Shaam recommends using OptiPure

®

[www.

optipurewater.com] products to properly treat your water.

Contaminant

Free Chlorine

Hardness

Chloride

pH

Silica

Total Dissolved Solids (tds)

Inlet Water Requirements

Less than 0.1 ppm (mg/L)

30-70 ppm

Less than 30 ppm (mg/L)

7.0 to 8.5

Less than 12 ppm (mg/L)

Treated line: 50-125 ppm

Untreated line: 50-360 ppm

CLEARANCE REQUIREMENTS

LEFT:

0" (0mm) 18" (457mm) recommended service access

RIGHT:

0" (0mm) Non-combustible surfaces 2" (51mm) door swing or combustible surfaces

TOP:

20" (508mm) for air movement

BOTTOM:

5-1/8” (130mm) for legs, air aintake

BACK:

4" (102mm) 4-5/16” (109mm) optional plumbing kit

INSTALLATION REQUIREMENTS

• Oven must be installed level. • Hood installation is required.

• Water supply shut-off valve and back-flow preventer when required by local code.

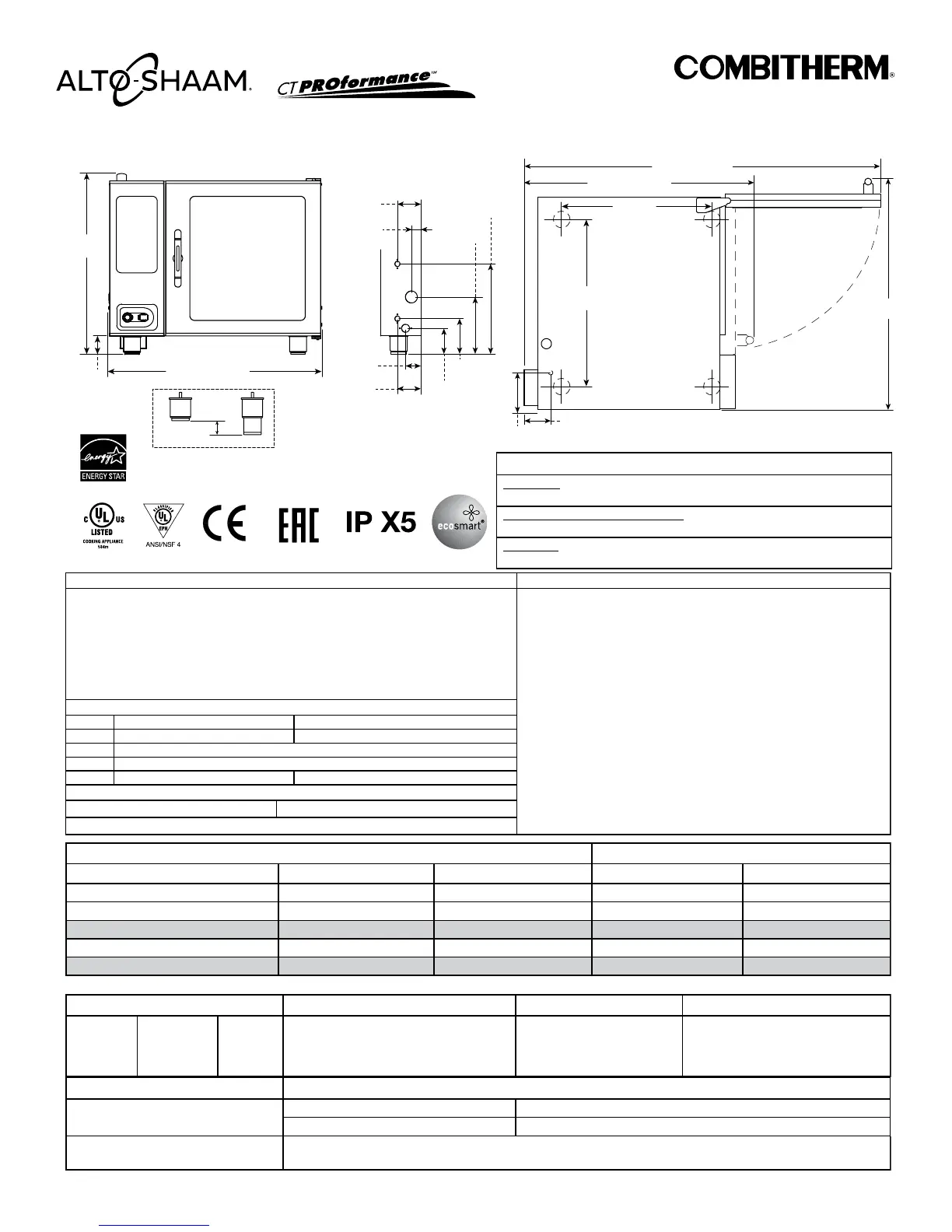

F

C

D

B

A

E: 6-11/16" (168mm)

E: 5-3/8" (136mm)

73 5/16" (1863mm)

46-3/16" (1173mm)

30-13/16"

(783mm)

34-1/4"

(870mm)

47-7/16"

(1205mm)

D: 5-5/8"

(143mm)

C: 7-11/16"

(194mm)

B: 12-3/16"

(309mm)

A: 19-1/16"

(484mm)

B: 2-1/8"

(53mm)

A: 5"

(127mm)

C: 5"

(127mm)

D: 3-5/16"

(84mm)

6" (152mm)

4" (102mm)

43-3/4" (1111mm)

4"

(102mm)

37-13/16"

(961mm)

A = Treated water

B = Electrical (Back)

C = Untreated water

D = Water Drain

E = Electrical (Bottom)

Front

Back

Top/Bottom

#427 - 01/18 DUE TO ONGOING PRODUCT IMPROVEMENT, SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. WWW.ALTO-SHAAM.COM

ELECTRICAL - CTP7-20E

(NO CORD, NO PLUG, DEDICATED CIRCUIT REQUIRED)

WITH COMBISMOKER

®

OPTION

ECO **PROpower™ ECO **PROpower™

VOLTAGE PH HZ AWG CONNECTION AMPS kW BREAKER AMPS kW BREAKER AMPS kW BREAKER AMPS kW BREAKER

208 – 240 1* 50/60 1 – 1/0 L1, L2/N, G 79.1 – 91.3 16.5 – 21.9 80 – 100 92.1 – 106.3 19.2 – 25.5 100 – 110 81.6 – 94.1 17 – 22.6 90 – 100 94.6 – 109.1 19.7 – 26.2 100 – 110

208 – 240 3 50/60 4 – 3 L1, L2, L3, G 45.7 – 52.7 16.5 – 21.9 50 – 60 58.7 – 67.7 19.2 – 25.5 60 – 70 48.2 – 55.6 17 – 22.6 50 – 60 61.2 – 70.6 19.7 – 26.2 70

380 – 415 3 50/60 6 – 4 L1, L2, L3, N, G 28 – 30.4 18.7 – 21.9 32 41.7 – 45.4 21.4 – 25.5 63 30.6 – 33.3 19.3 – 22.6 32 – 63 44.4 – 48.3 22 – 26.2 63

440 – 480 3* 50/60 8 L1, L2, L3, G 20.6 – 22.4 15.7 – 18.7 25 26.5 – 28.8 18.3 – 21.8 30 – 35 21.9 – 23.8 16.2 – 19.2 30 27.3 – 30.0 18.8 – 22.3 30 – 35

*ELECTRICAL SERVICE CHARGE APPLIES

**NO-COST OPTION ON ELECTRIC MODELS

WEIGHT PAN CAPACITY STANDARD MODEL WITH COMBISMOKER

®

OPTION

NET 680 lbs 308 kg

FULL–SIZE: 20" x 12" x 2-1/2" Sixteen (16) Fifteen (15)

GN 1/1: 530 x 325 x 65mm Sixteen (16) Fifteen (15)

SHIP 727 lbs* 330 kg*

GN 2/1: 650 x 530 x 65mm Eight (8) Seven (7)

**FULL-SIZE SHEET: 18" x 26" x 1" Eight (8) Eight (8)

SHIP DIMENSIONS PRODUCT CAPACITY

(L x W x H)

56" x 49" x 65"*

PRODUCT MAXIMUM 168 lb (76 kg)

(1422mm x 1245mm x 1651mm)*

VOLUME MAXIMUM 105 quarts (133 liters)

* .

.

**ON WIRE SHELVES ONLY. ADDITIONAL WIRE SHELVES REQUIRED FOR MAXIMUM CAPACITY

WATER REQUIREMENTS WATER QUALITY STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY*

ONE (1) TREATED WATER INLET: 3/4" NPT connection. Line pressure 30 psi minimum dynamic and

90 psi maximum static (200 to 600 kPa) at a minimum flow rate of 0.26 gpm (1 L/min).

ONE (1) UNTREATED WATER INLET: 3/4" NPT connection. Line pressure 30 psi minimum dynamic and

90 psi maximum static (200 to 600 kPa) at a minimum flow rate of 2.64 gpm (10 L/min).

* Both inlets can be from same source. Divide using a manifold. Run one side through treatment device before running to oven.

Must meet line pressure and flow rate specifications for both inlets.

WATER DRAIN: 1-1/2" (40mm) connection with a vertical vent to extend above the exhaust vent.

materials must withstand temperatures up to 200°F (93°C).

It is the sole responsibility of the owner/operator/purchaser of this equipment

to verify that the incoming water supply is comprehensively tested and

if required, a means of “water treatment” provided that would meet

compliance requirements with the published water quality standards shown

below. Non-compliance with these minimum standards will potentially

damage this equipment and/or components and void the original equipment

manufacturer’s warranty. Alto-Shaam recommends using OptiPure

®

[www.

optipurewater.com] products to properly treat your water.

Contaminant

Free Chlorine

Hardness

Chloride

pH

Silica

Total Dissolved Solids (tds)

Inlet Water Requirements

Less than 0.1 ppm (mg/L)

30-70 ppm

Less than 30 ppm (mg/L)

7.0 to 8.5

Less than 12 ppm (mg/L)

Treated line: 50-125 ppm

Untreated line: 50-360 ppm

CLEARANCE REQUIREMENTS

LEFT:

0" (0mm) 18" (457mm) recommended service access

RIGHT:

0" (0mm) Non-combustible surfaces 2" (51mm) door swing or combustible surfaces

TOP:

20" (508mm) for air movement

BOTTOM:

5-1/8” (130mm) for legs, air aintake

BACK:

4" (102mm) 4-5/16” (109mm) optional plumbing kit

INSTALLATION REQUIREMENTS

• Oven must be installed level. • Hood installation is required.

• Water supply shut-off valve and back-flow preventer when required by local code.

DIMENSIONS: H x W x D

EXTERIOR:

37-13/16" x 43-3/4" x 46-3/16" (961mm x 1111mm x 1173mm)

EXTERIOR WITH RECESSED DOOR:

37-13/16" x 48-3/4" x 46-3/16" (961mm x 1238mm x 1173mm)

INTERIOR:

23-1/4" x 24-1/4" x 32-3/4" (590mm x 616mm x 832mm)

CTP7-20E

-

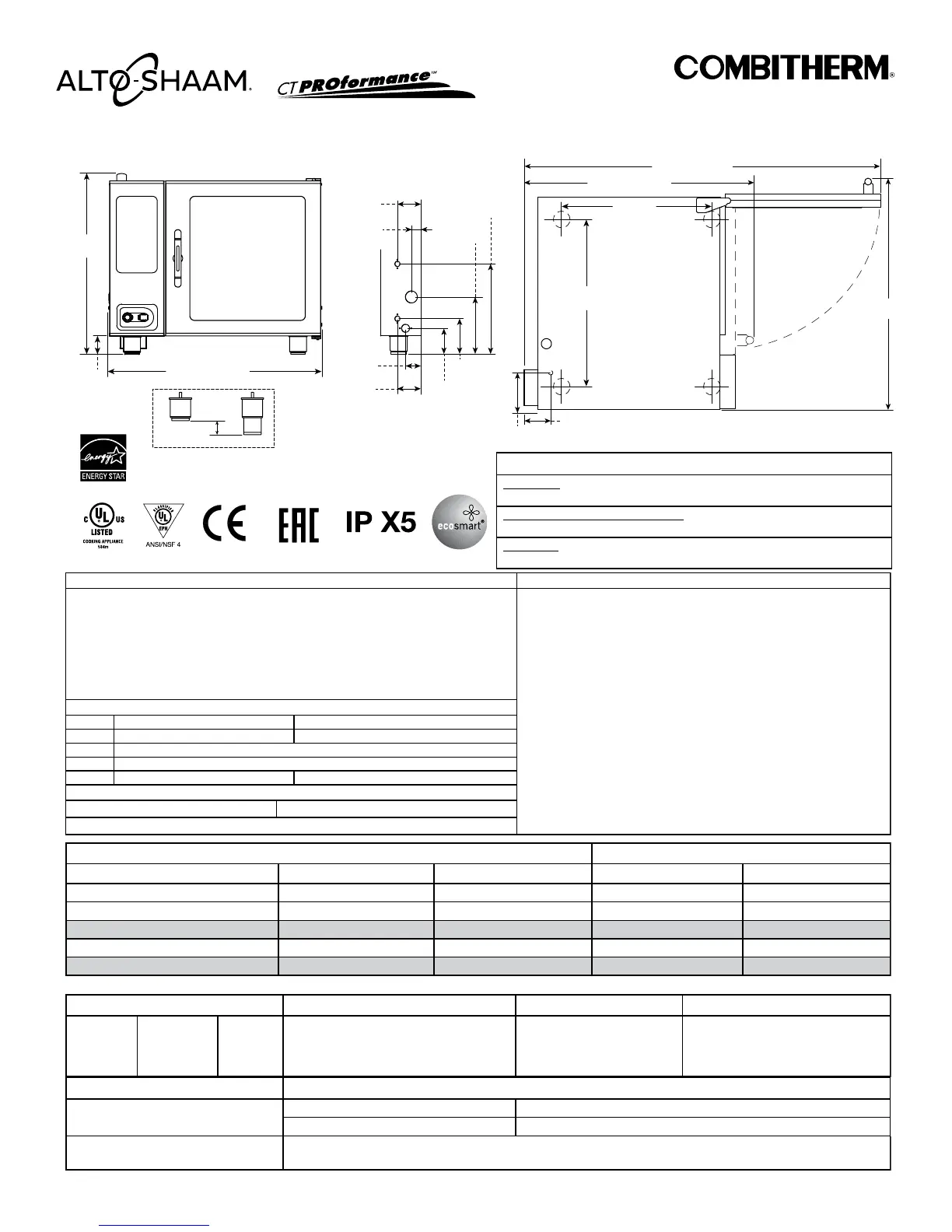

F

C

D

B

A

E: 6-11/16" (168mm)

E: 5-3/8" (136mm)

73 5/16" (1863mm)

46-3/16" (1173mm)

30-13/16"

(783mm)

34-1/4"

(870mm)

47-7/16"

(1205mm)

D: 5-5/8"

(143mm)

C: 7-11/16"

(194mm)

B: 12-3/16"

(309mm)

A: 19-1/16"

(484mm)

B: 2-1/8"

(53mm)

A: 5"

(127mm)

C: 5"

(127mm)

D: 3-5/16"

(84mm)

6" (152mm)

4" (102mm)

43-3/4" (1111mm)

4"

(102mm)

37-13/16"

(961mm)

A = Treated water

B = Electrical (Back)

C = Untreated water

D = Water Drain

E = Electrical (Bottom)

Front

Back

Top/Bottom

Loading...

Loading...