MN-35947

•

Rev 15

•

01/18

•

Combitherm® CT PROformance™ and CT Classic Series Installation Manual

•

77

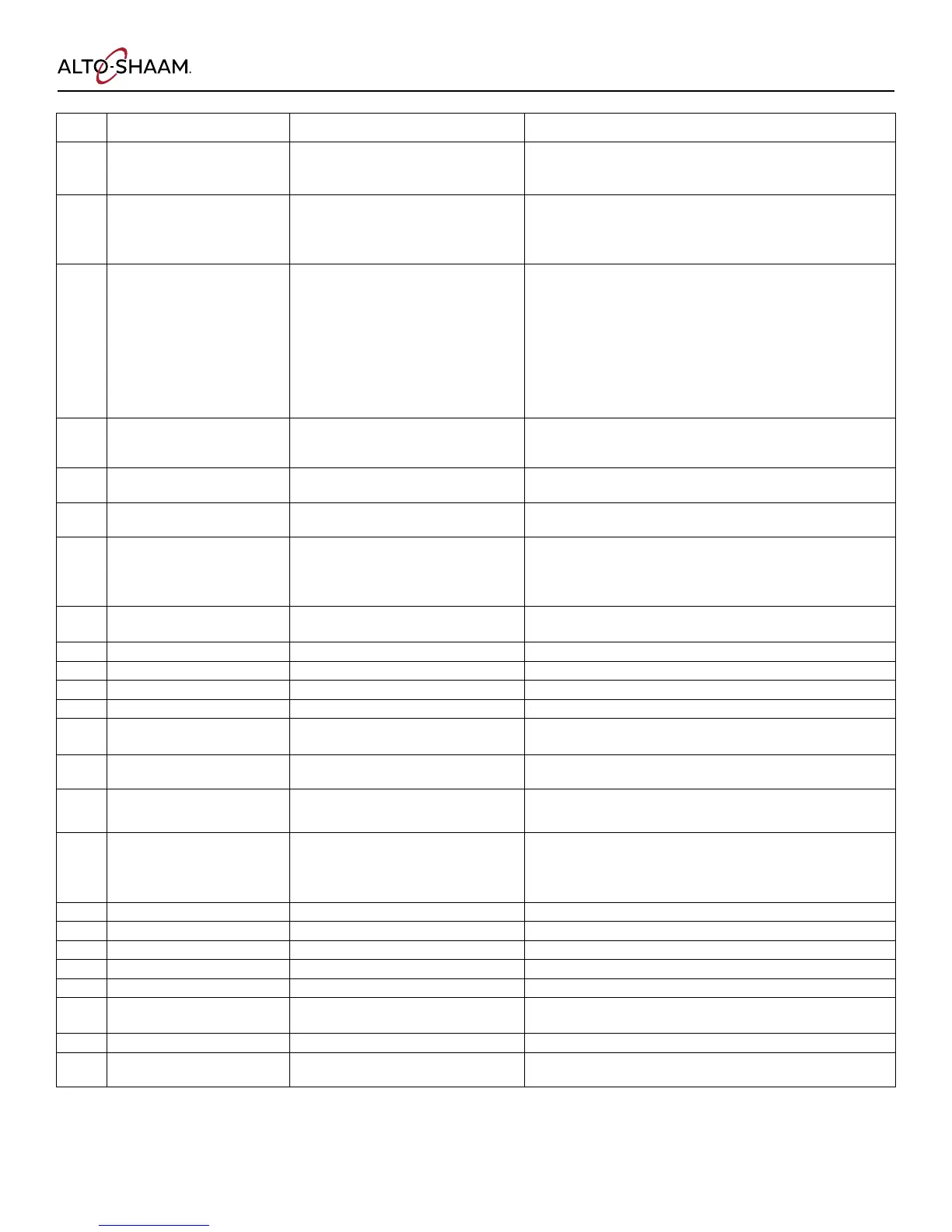

Troubleshooting – Error Codes

Error

Code

Error Call Out in Display Description of Error Possible Cause(s)

E88 Lower Gas Ignition Failure

NOTE: If a er 2 attempts

to clear this error, the error

appears a third time, remove

the oven from service and

immediately contact an

Alto-Shaam authorized service

provider.

Reset output from Ignition Module is ON – Hot surface ignitor not functioning.

– No gas supply.

– Flame sensor not functioning.

– Faulty ignition control.

E89 Upper Gas Ignition Failure

NOTE: If a er 2 attempts

to clear this error, the error

appears a third time, remove

the oven from service and

immediately contact an

Alto-Shaam authorized service

provider.

Reset output from Ignition Module is ON – Hot surface ignitor not functioning.

– No gas supply.

– Flame sensor not functioning.

– Faulty ignition control.

E90 Lower Gas Combustion Blower

Not at Speed

Speed is too slow. – Power supply cable is not connected to blower motor.

– Speed control cable is not connected to blower motor.

– Blower motor is blocked, rotation is impeded, or motor is

faulty.

– Faulty control board.

E91 Upper Gas Blower Not at

Speed

Speed is to slow. – Power supply cable is not connected to blower motor

– Speed control cable is not connected to blower motor

– Blower motor is blocked, rotation is impeded, or motor is

faulty

– Faulty control board

E92 Communication Error

CB does not properly respond

Twelve (12) instances of no-response

from the relay board (CB) to the display

board (IB).

– Check CAN cable connections.

– CAN cable defective.

– Relay board, low voltage, connector defective.

– Display board connector defective.

E93 Interface Board (IB) and

Control Board (CB) are in

di erent states

The IB is in a di erent running state

than the CB for more than 20 seconds.

– Check CAN cable connections.

– CAN cable defective.

– Relay board, low voltage, connector defective.

– Display board connector defective.

E94 Communication Error,

TO Interface Board

No signal transfer for more than 20

seconds between the Interface Board

(IB) and the Control Board (CB).

– Check CAN cable connections.

– CAN cable defective.

– Relay board, low voltage, connector defective.

– Display board connector defective.

E100 One or more maintenance

reminder has timed out.

When any maintenance reminder has

expired without action having been

taken by the operator.

–

Enter maintenance reminder screen and address the item

that has timed out and reset

E101 Ventless Hood Fault - No

Pressure

If the power switch or pressure switch is

not closed.

– Check power switch is on.

– Check vent motor is turning in the proper direction.

– Pressure switch is miss wired or defective.

– Filter(s) require cleaning or replacement

E102 Ventless Hood Fault – Filters

Not Present

If the air filter switches are not closed.

– Check filters are installed and properly seated.

– Check filter switches are not damaged, defective or

dislodged.

E103 Option Board Doesn’t Send

Switch Setting

OB not communicating its switch

settings to the CB.

– Check CAN cable connection between OB and CB.

– Ensure CB dip switch is set to see an OB.

– Incompatible OB and CB so ware (update so ware).

– OB defective.

– CB defective.

E104 Option Board Not

Communicating

Option board is not communicating

with CB.

– Check option board CAN connection at CB and OB.

– Defective OB.

– Defective CB.

E105 No or Low Water Pressure Water pressure switch not activated.

– Water supply not connected.

– Water supply is shut o .

– Water supply to unit blocked or obstructed

– Faulty or miswired pressure switch

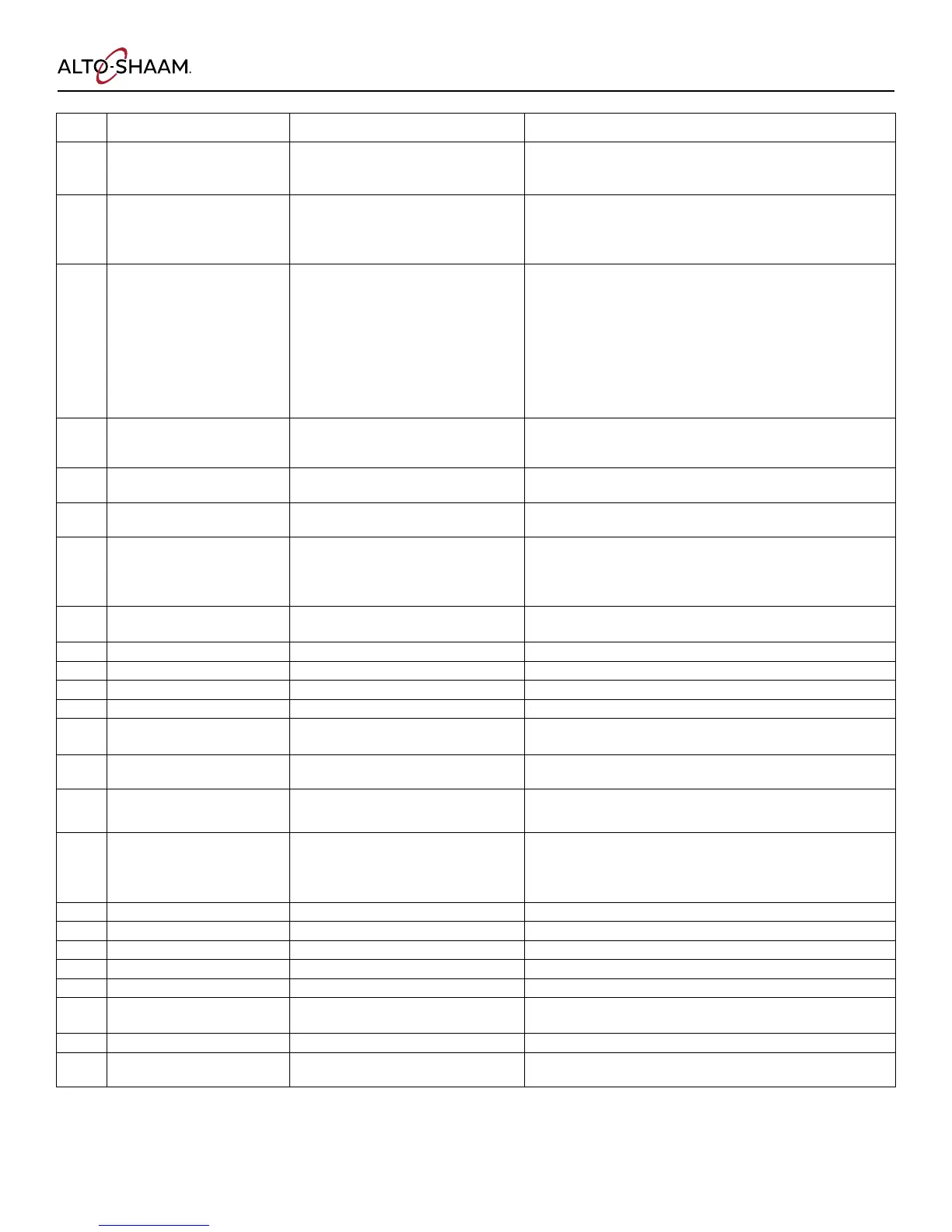

Error

Code

Error Call Out in Display Description of Error Possible Cause(s)

E106 Boiler Drain Pump Fault Hall e ect or rotational sensor is not

sending a signal to the relay board

– Drain pump motor not running or defective.

– Hall e ect sensor broken or incorrectly wired.

– Motor improperly wired.

E108 Cooling Fan Failure If the temperature on the control board

(relay board) is greater than 140ºF

(60ºC) and less than 176ºF (80ºC). (See

error code E02)

– Cooling fan damaged.

– Cooling fan blocked or blades have been kept from rotating.

– Incoming air temperature exceeds 100°F (38°C).

– Air inlet has become blocked.

E109 High Limit Switch

NOTE: Any oven experiencing

this error should be

investigated by an authorized

Alto-Shaam service provider.

The High Limit Switch input to the CB

(N7) is “open”

– Unit has experienced an over heat condition.

– Convection element contactors stuck closed.

– Failed Y1 solenoid.

– Obstruction between Y1 solenoid and injection pipe.

– Improperly connected drain.

– Condensate pan clean out not closed.

– Improperly wired high limit switch at the switch or at the

CB.

– Defective high limit switch.

E200 The SD card has been

detected to be larger than

2GB in size.

The SD card inserted is larger than 2GB

in size.

– SD card is larger than 2GB in size. Contact service to order

replacement SD card.

E210 VFD Under Voltage VFD has detected an under-voltage

situation.

– Possible VFD failure.

E211 VFD Over Voltage VFD has detected an over-voltage

situation.

– Possible VFD failure.

E212 VFD Overheating VFD has detected an overheat

situation.

– Unit has experienced an over heat condition.

– Defective high limit switch.

– Defective cooling fans.

– Possible VFD failure.

E213 Motor Over Current Motor over current detected.

– Blocked fan wheel.

– Possible VFD failure.

E214 VFD Current Peak VFD current peak detected.

– Possible VFD failure.

E215 VFD EEPROM Error VFD EEPROM error detected.

– Possible VFD failure.

E216 VFD Over Current VFD over current detected.

– Possible VFD failure.

E217 VFD Short Circuit VFD Short Circuit detected.

– Possible VFD failure.

E218 VFD Voltage Error VFD voltage does not correspond to

jumper settings.

– VFD voltage jumper is not correct.

– Possible VFD failure.

E220 Lower VFD Under Voltage Lower VFD has detected an under-

voltage situation.

– Possible Lower VFD failure.

E221 Lower VFD Over Voltage Lower VFD has detected an over-

voltage situation.

– Possible Lower VFD failure.

E222 Lower VFD Overheating Lower VFD has detected an overheat

situation.

– Unit has experienced an over heat condition.

– Defective high limit switch.

– Defective cooling fans.

– Possible Lower VFD failure.

E223 Lower Motor Over Current Lower Motor over current detected.

– Possible Lower VFD failure.

E224 Lower VFD Current Peak Lower VFD current peak detected.

– Possible Lower VFD failure.

E225 Lower VFD EEPROM Error Lower VFD EEPROM Error detected.

– Possible Lower VFD failure.

E226 Lower VFD Over Current Lower VFD over current detected.

– Possible Lower VFD failure.

E227 Lower VFD Short Circuit Lower VFD short circuit detected.

– Possible Lower VFD failure.

E228 Lower VFD Voltage Error Lower VFD voltage does not

correspond to jumper settings.

– Lower VFD voltage jumper is not correct.

– Possible Lower VFD failure.

E289 Unknown Error from VFD VFD has provided an unknown error.

– Possible VFD failure.

E290 Unknown Error from Lower

VFD

Lower VFD has provided an unknown

error.

– Possible Lower VFD failure.

Loading...

Loading...