5000KIT | 5000KIT AUTOMATION SET 69

MOUNTING

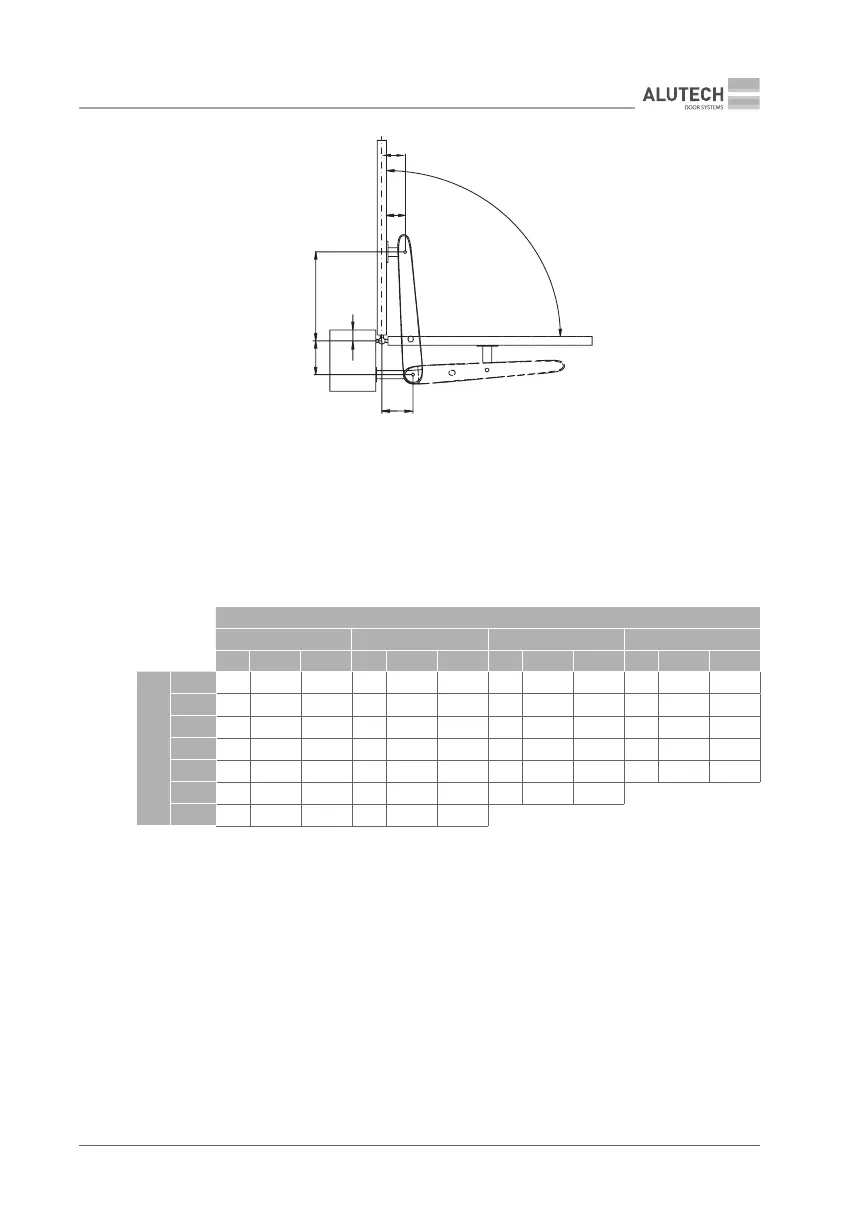

A

W

C

B

α

E

Figure 5. Mounting diagram for a gate opening outwards

and — dimension between the leaf hinge axis (leaf rotation centre)

and the axis for mounting a drive on its rear tting; C — dimension between the leaf hinge axis and a post edge;

W — dimension between the leaf hinge axis and the axis for mounting a drive on its front tting;

E — dimension between a leaf edge and the axis for mounting a drive on its front tting (g.8),

minimumdimension Е = 134mm; α — leaf opening angle;

X — dimension between the leaf hinge axis (leaf rotation centre) and

the axis for mounting a drive on its front tting.

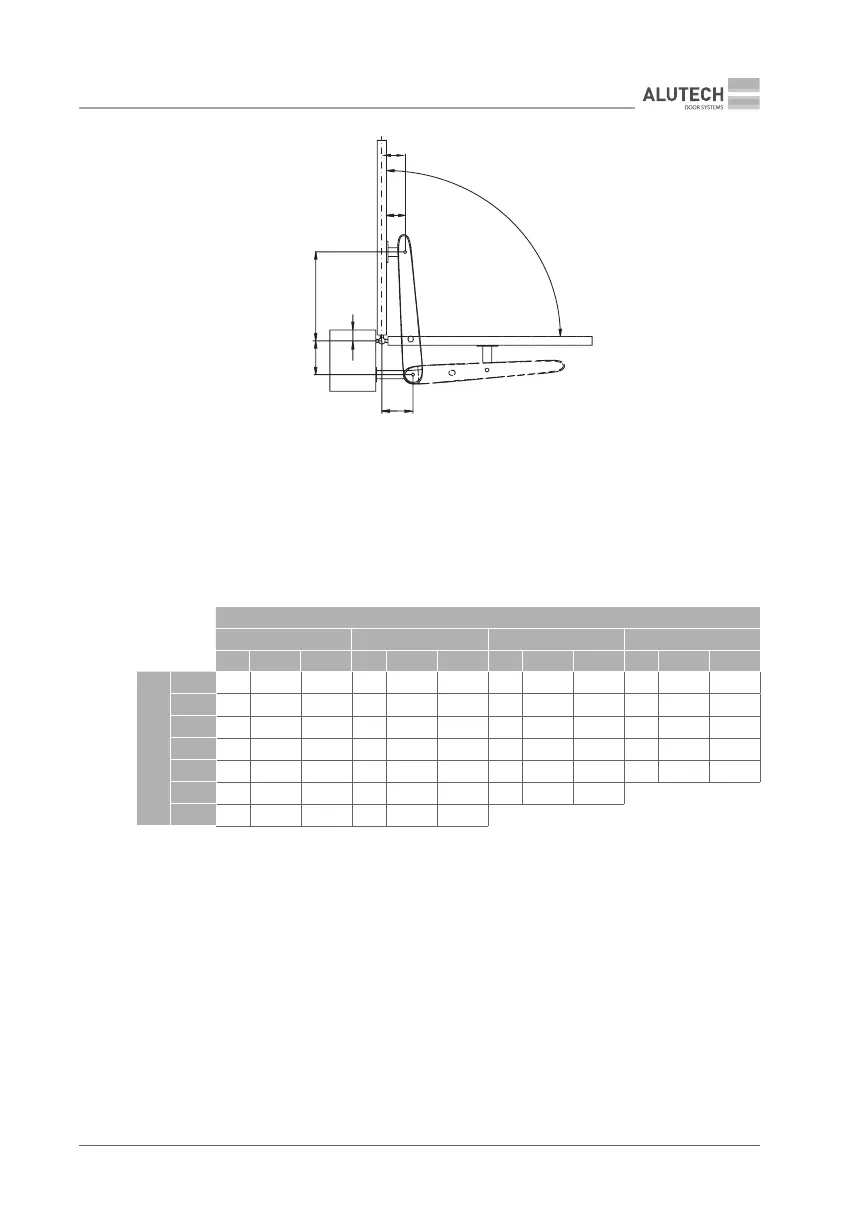

A MM

170 190 210 230

α° C (mm) W (mm) α° C (mm) W (mm) α° C (mm) W (mm) α° C (mm) W (mm)

B MM

170

90 − 40 750 95 − 40 735 100 − 40 715 100 − 40 725

170

90 − 20 750 95 − 20 735 100 − 20 715 100 − 20 725

170

90 0 750 95 0 735 100 0 715 100 0 725

190

90 20 750 95 20 735 100 20 735 95 20 725

210

90 40 750 95 40 735 95 40 745 90 40 725

230

90 60 750 95 60 760 90 60 740

250

90 80 760 90 80 760

Pay attention to the following:

• the A and B dimensions must be almost equal, while the travel length S should be maximum

to ensure constant speed and pushing (pulling) force when a leaf is moving, i.e., a smoother

motion of the leaf.

• the sum of the A and B values should be almost equal to the useful drive travel required

toopen a leaf to the angle α = 90 º.

• pay special attention to the C dimension to avoid the drive hitting a post edge.

• The condition B > X should be observed. Avoid the drive hitting a gate post.

• when a gate is closed or open, the drive should be at an angle to a leaf (fig. 6).

• note that, for a gate opening outwards, the drive-through width may be reduced due to the

drives overhanging into the drive-through area (fig. 7).

Table 5

Loading...

Loading...