34

9.6 ACCESSORIES KIT FOR LINKAGE SENSOR TOP LINK MX

Through this sensor, the seeding shaft of the implement can start and

stop rotating automatically when lifting and lowering the implement.

Order number: 00410-2-169

Connection: 12-pin plug on the control box

Settings: see chapters 8.8 and 8.9

Cable length: 3 m

Installation position: Since most soil tillage implements are lifted

and lowered during their operation, installing

this sensor on the implement's three-point

linkage is the best method. However, the

sensor can also be attached at other

positions that have mechanical movement.

The programming (position in which work is

performed) can be adapted for this purpose.

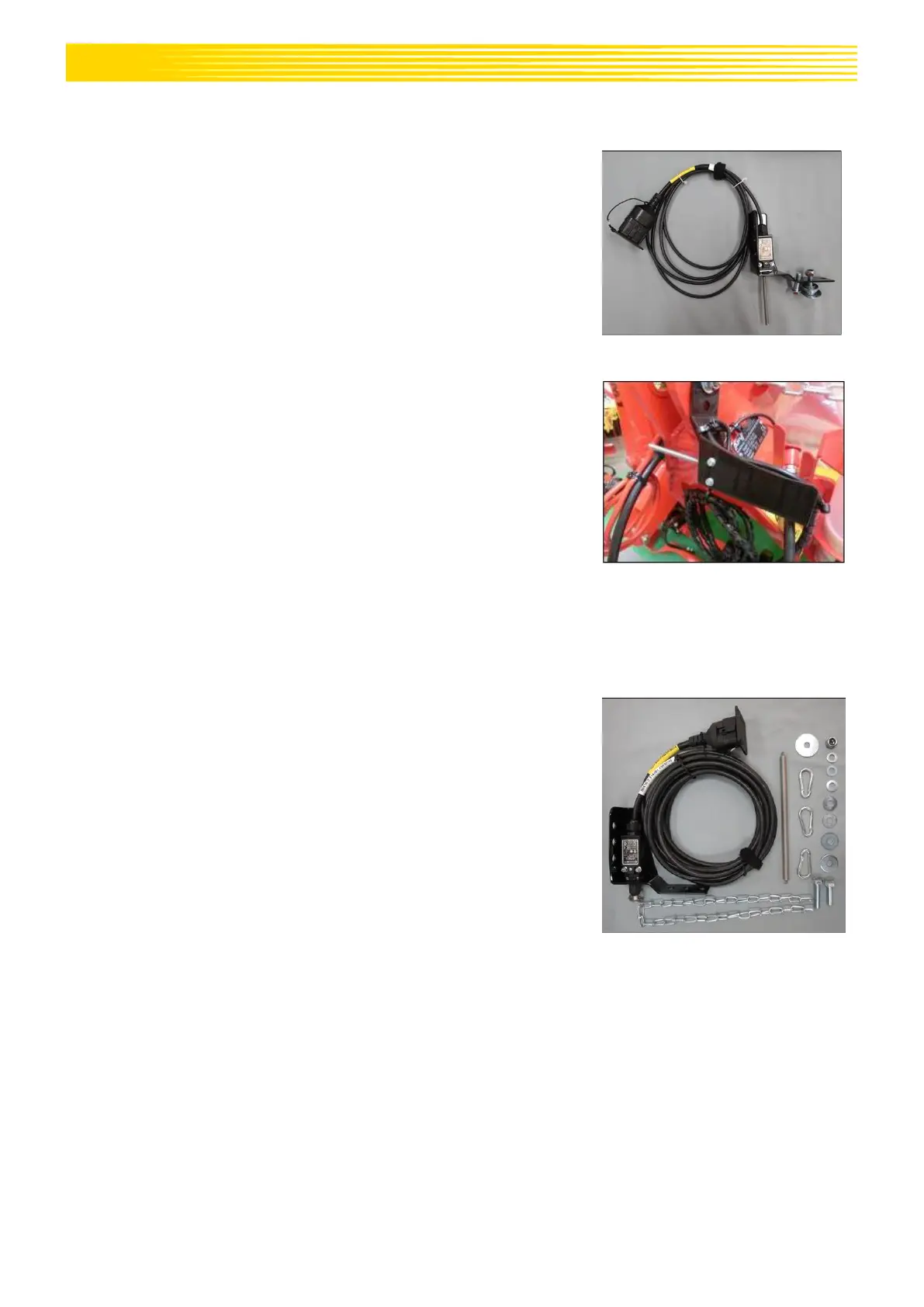

9.7 ACCESSORIES KIT FOR LINKAGE SENSOR PULL SWITCH MX

Through this sensor, the seeding shaft of the implement can start and

stop rotating automatically when lifting and lowering the implement.

Order number: 00410-2-174

Connection: 12-pin plug on the control box

Settings: see chapters 8.8 and 8.9

Cable length: 5 m

Scope of delivery: 1 sensor, 1 fastening plate incl. fastening

bolts

Installation position: Via a spring (for length compensation) and a chain, two points – which move

relative to each other when lifting the implement – can be connected. The switch

is activated by the change in length and switches off the seeding shaft. The pull

switch can be installed on the three-point and can be tensioned with the chain, e.g.

on the towing hitch on the tractor. Now if the implement is lifted out, the distance

between the two points increases and the pull switch switches off the seeding shaft.

However, the switch can also be installed parallel to cylinders in the

parallelograms, where a relative movement between the two points takes place

during the lift-out procedure. In the programming you can specify whether seeding

should occur with the switch activated or not activated.

Loading...

Loading...