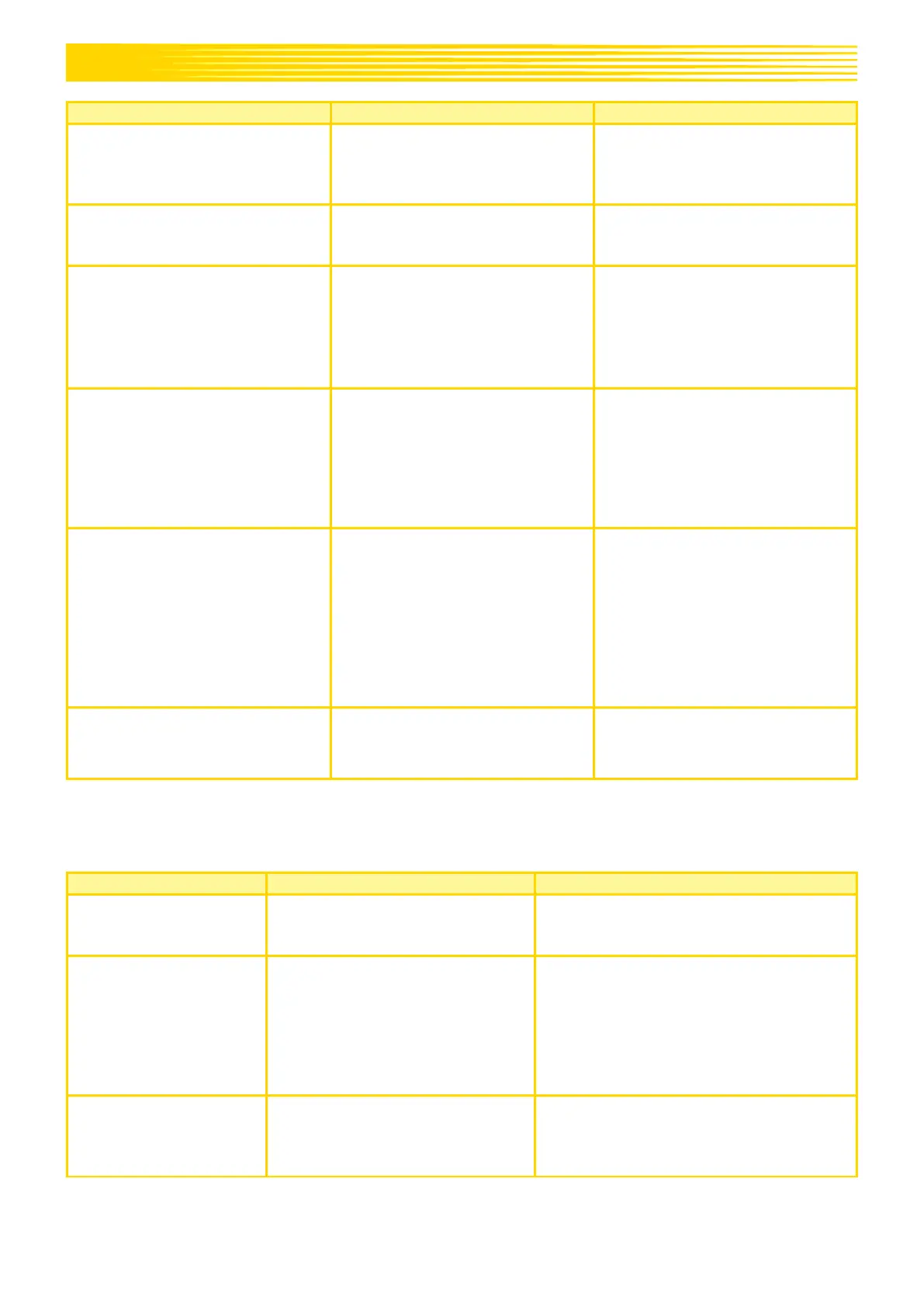

25

The motor is connected and not

overloaded, but still does not

rotate.

Check the clamp

connections on the

spreader.

Contact customer service.

◯

X No motor speed

(spreading plate)!

The motor is connected and not

overloaded, but still does not

rotate.

Contact customer service.

◯

X No motor speed (pump)!

The flow sensor connection

(blue) is not or not properly

connected.

The pump is running at its

minimum and cannot reach the

spread rate.

Check the cabling.

Reduce the speed.

Increase the spread rate.

Smaller nozzles.

Fewer outlets.

The control box is not receiving

any signals from the speed

sensor.

Check the ground wheel,

sensor, cables and plugs.

If a defects cannot be found

on the ground wheel that

explain the malfunction,

please contact customer

service.

The speed of the hydraulic

fan is below the lower limit (set

in Point 5.10).

The pulses/revolution

parameter is incorrectly set.

Switch on the hydraulic fan.

Increase the speed of the

hydraulic fan.

Set the pulses/revolution

parameter correctly, see

Point 5.10.

A speed sensor is not

installed on the fan, see

Point 4.4.5.

△

! Short circuit on the

sensor lines!

The sensor supply lines are

overloaded.

A short circuit occurred.

Check the cables for

damage and short circuits.

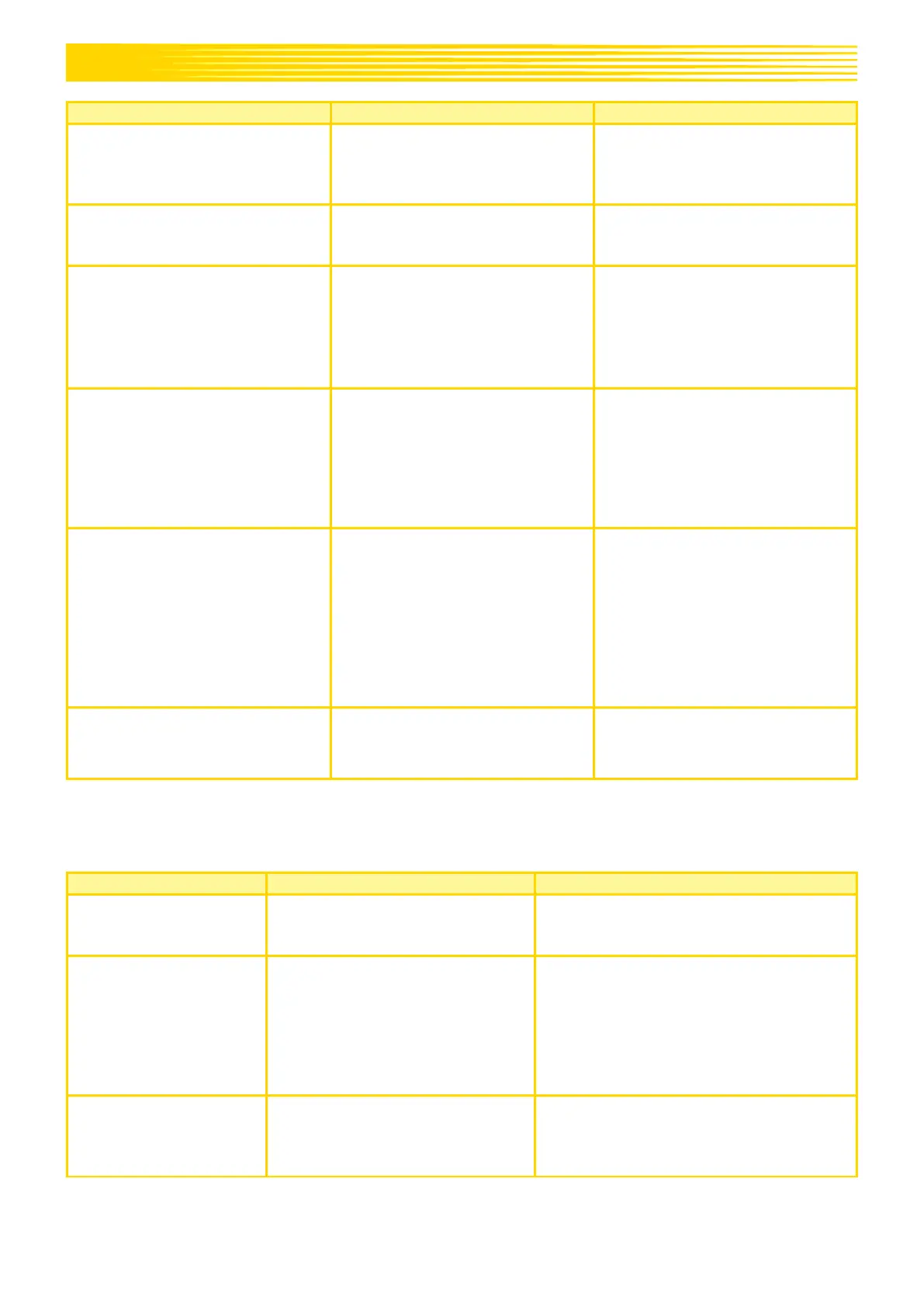

7 PROBLEM SOLVING

Seeding shaft rotates

when the implement is

lifted.

Invert the tractor linkage signal, see

chapter 8.9.

Reposition the linkage sensor.

Seeding shaft does not

rotate when the

implement is in working

position.

Seeding shaft is not switched

on.

Forward speed is zero.

No linkage signal.

Switch on the seeding shaft. The

seeding shaft must be switched on

manually one time at the beginning.

Check the settings for the speed

sensor, see chapters 8.4 – 8.7.

Check the speed sensor.

Check the linkage sensor.

The fill level sensor is

installed, but is not

transmitting.

No signal from the fill level

sensor.

Adjust the sensitivity of the fill level

sensor (screw on the rear side).

Reposition the fill level sensor.

Check the plug and cable.

Loading...

Loading...