Manual, Robotic Tool Changer, QC-5 through QC-27

Document #9610-20-2254-09

Pinnacle Park • 1041 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

24

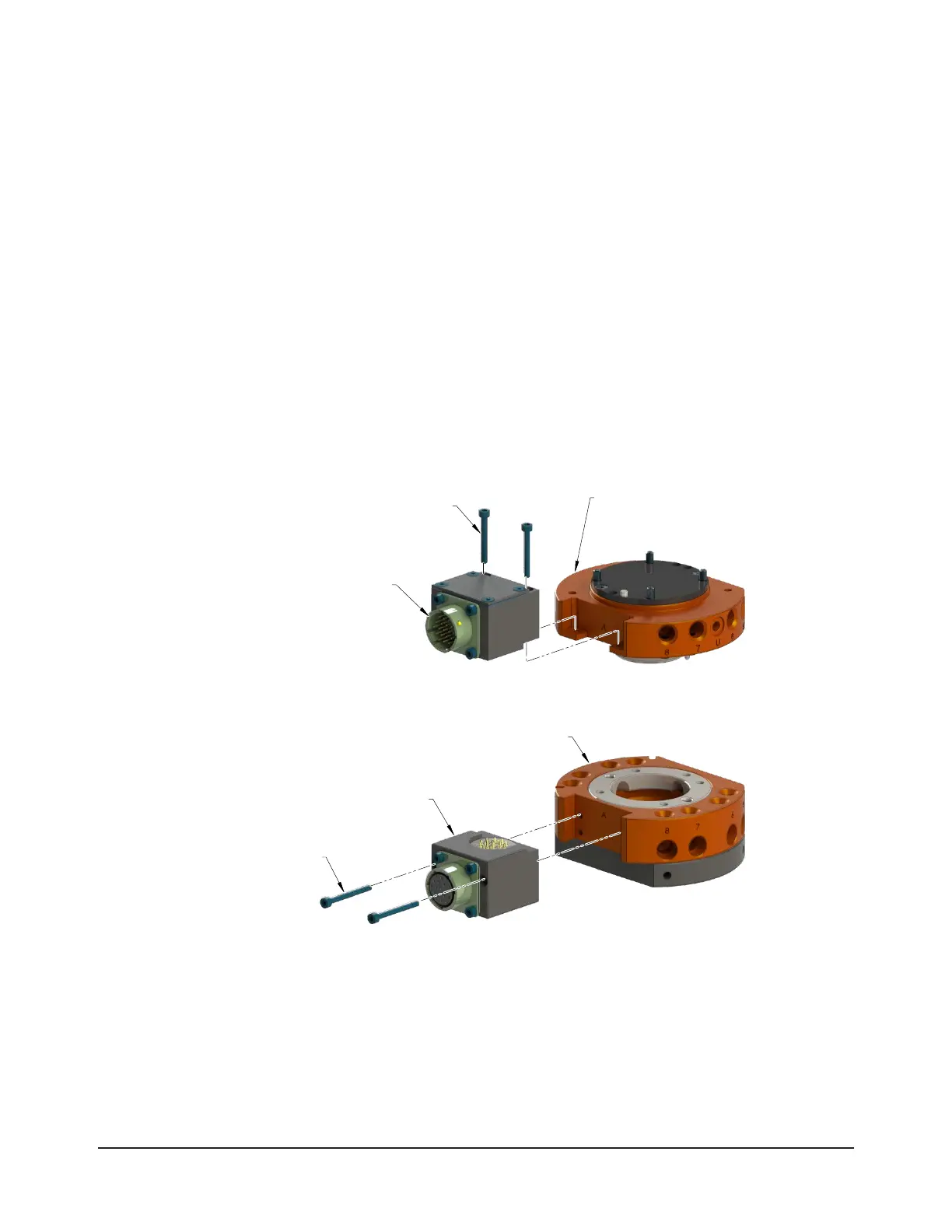

3.7.7 QC-20, QC-21, and QC-27 Flat A Optional K Series Module Installation

Tools required: 2.5 mm hex key, torque wrench

Supplies required: Clean rag, Loctite 222

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

4. Ensure that the mounting surface is clean.

5. Align the optional module on at A of Master or Tool plate assembly.

6. Apply Loctite 222 to the M3 socket head cap screws.

7. Secure the module with (2) M3 socket head cap screws using a 2.5 mm hex key. Tighten to

10 in-lbs (1.13 Nm).

8. Remove all protective caps, plugs, tape, etc from the module prior to operation.

9. Connect the utility cable(s).

10. Safely resume normal operation.

Figure 3.7—QC-20 and QC-21 Flat A Optional K Series Module Installation

Electric Module

(9120-K19-T)

Tool Plate Assembly

(QC-21 Shown)

(QC-21 Shown)

(2) M3 Socket Head

Cap Screw

Electrical Module

(9120-K19-M Shown)

(2) M3 Socket Head

Cap Screw

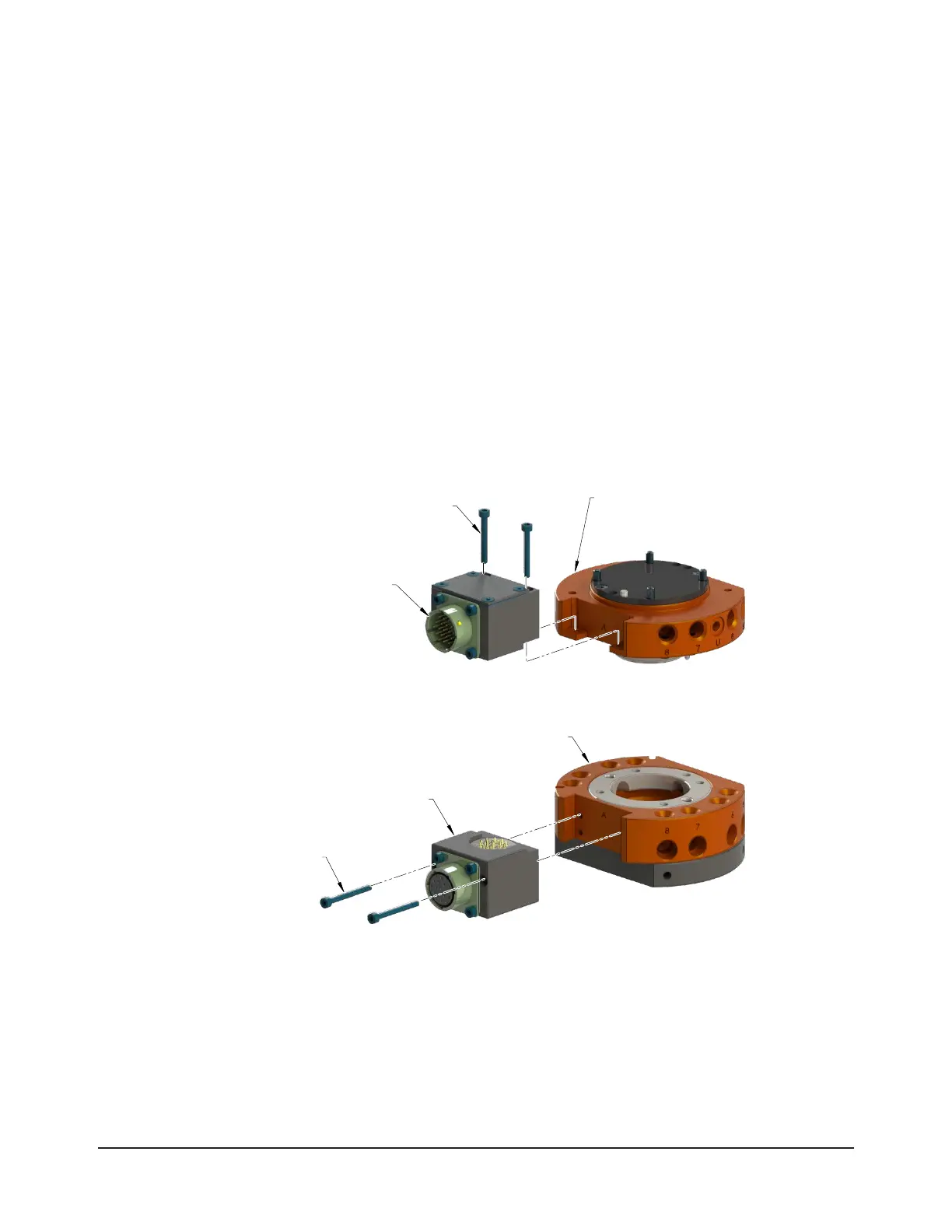

3.7.8 QC-20, QC-21, and QC-27 Flat A Optional K Series Module Removal

Tools required: 2.5 mm hex key

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect the utility cable(s).

Loading...

Loading...