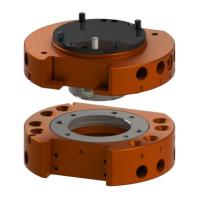

Manual, Robotic Tool Changer, QC-5 through QC-27

Document #9610-20-2254-09

Pinnacle Park • 1041 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

41

5.1 Preventive Maintenance

The Tool Changer and optional modules provide a long life with regular maintenance. A maintenance

schedule for an application and a maintenance checklist is provided in the following table. Detailed

assembly drawings are provided in Section 9—Drawings of this manual.

Table 5.1—Maintenance

Application(s)

Tool

Change Frequency

Inspection

Schedule

General Usage Material Handling Docking Station

> 1 per minute Weekly

< 1 per minute Monthly

Welding/Servo/Deburring, Foundry Operations (Dirty

Environments)

All Weekly

Checklist

Mounting Fasteners

г Inspect fasteners for proper torque, interferences, and wear. Tighten and correct as required. Refer

to Section 3—Installation.

Ball Bearings/Alignment Pins/Bushings/Bearing Race

г Inspect for wear and proper lubrication. MobilGrease XHP222 Special a NLGI #2 lithium complex

grease with molybdenum disulde additive is suggested for locking mechanism and alignment

pin lubrication. Over time, lubricants can become contaminated with debris. Therefore, it is

recommended to thoroughly clean the existing grease and replace with new as needed. See

Section 5.2—Cleaning and Lubrication of the Locking Mechanism and Alignment Pins.

г Inspect for excessive alignment pin/bushing wear that may be an indication of poor robot position

during pickup/drop-off. Adjust robot position as needed. Check tool stand for wear and alignment

problems. The QC-27M model has replaceable alignment pins, refer to Section 6.2.4—QC-27M

Alignment Pin Replacement.

г Wear on the balls/bearing race could be an indication of excessive loading.

Sensors and Cables

г Inspect sensor cable connectors for tightness, and if loose, tighten the connections.

г Inspect sensor cables for any damage, cuts, and abrasion. Replace as necessary. Refer to

Section 6.2.1—QC-11 and QC-27 Proximity Sensor Adjustment, Test, or Replacement or

Section 6.2.2—QC-20 and QC-21 Proximity Sensor Adjustment, Test, or Replacement

Hoses

г Inspect the hose connection for tightness and leaks. If leaking or loose, secure the hose connection.

г Inspect hoses for interferences, abrasions, cuts, and leaks. Replace as required.

Electrical Contacts/Pin Block (Modules)

г Inspect for damage, debris, and stuck/burnt pins. Refer to Section 5.3—Optional Electrical Module

Pin Block Inspection and Cleaning.

Seals Pass Through Air and Optional Modules

г Exposed seals and rubber bushings may damaged during normal operation. Inspect for

wear, abrasion, and cuts. Replace damaged seals or rubber bushings as needed. Refer to

Section 6.2.3—Rubber Bushing Inspection and Replacement, or Section 6.2.5—Optional Electrical

Module V-ring Seal Inspection and Replacement

Loading...

Loading...