Manual, Robotic Tool Changer, QC-5 through QC-27

Document #9610-20-2254-09

Pinnacle Park • 1041 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

63

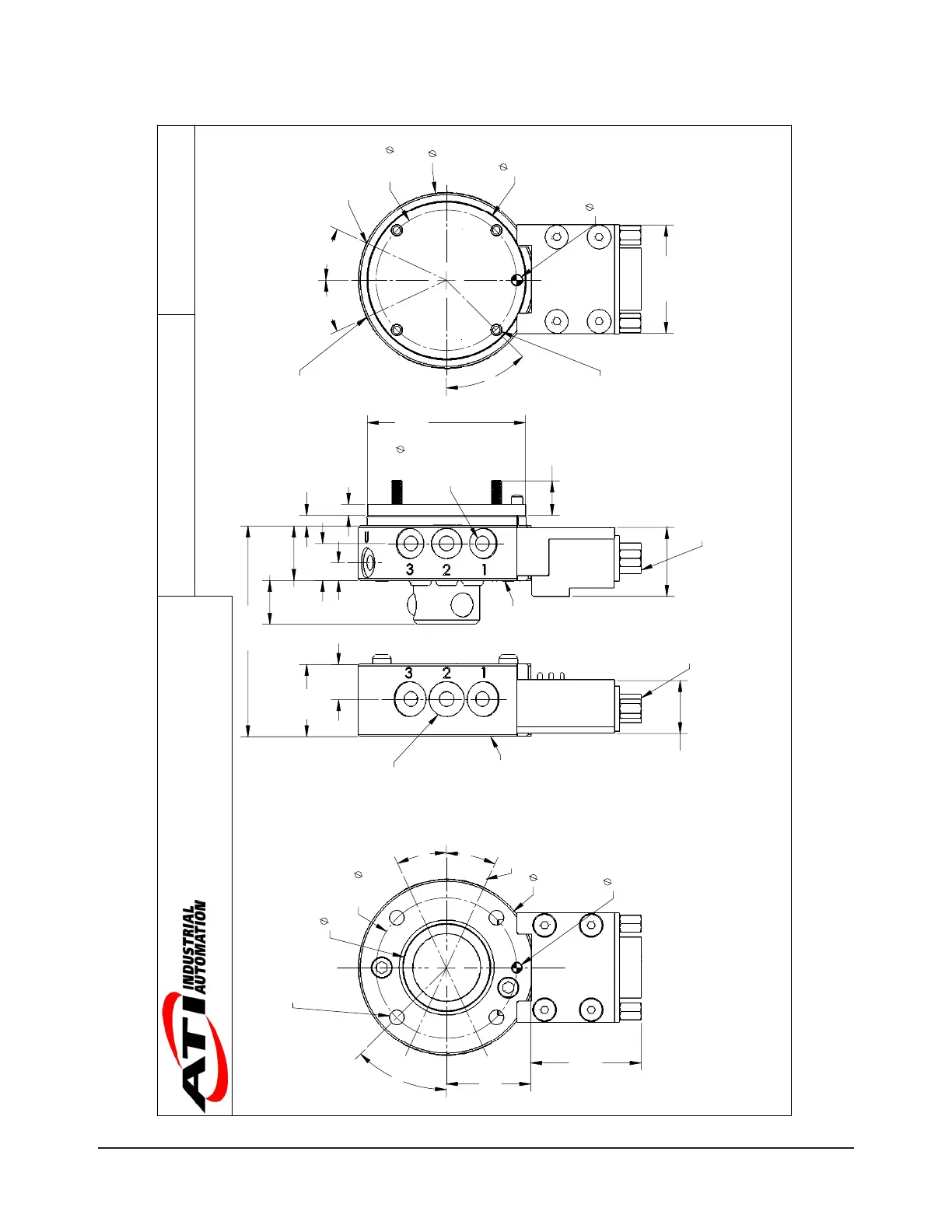

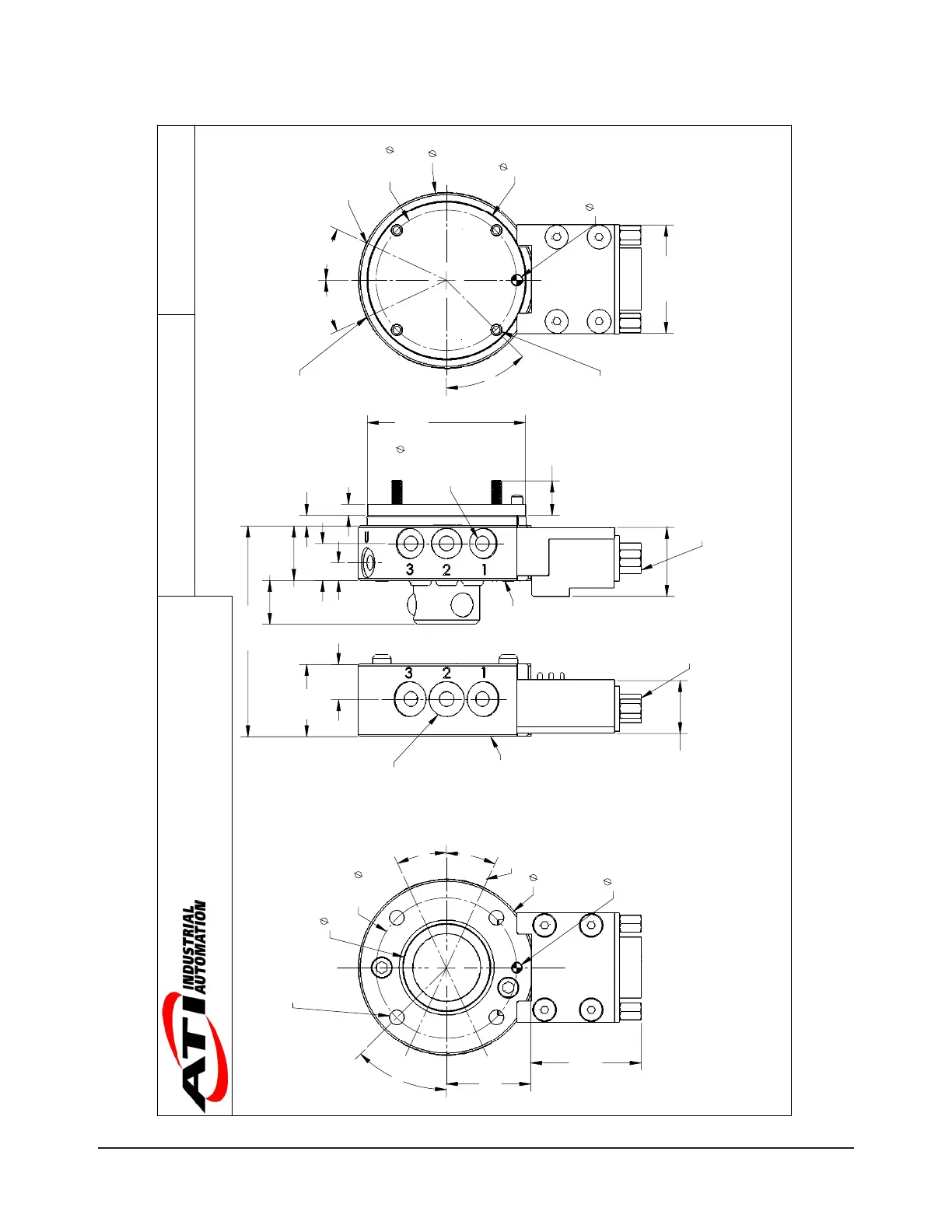

9.2 QC-11 Tool Changer with A15 Module

25

H8, 5 Dp.

Customer Interface

3

H7, 5 Dp.

Customer Interface

50

24

(Typ.)

31.5

A15

Modules

B.C.

40

45°

25°

25°

4X Tapped M5 x .8, 8 Dp.

Equally Spaced

Customer Interface

2

3

6

5

4

Tool Side

(projection only)

Pneumatic

Port I.D.

1

20.6

Tool

Plate

12.5

Male

Coupling

3.2

Cover Plate

Coupled

36.1

15.1

A15-T

19.6

A15-M

45

h7, Boss

Customer

Interface

15.5

Master

Plate

9.8 M3 SHCS

Provided

3 Boss

10 5

10.5

6X M5

Pneumatic

Thru Ports

(A)

(B)

HD D-Sub 15

Female Connector

HD D-Sub 15

Male Connector

6X M5

Pneumatic

Thru Ports

44.7

Cover

Plate

3

H7, 5 Dp.

Customer Interface

30.8

A15

Modules

50

B.C.

40

25° 25°

45°

4X Thru Hole for M3 x 25

SHCS Provided

Equally Spaced

Customer Interface

M5 Unlock

Port

M5 Lock

Port

Master Side

(projection only)

Part Numbers Shown:

(A) Master: 9120-011M-A15-000

(B) Tool: 9120-011T-A15-000

Notes:

1. Master mounting hardware provided.

2. Cover plate is not necessary if robot interface plate provides

sealing. The recommended interface plate bore depth without

a cover plate is 2.5mm, with a cover plate is 5.6mm.

3. Orientation marks are provided to assist in robot teaching.

4. Shown with optional A15 Electrical Modules. For other modules

see the Modules and Options section of the catalog.

Warning:

Do not apply lock/unlock air pressure without master cover plate

properly attached. If cover plate is not used, master should be

properly attached to interface. Failure to do so could result in

damage to cover plate and o-ring.

QC-11 Tool Changer

9230-20-1963-05

1031 Goodworth Drive, Apex, NC 27539, USA

Tel: +1.919.772.0115 Email: info@ati-ia.com

Fax: +1.919.772.8259 www.ati-ia.com

ISO 9001 Registered Company

Loading...

Loading...