- 44 -

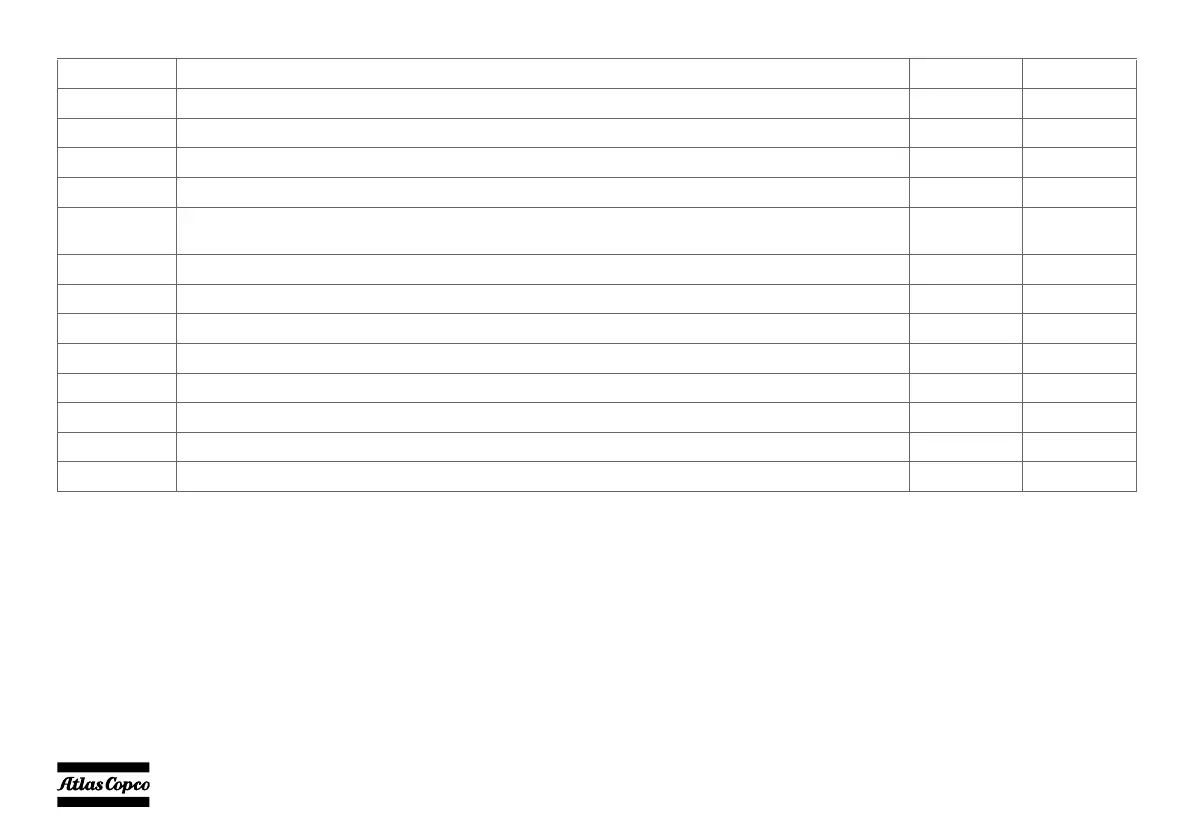

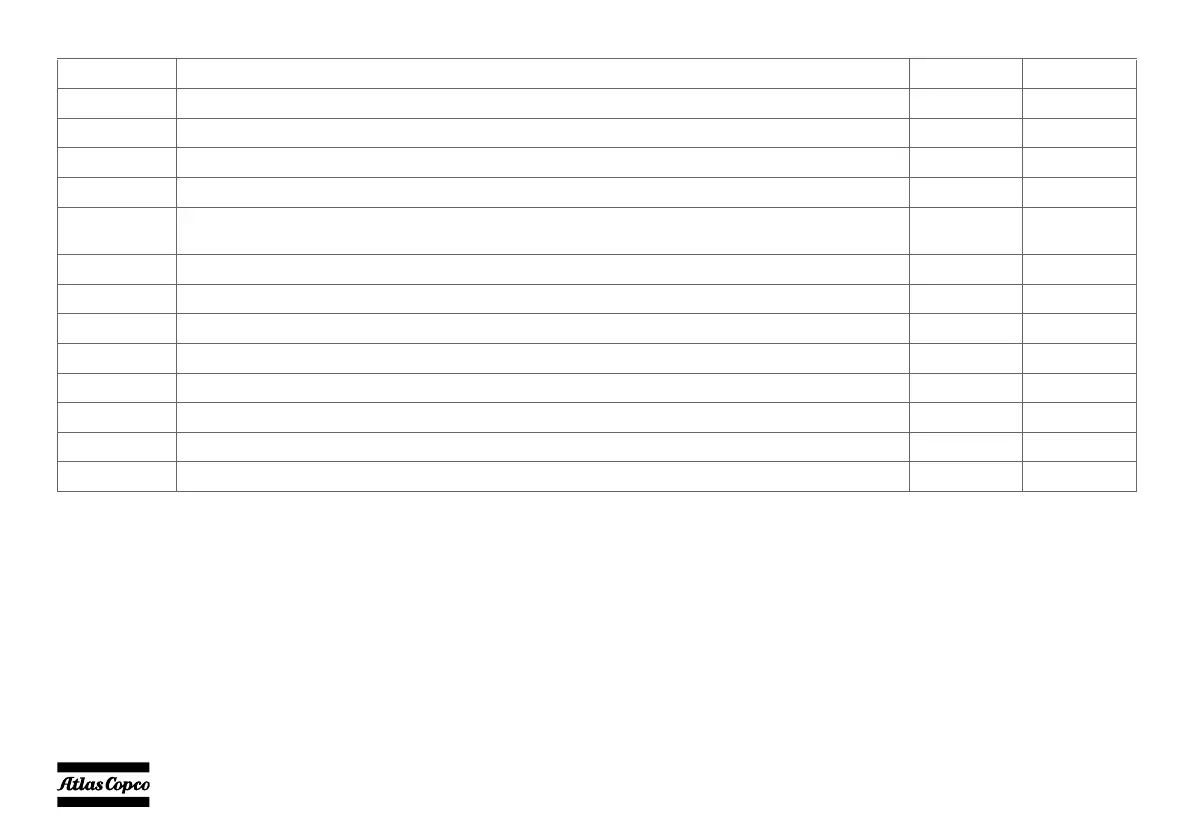

Notes

(1) More frequently when operating in a dusty environment.

(2) See section “Critical bolt connections” on page 72.

(3) The function of this protection should be tested minimum on every new installation.

Category Maintenance schedule (km)

Every 500 km Yearly

Undercarriage

Check tyre pressure 2,5 bars xx

Undercarriage

Check tyres for uneven wear xx

Undercarriage

Check torque of wheel nuts 120 Nm xx

Undercarriage

Check torque of coupling head 82 Nm xx

Undercarriage

Check towbar handbrake lever spring actuator, reversing lever, linkage and all movable parts for ease of movement

83 Nm

xx

Undercarriage

Grease coupling head, towbar bearings at the housing of the overrun brake x

Undercarriage

Check brake system (if installed) and adjust if necessary x

Undercarriage

Oil or grease brake lever and moving parts such as bolts and joints x

Undercarriage

Grease sliding points on height adjusting parts x

Undercarriage

Check safety cable for damage xx

Undercarriage

Check electrical cable towards road signalisation x

Undercarriage

Check brake pads wear x

Undercarriage

Change wheel hub bearing grease x

00_00_ZBP45_EN.book Page 44 Monday, October 19, 2020 9:52 AM

Loading...

Loading...