Installation Page 5/51

MID_M2000_BA_02_1807

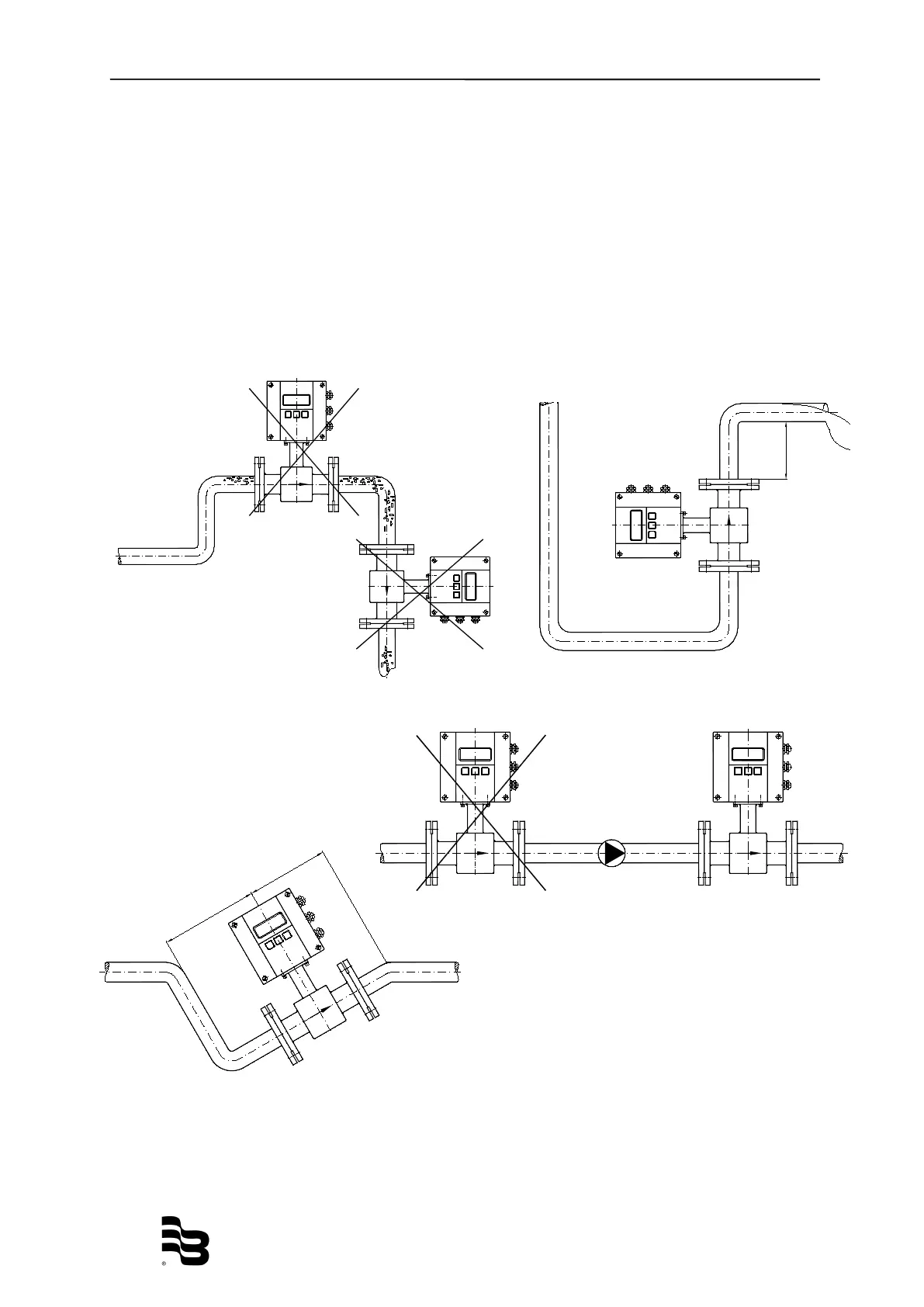

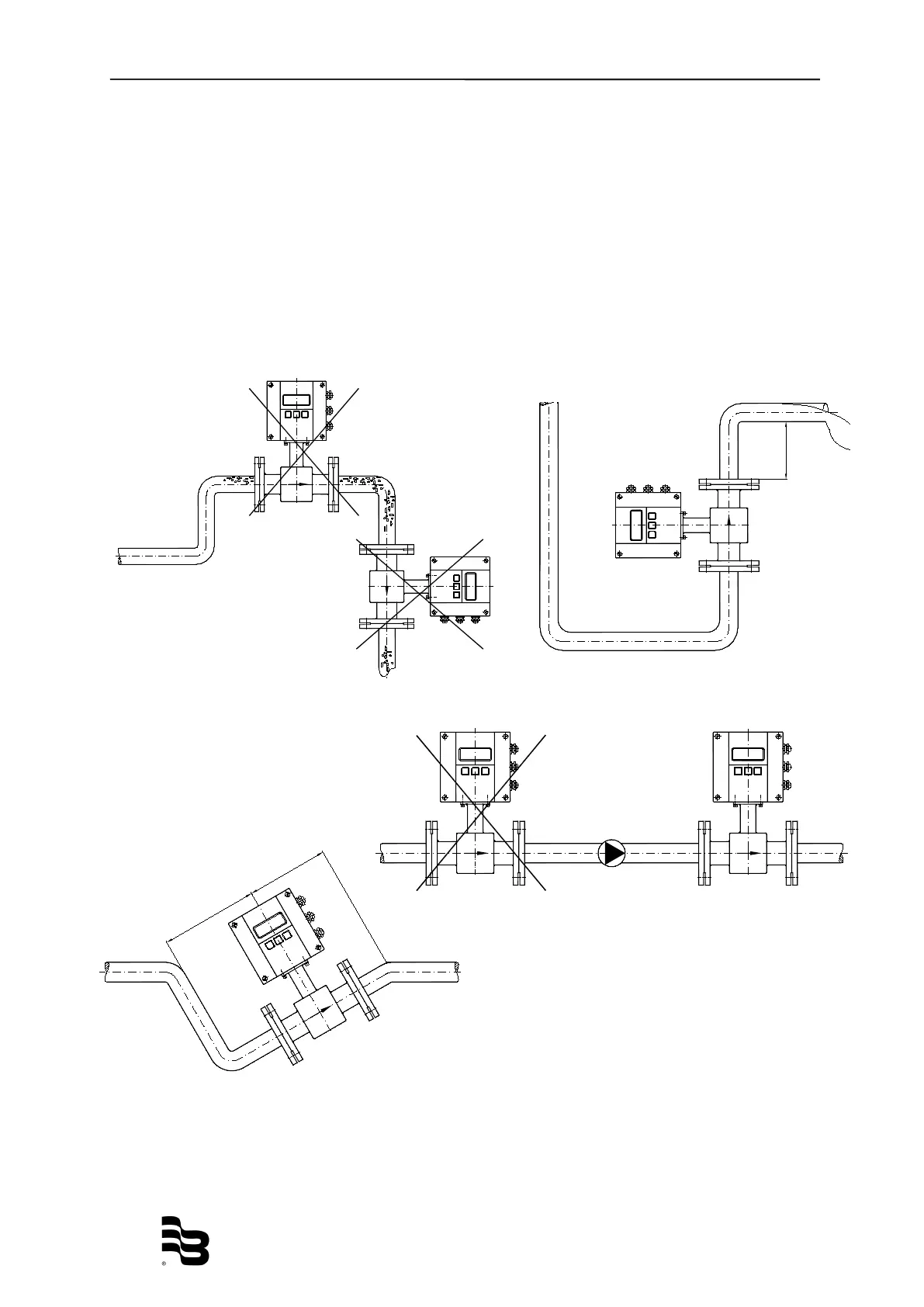

> 3-5 x DN

> 2 x DN

BA2000-13-MID

3.2.3 Meter location

Caution: • Do not install the detector on the suction sides of pumps. This could

damage the liner (in particular PTFE liners).

• Verify that the pipeline is always filled on the measuring point, if not - a

correct or accurate measurement is not possible.

• Do not install the detector on the highest point of a pipeline system. Gas

accumulation may follow.

• Do not install the detector in downcomer pipes with free outlet.

• Do not install the detector on pipes with vibrations. If pipes are strongly

vibrating, make sure that detector and amplifier are separated (separate

version).

Loading...

Loading...