Installation Page 6/51

MID_M2000_BA_02_1807

3.2.4 Pipe reducer requirements

With pipe reducers as per DIN 28545 detectors can be mounted in larger pipelines.

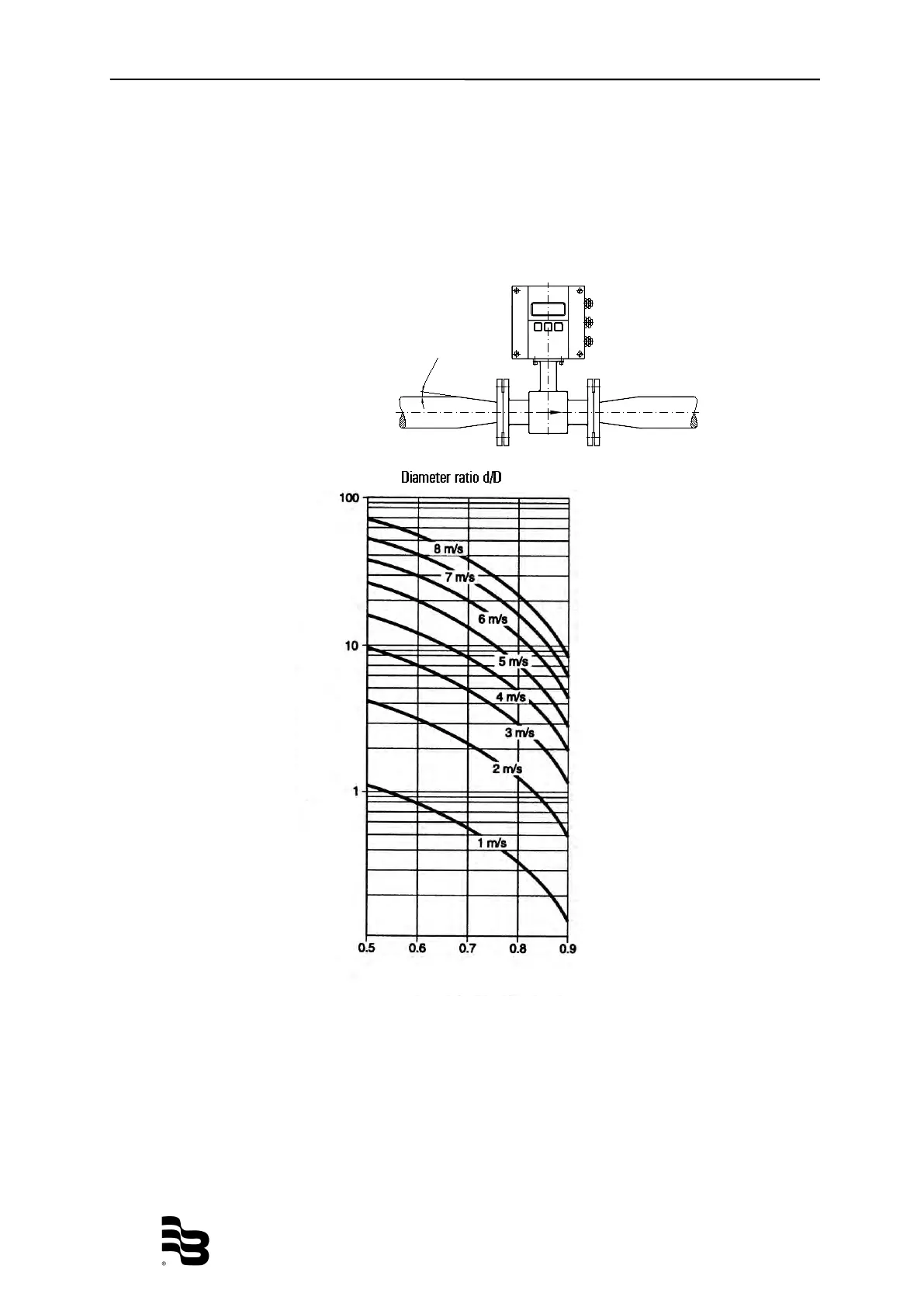

You can determine the occurring pressure drop by using the shown nomogram (only

applicable to liquids with similar viscosity like water).

Note: • In cases where flow velocities are very low, you can increment them by

reducing the size on the measuring point and hence obtain a better

measuring accuracy.

Define pressure loss:

1. Calculate diameter ratio d/D.

2. Read pressure loss depending on d/D ratio and flow velocity.

D = pipeline

d = detector

Loading...

Loading...