10 english

4

Installation and connection (continued)

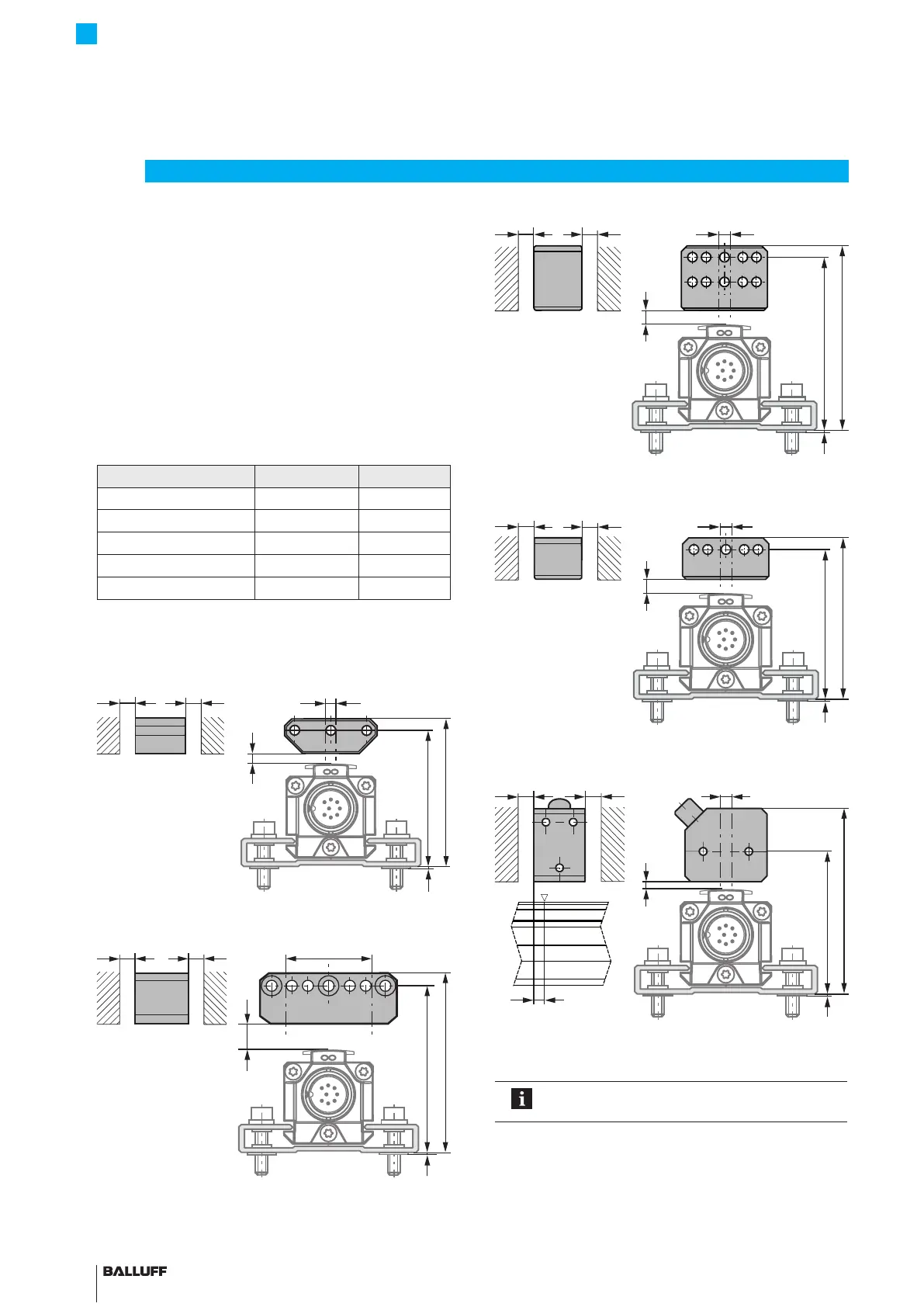

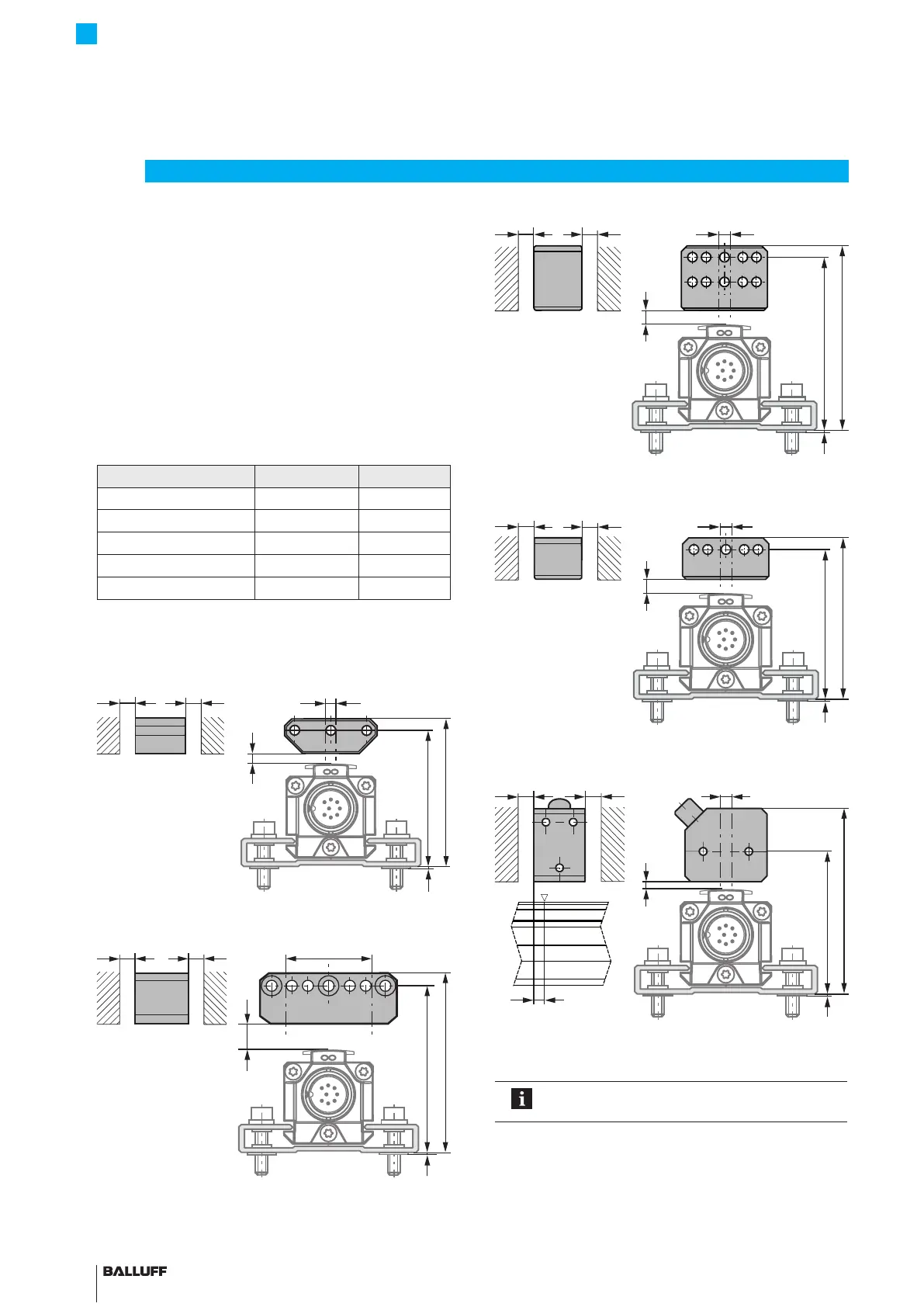

4.3 Floating magnets

The following must be observed when installing the magnet:

– To ensure the accuracy of the position measuring

system, the magnet is attached to the moving member

of the machine using non-magnetizable screws

(stainless steel, brass, aluminum).

– The moving member must guide the magnet on a track

parallel to the transducer.

– Ensure that the distanceA between the magnet and

parts made of magnetizable material is at least 10mm

(see Fig. 4-4 to Fig. 4-8).

– Maintain the following values for distanceB between

the magnet and transducer and for center offsetC

(see Fig. 4-4 to Fig. 4-8):

Type of magnet DistanceB

1)

OffsetC

BTL5-P-3800-2 0.1…4mm ±2mm

BTL5-P-5500-2 5…15mm ±15mm

BTL5-P-4500-1 0.1…2mm ±2mm

BTL6-A-3800-2 4…8mm

2)

±5mm

BTL6-A-3801-2 4…8mm

2)

±5mm

1)

The selected distance must stay constant over the entire measuring length.

2)

For optimum measurement results, a distanceB of 6 to 8 mm is

recommended.

Tab. 4-2: Distance and offset for floating magnets

Fig. 4-4:

B

50+4

55+4

1

Dimensions and distances with BTL5-P-3800-2 magnet

Fig. 4-5:

B

1

61+10

66+10

Dimensions and distances with BTL5-P-5500-2 magnet

Fig. 4-6:

B

1

74+4

69+4

Dimensions and distances with BTL6-A-3800-2 magnet

Fig. 4-7:

B

A

A

1

63+4

58+4

Dimensions and distances with BTL6-A-3801-2 magnet

Fig. 4-8:

B

A

A

4

1

81+2

57.5+2

Dimensions and distances with BTL5-P-4500-1

electromagnet (24V/100mA)

The measuring range is offset by 4mm towards

the transducer plug (see Fig. 4-8).

Plug with

LED

BTL7-P511 -M ____ -P-S32/S115/KA_ _

Micropulse Transducer in a Profile Housing

Loading...

Loading...